Zirconium alloy cladding offers superior neutron transparency and corrosion resistance compared to stainless steel, making it the preferred choice for fuel rod cladding in nuclear reactors. Its low neutron absorption cross-section enhances reactor efficiency, while its excellent behavior under high-temperature and high-radiation environments ensures fuel integrity. Stainless steel, while mechanically robust, exhibits higher neutron absorption and greater susceptibility to corrosion, limiting its effectiveness in cladding applications.

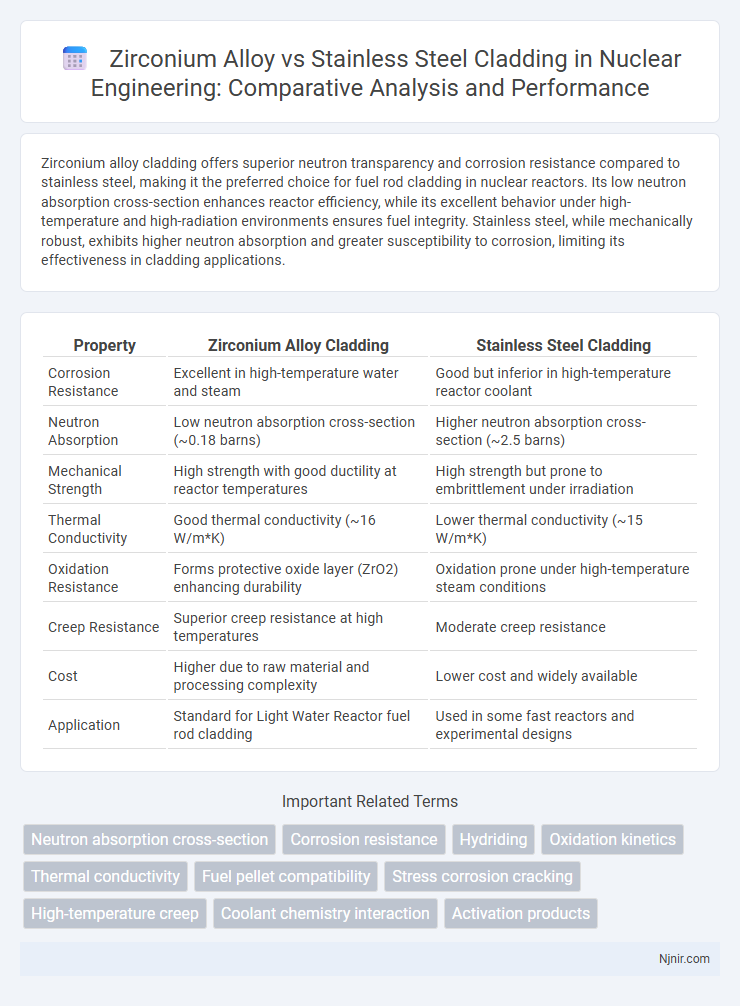

Table of Comparison

| Property | Zirconium Alloy Cladding | Stainless Steel Cladding |

|---|---|---|

| Corrosion Resistance | Excellent in high-temperature water and steam | Good but inferior in high-temperature reactor coolant |

| Neutron Absorption | Low neutron absorption cross-section (~0.18 barns) | Higher neutron absorption cross-section (~2.5 barns) |

| Mechanical Strength | High strength with good ductility at reactor temperatures | High strength but prone to embrittlement under irradiation |

| Thermal Conductivity | Good thermal conductivity (~16 W/m*K) | Lower thermal conductivity (~15 W/m*K) |

| Oxidation Resistance | Forms protective oxide layer (ZrO2) enhancing durability | Oxidation prone under high-temperature steam conditions |

| Creep Resistance | Superior creep resistance at high temperatures | Moderate creep resistance |

| Cost | Higher due to raw material and processing complexity | Lower cost and widely available |

| Application | Standard for Light Water Reactor fuel rod cladding | Used in some fast reactors and experimental designs |

Introduction to Cladding Materials in Nuclear Reactors

Zirconium alloys and stainless steel are critical cladding materials in nuclear reactors, serving as the primary barrier between nuclear fuel and the reactor coolant. Zirconium alloys are preferred for their low neutron absorption cross-section and excellent corrosion resistance under high-temperature water environments, enhancing reactor efficiency and safety. In contrast, stainless steel offers superior mechanical strength and radiation resistance but has a higher neutron absorption rate, making it less favorable for certain reactor designs.

Overview of Zirconium Alloy Cladding

Zirconium alloy cladding, widely used in nuclear reactors, offers exceptional corrosion resistance and low neutron absorption, enhancing fuel efficiency and safety. Its excellent mechanical properties at high temperatures enable it to maintain structural integrity under harsh reactor conditions. Compared to stainless steel cladding, zirconium alloys provide superior performance in radiation environments and reduced risk of chemical degradation.

Overview of Stainless Steel Cladding

Stainless steel cladding offers exceptional corrosion resistance and mechanical strength, making it ideal for applications in harsh environments such as chemical processing and marine industries. Its high chromium content forms a passive oxide layer that protects against oxidation and pitting, outperforming many materials in durability. Compared to zirconium alloy cladding, stainless steel cladding provides enhanced wear resistance and easier fabrication without compromising thermal performance.

