Fermentation bioreactors offer controlled environments with precise regulation of temperature, pH, and nutrient supply, enhancing algae productivity and consistency compared to open pond systems. Open pond systems have lower operational costs and simpler construction but face challenges such as contamination, variable environmental conditions, and lower biomass yields. Optimizing bioreactor design improves scalability and efficiency, making them the preferred choice for high-value algal products in agricultural engineering.

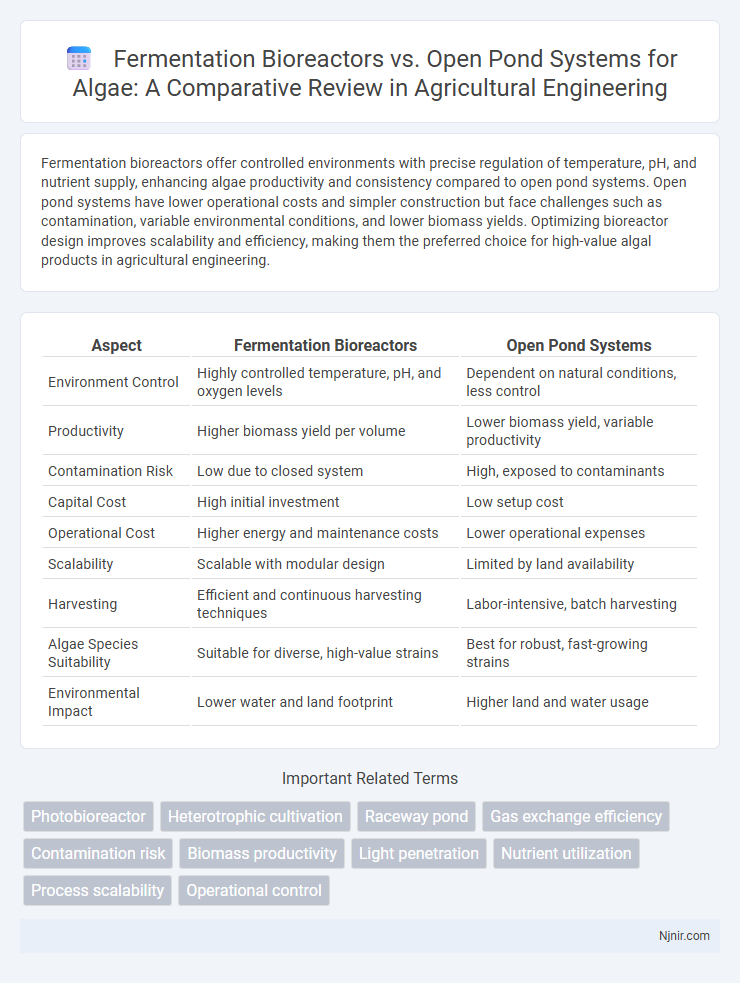

Table of Comparison

| Aspect | Fermentation Bioreactors | Open Pond Systems |

|---|---|---|

| Environment Control | Highly controlled temperature, pH, and oxygen levels | Dependent on natural conditions, less control |

| Productivity | Higher biomass yield per volume | Lower biomass yield, variable productivity |

| Contamination Risk | Low due to closed system | High, exposed to contaminants |

| Capital Cost | High initial investment | Low setup cost |

| Operational Cost | Higher energy and maintenance costs | Lower operational expenses |

| Scalability | Scalable with modular design | Limited by land availability |

| Harvesting | Efficient and continuous harvesting techniques | Labor-intensive, batch harvesting |

| Algae Species Suitability | Suitable for diverse, high-value strains | Best for robust, fast-growing strains |

| Environmental Impact | Lower water and land footprint | Higher land and water usage |

Introduction to Algae Cultivation Methods

Fermentation bioreactors offer a controlled environment for algae cultivation, enabling optimized temperature, pH, and nutrient availability, which enhances biomass yield and purity. Open pond systems are cost-effective and scalable but face challenges such as contamination, variable environmental conditions, and lower productivity. Selecting between fermentation bioreactors and open pond systems depends on production goals, resource availability, and desired quality of algal biomass.

Overview of Fermentation Bioreactors

Fermentation bioreactors provide a controlled environment for algae cultivation, optimizing factors such as temperature, pH, oxygen levels, and nutrient supply to enhance biomass productivity and metabolic activity. These closed systems minimize contamination risks and allow precise manipulation of growth parameters, resulting in higher yields of specific algal strains compared to open pond systems. Fermentation bioreactors support scalable, consistent algae production suitable for high-value bioactive compounds, biofuels, and pharmaceuticals.

Open Pond Systems: Concept and Design

Open pond systems for algae cultivation utilize shallow, raceway-shaped channels that enable natural sunlight and atmospheric carbon dioxide absorption to optimize photosynthesis. These systems are designed for cost-effective large-scale biomass production, leveraging simple water circulation methods such as paddle wheels to maintain algal suspension and nutrient distribution. Key factors in open pond design include controlling temperature, pH, and contamination risks to maximize algal growth rates and biomass yield efficiently.

Productivity Comparison: Bioreactors vs Open Ponds

Fermentation bioreactors offer significantly higher productivity than open pond systems for algae cultivation, achieving biomass concentrations up to 100 times greater due to controlled environmental conditions such as temperature, pH, and nutrient supply. Open pond systems typically exhibit lower productivity with biomass concentrations ranging between 0.1 to 1 g/L, subject to natural fluctuations and contamination risks. The enhanced control in bioreactors results in faster growth rates and increased lipid yields, making them preferable for commercial-scale algae biofuel and bioproduct production despite higher operational costs.

