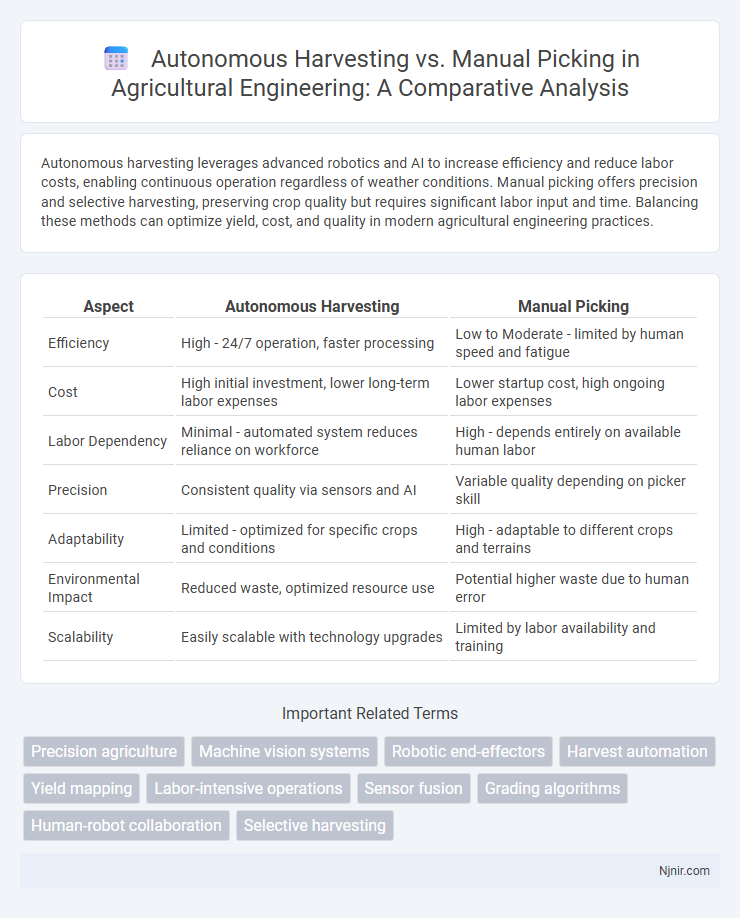

Autonomous harvesting leverages advanced robotics and AI to increase efficiency and reduce labor costs, enabling continuous operation regardless of weather conditions. Manual picking offers precision and selective harvesting, preserving crop quality but requires significant labor input and time. Balancing these methods can optimize yield, cost, and quality in modern agricultural engineering practices.

Table of Comparison

| Aspect | Autonomous Harvesting | Manual Picking |

|---|---|---|

| Efficiency | High - 24/7 operation, faster processing | Low to Moderate - limited by human speed and fatigue |

| Cost | High initial investment, lower long-term labor expenses | Lower startup cost, high ongoing labor expenses |

| Labor Dependency | Minimal - automated system reduces reliance on workforce | High - depends entirely on available human labor |

| Precision | Consistent quality via sensors and AI | Variable quality depending on picker skill |

| Adaptability | Limited - optimized for specific crops and conditions | High - adaptable to different crops and terrains |

| Environmental Impact | Reduced waste, optimized resource use | Potential higher waste due to human error |

| Scalability | Easily scalable with technology upgrades | Limited by labor availability and training |

Introduction to Harvesting Methods in Agriculture

Autonomous harvesting employs advanced robotics and AI technologies to improve efficiency, precision, and reduce labor costs in agriculture. Manual picking, while labor-intensive, allows for selective harvesting and adaptability to varied crop conditions, preserving fruit quality. The choice between these methods depends on crop type, farm scale, and economic factors influencing productivity and sustainability.

Technological Advancements in Autonomous Harvesting

Autonomous harvesting leverages cutting-edge technologies such as AI, robotics, and computer vision to optimize crop collection efficiency and reduce labor costs. Advanced sensors and machine learning algorithms enable precision in identifying ripe produce, enhancing yield quality and minimizing waste. Continuous improvements in automation hardware and software accelerate the transition from manual picking, boosting agricultural productivity on a large scale.

Key Differences Between Manual and Automated Picking

Automated picking systems utilize advanced robotics and AI technologies to enhance speed, accuracy, and efficiency in harvesting, reducing labor costs and minimizing crop damage. Manual picking relies on human labor, allowing for selective harvesting and adaptability to complex plant structures but often results in slower throughput and higher labor expenses. Key distinctions include consistency in picking quality, operational scalability, and the initial investment required for automation versus the flexibility and precision of manual methods.