Neutronic Properties Comparison

Zirconium alloy cladding exhibits significantly lower neutron absorption cross-section compared to stainless steel, enhancing neutron economy in nuclear reactors. Its superior neutronic properties contribute to higher fuel burnup efficiency and reduced parasitic neutron loss, essential for reactor core performance. Stainless steel cladding, with higher neutron absorption, detrimentally affects reactivity margins and neutron flux distribution within the reactor core.

Corrosion Resistance under Reactor Conditions

Zirconium alloy cladding exhibits superior corrosion resistance under typical reactor conditions due to its low neutron absorption cross-section and ability to form a stable, protective oxide layer in high-temperature water environments. Stainless steel cladding, while mechanically robust, tends to suffer from higher corrosion rates and stress corrosion cracking in pressurized water reactor (PWR) environments. Zirconium alloys specifically minimize hydrogen uptake and maintain structural integrity, ensuring enhanced lifespan and safety of nuclear fuel assemblies.

Mechanical Strength and Structural Integrity

Zirconium alloy cladding exhibits superior mechanical strength and corrosion resistance at high temperatures compared to stainless steel, maintaining its structural integrity under extreme reactor conditions. Stainless steel cladding, while offering excellent toughness and resistance to irradiation-induced swelling, generally demonstrates lower creep resistance and higher susceptibility to stress corrosion cracking than zirconium alloys. The enhanced mechanical performance of zirconium alloys contributes to safer and more efficient nuclear fuel containment during prolonged operation cycles.

Response to High-Temperature Accidents

Zirconium alloy cladding exhibits superior resistance to high-temperature accidents due to its low neutron absorption and excellent corrosion resistance, which minimizes hydrogen generation and reduces the risk of cladding failure under severe conditions. Stainless steel cladding, while offering greater mechanical strength and oxidation resistance, tends to have higher neutron absorption and may produce more hydrogen during high-temperature exposure, increasing the potential for embrittlement and failure. The choice between zirconium alloy and stainless steel cladding critically impacts reactor safety margins during loss-of-coolant accidents and other high-temperature scenarios in nuclear reactors.

Radioactive Waste Management Implications

Zirconium alloy cladding exhibits low neutron absorption and superior corrosion resistance, reducing the risk of cladding degradation and radioactive leakage in nuclear fuel applications compared to stainless steel cladding. The enhanced chemical stability of zirconium alloys minimizes radionuclide release during long-term storage and disposal of radioactive waste, improving containment safety. Stainless steel cladding, while mechanically robust, tends to have higher neutron absorption rates and increased susceptibility to corrosion under radioactive environments, potentially complicating waste management strategies.

Economic Considerations and Lifecycle Costs

Zirconium alloy cladding typically incurs higher upfront material and fabrication costs compared to stainless steel, driven by its superior corrosion resistance and neutron economy in nuclear reactors. Lifecycle costs favor zirconium alloys due to reduced maintenance, longer service intervals, and enhanced fuel efficiency, which lower overall operational expenses despite the initial investment. Stainless steel cladding, while cheaper initially, often demands more frequent inspections and replacements, increasing cumulative costs over the fuel cycle.

Future Prospects and Research Directions

Zirconium alloy cladding remains a focal point in nuclear reactor innovation due to its superior neutron economy and corrosion resistance compared to stainless steel cladding. Future research emphasizes enhancing zirconium alloys' resistance to high-temperature oxidation and radiation damage to extend fuel life and safety margins. Advanced coating techniques and alloying strategies are being explored to overcome current limitations and enable next-generation reactor designs with improved performance and sustainability.

Neutron absorption cross-section

Zirconium alloy cladding exhibits a significantly lower neutron absorption cross-section than stainless steel, enhancing nuclear reactor efficiency by minimizing neutron loss during fission.

Corrosion resistance

Zirconium alloy cladding exhibits superior corrosion resistance compared to stainless steel, especially in high-temperature and high-radiation environments typical of nuclear reactors.

Hydriding

Zirconium alloy cladding exhibits superior resistance to hydriding compared to stainless steel cladding, making it more reliable for preventing hydrogen-induced embrittlement in nuclear reactor environments.

Oxidation kinetics

Zirconium alloy cladding exhibits significantly slower oxidation kinetics than stainless steel cladding, resulting in enhanced corrosion resistance and improved high-temperature performance in nuclear reactor environments.

Thermal conductivity

Zirconium alloy cladding exhibits significantly higher thermal conductivity than stainless steel, enhancing heat transfer efficiency in nuclear reactor fuel rods.

Fuel pellet compatibility

Zirconium alloy cladding offers superior fuel pellet compatibility due to its low neutron absorption and excellent corrosion resistance compared to stainless steel cladding.

Stress corrosion cracking

Zirconium alloy cladding exhibits superior resistance to stress corrosion cracking compared to stainless steel cladding in nuclear reactor environments.

High-temperature creep

Zirconium alloy cladding exhibits superior high-temperature creep resistance compared to stainless steel, making it more reliable for prolonged use in nuclear reactor environments.

Coolant chemistry interaction

Zirconium alloy cladding exhibits superior corrosion resistance and lower hydrogen pickup in high-temperature water coolant chemistry compared to stainless steel, leading to enhanced fuel integrity and reduced oxide formation.

Activation products

Zirconium alloy cladding generates significantly fewer and less hazardous activation products such as ^95Zr and ^89Sr compared to stainless steel cladding, which produces higher levels of long-lived isotopes like ^60Co and ^59Ni, impacting nuclear waste management and radiation safety.

zirconium alloy vs stainless steel cladding Infographic

njnir.com

njnir.com