Capital and Operational Costs Analysis

Fermentation bioreactors for algae cultivation involve higher capital investment due to advanced equipment, controlled environments, and sterilization systems, whereas open pond systems require significantly lower initial costs with simpler infrastructure and minimal technology. Operational costs in fermentation bioreactors are driven by energy consumption for mixing, aeration, and temperature control, alongside microbial contamination management, while open ponds have reduced energy demands but face higher risks of contamination and lower productivity, impacting overall cost efficiency. The choice between these systems hinges on balancing the high capital and operational expenditures of fermentation reactors against the scalability and cost advantages of open ponds with varying yield and quality outcomes.

Environmental Impact and Sustainability

Fermentation bioreactors for algae cultivation offer controlled environments that minimize land use and reduce water evaporation compared to open pond systems, leading to lower environmental footprints. Open pond systems, while simpler and less costly, are more susceptible to contamination, water loss, and require larger land areas, raising concerns over sustainability in water-scarce regions. The closed nature of fermentation bioreactors enhances resource efficiency and decreases greenhouse gas emissions, promoting a more sustainable approach to algae biomass production.

Contamination Risks and Management

Fermentation bioreactors offer controlled environments with reduced contamination risks compared to open pond systems, as they operate in closed vessels minimizing exposure to airborne contaminants and competing microorganisms. Open pond systems face higher contamination risks due to their exposure to environmental pollutants, predators, and invasive algal species, requiring rigorous monitoring and management strategies like chemical treatments and selective harvesting to maintain culture purity. Effective contamination management in bioreactors relies on sterile techniques and automated monitoring, while open ponds depend on physical barriers, frequent water quality assessments, and adaptive operational practices.

Scalability and Industrial Applications

Fermentation bioreactors offer superior scalability with controlled environmental conditions that enhance algae biomass productivity and allow for high-density cultivation crucial for industrial applications like biofuel and pharmaceutical production. Open pond systems, while cost-effective and simpler to implement, face limitations in scalability due to environmental variability, lower productivity, and contamination risks which restrict their use in large-scale, high-value industrial processes. Industrial adoption increasingly favors fermentation bioreactors for consistent output, process optimization, and integration into closed-loop systems supporting sustainable algae biomass production.

Quality and Yield of Algal Biomass

Fermentation bioreactors provide a controlled environment that optimizes temperature, pH, and nutrient supply, resulting in higher purity and consistent quality of algal biomass compared to open pond systems. The closed nature of fermentation bioreactors minimizes contamination risks, enhancing the yield and reliability of algal biomass production. Open pond systems often face variability in environmental conditions and contamination, leading to lower biomass concentration and fluctuating quality.

Future Trends in Algal Cultivation Technologies

Fermentation bioreactors offer precise environmental control, enabling higher biomass yields and consistent product quality compared to open pond systems, which are more susceptible to contamination and environmental fluctuations. Future trends in algal cultivation focus on integrating advanced sensor technologies and automation in fermentation bioreactors to optimize growth conditions and reduce operational costs. Innovations in hybrid systems combining the scalability of open ponds with the efficiency of bioreactors are expected to drive sustainable and economically viable algae production for biofuels and bioproducts.

Photobioreactor

Photobioreactors enable controlled, high-density algae cultivation with enhanced productivity and contamination prevention compared to open pond systems.

Heterotrophic cultivation

Heterotrophic cultivation in fermentation bioreactors offers controlled conditions and higher biomass productivity for algae compared to open pond systems, which are more susceptible to contamination and environmental fluctuations.

Raceway pond

Raceway pond systems offer cost-effective, large-scale algae cultivation with natural sunlight but lower biomass productivity and higher contamination risk compared to controlled, high-yield fermentation bioreactors.

Gas exchange efficiency

Fermentation bioreactors for algae achieve significantly higher gas exchange efficiency than open pond systems by maintaining controlled oxygen and carbon dioxide levels, optimizing growth rates and biomass productivity.

Contamination risk

Fermentation bioreactors offer significantly lower contamination risk compared to open pond systems for algae cultivation due to their closed, controlled environments.

Biomass productivity

Fermentation bioreactors achieve significantly higher biomass productivity in algae cultivation compared to open pond systems due to controlled environmental conditions and optimized nutrient supply.

Light penetration

Fermentation bioreactors provide controlled environments with no reliance on light penetration, enabling consistent algae cultivation, whereas open pond systems depend heavily on sunlight availability and suffer from limited light penetration, reducing photosynthetic efficiency.

Nutrient utilization

Fermentation bioreactors optimize nutrient utilization by providing controlled environments for algae growth, leading to higher nutrient uptake efficiency compared to the nutrient loss-prone open pond systems.

Process scalability

Fermentation bioreactors offer superior process scalability for algae cultivation through controlled environment and higher biomass productivity compared to open pond systems, which are limited by environmental variability and lower yield consistency.

Operational control

Fermentation bioreactors offer precise operational control over temperature, pH, oxygen levels, and contamination compared to open pond systems, which are subject to environmental variability and limited monitoring capabilities.

Fermentation bioreactors vs Open pond systems (for algae) Infographic

njnir.com

njnir.com