Efficiency and Productivity Comparison

Autonomous harvesting systems utilize advanced robotics and AI algorithms to achieve higher efficiency, reducing labor costs and harvesting time compared to manual picking. These systems consistently operate with precision, minimizing crop damage and ensuring more uniform product quality, which significantly boosts overall productivity. Manual picking, while flexible in handling delicate crops, often suffers from slower throughput and increased labor variability impacting efficiency.

Economic Impacts: Cost Analysis of Both Methods

Autonomous harvesting significantly reduces labor costs by minimizing manual workforce requirements and increasing operational efficiency, resulting in lower long-term expenses despite high initial investment in technology and machinery. Manual picking, while having lower upfront costs, incurs higher ongoing labor expenses due to wages, benefits, and seasonal labor shortages. Economic analysis reveals autonomous systems offer improved cost-effectiveness in large-scale farming operations through enhanced productivity and reduced dependency on fluctuating labor markets.

Effects on Crop Quality and Yield

Autonomous harvesting employs advanced sensors and robotic precision to minimize crop damage, often resulting in higher quality produce with uniform ripeness compared to manual picking. This technology reduces human error and labor variability, enhancing yield consistency across large-scale operations. Conversely, manual picking allows selective harvesting that can preserve delicate crops but may cause inconsistent quality and slower harvest times, potentially lowering overall yield efficiency.

Labor Implications and Workforce Adaptation

Autonomous harvesting reduces reliance on manual labor, addressing labor shortages and lowering operational costs in agriculture. The shift requires workforce adaptation through reskilling programs focused on operating and maintaining advanced harvesting technology. Integrating robotics into farming transforms labor dynamics, emphasizing technical expertise over traditional labor-intensive roles.

Environmental Considerations in Harvesting Approaches

Autonomous harvesting reduces soil compaction and fuel emissions by optimizing machinery routes and operating with greater precision compared to manual picking. Manual harvesting often involves intensive human labor, which can lead to less consistent crop handling and increased waste, whereas autonomous systems enable real-time monitoring to minimize crop damage and optimize yield quality. Environmental benefits of autonomous harvesting include lower carbon footprints and enhanced sustainability through decreased resource usage and improved land management practices.

Challenges Facing Autonomous Harvesting Adoption

Autonomous harvesting faces significant challenges including complex crop variability, the high cost of advanced robotics, and the need for precise machine learning algorithms to handle diverse agricultural environments. Inconsistent weather conditions and the intricacies of delicate crop handling further complicate the deployment of automated systems. These factors contribute to slower adoption rates compared to manual picking, which remains dominant due to its adaptability and lower initial investment.

Future Prospects and Innovations in Harvesting Technologies

Autonomous harvesting technologies leverage advanced robotics, AI-powered vision systems, and precision agriculture to increase efficiency and reduce labor costs, with innovations such as drone-assisted crop monitoring and AI-driven yield prediction enhancing future prospects. Emerging developments in soft robotics and machine learning algorithms enable autonomous systems to handle delicate fruits with minimal damage, promising to redefine harvesting standards in various crop sectors. Continued integration of IoT, edge computing, and big data analytics is expected to optimize real-time decision-making and operational scalability, positioning autonomous harvesting as a transformative force in sustainable agriculture.

Precision agriculture

Autonomous harvesting in precision agriculture enhances efficiency and crop yield accuracy by using advanced sensors and AI for precise fruit detection and minimal crop damage compared to manual picking.

Machine vision systems

Machine vision systems in autonomous harvesting enable precise crop identification and quality assessment, significantly enhancing efficiency and reducing labor costs compared to manual picking.

Robotic end-effectors

Robotic end-effectors in autonomous harvesting improve precision and speed while reducing labor costs compared to traditional manual picking methods.

Harvest automation

Autonomous harvesting systems increase efficiency and reduce labor costs by employing advanced robotics and AI technology to automate crop collection compared to traditional manual picking methods.

Yield mapping

Autonomous harvesting with integrated yield mapping technology provides real-time, precise data on crop output, significantly enhancing accuracy and efficiency compared to manual picking methods.

Labor-intensive operations

Autonomous harvesting reduces labor-intensive operations by increasing efficiency and minimizing human intervention compared to manual picking.

Sensor fusion

Sensor fusion in autonomous harvesting integrates data from cameras, LiDAR, and infrared sensors to enhance fruit detection accuracy and picking precision compared to manual picking.

Grading algorithms

Grading algorithms in autonomous harvesting use computer vision and machine learning to accurately assess fruit size, color, and ripeness, achieving higher consistency and efficiency compared to manual picking.

Human-robot collaboration

Human-robot collaboration in autonomous harvesting enhances efficiency and reduces labor costs by combining robotic precision with human decision-making and adaptability.

Selective harvesting

Selective autonomous harvesting enhances crop yield accuracy and reduces labor costs by precisely targeting ripe produce compared to manual picking.

Autonomous harvesting vs manual picking Infographic

njnir.com

njnir.com