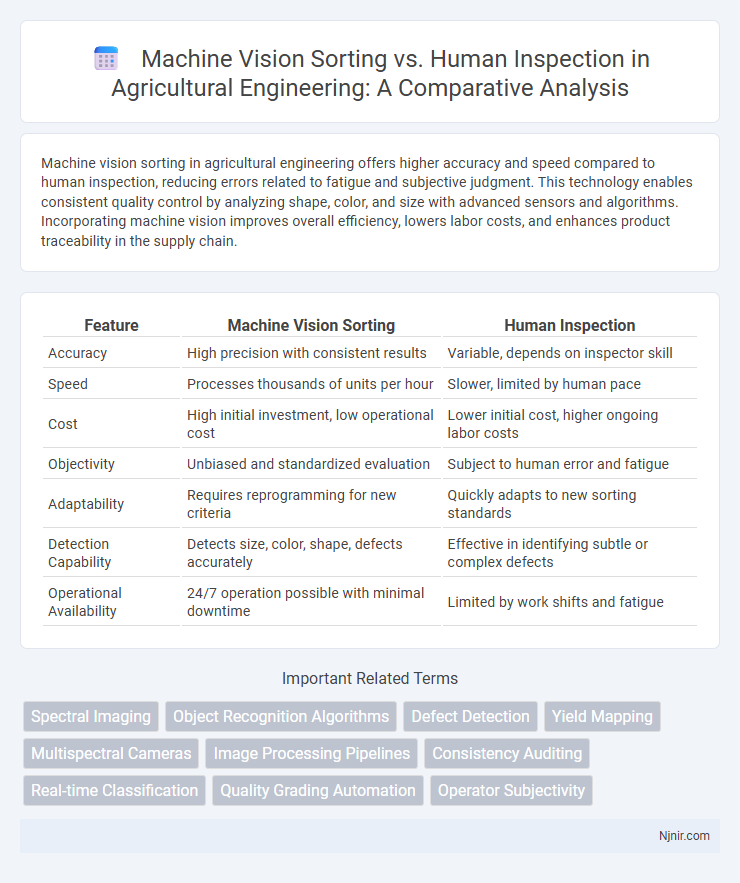

Machine vision sorting in agricultural engineering offers higher accuracy and speed compared to human inspection, reducing errors related to fatigue and subjective judgment. This technology enables consistent quality control by analyzing shape, color, and size with advanced sensors and algorithms. Incorporating machine vision improves overall efficiency, lowers labor costs, and enhances product traceability in the supply chain.

Table of Comparison

| Feature | Machine Vision Sorting | Human Inspection |

|---|---|---|

| Accuracy | High precision with consistent results | Variable, depends on inspector skill |

| Speed | Processes thousands of units per hour | Slower, limited by human pace |

| Cost | High initial investment, low operational cost | Lower initial cost, higher ongoing labor costs |

| Objectivity | Unbiased and standardized evaluation | Subject to human error and fatigue |

| Adaptability | Requires reprogramming for new criteria | Quickly adapts to new sorting standards |

| Detection Capability | Detects size, color, shape, defects accurately | Effective in identifying subtle or complex defects |

| Operational Availability | 24/7 operation possible with minimal downtime | Limited by work shifts and fatigue |

Introduction to Machine Vision Sorting and Human Inspection

Machine vision sorting utilizes advanced image processing algorithms and high-speed cameras to rapidly analyze and classify objects, ensuring consistent accuracy and efficiency in quality control processes. Human inspection relies on sensory perception and experience to identify defects and variations, but is subject to fatigue and inconsistencies over extended periods. Integrating machine vision technology enhances throughput and precision, outperforming traditional manual inspection in repetitive and large-scale sorting tasks.

Key Technologies in Machine Vision Sorting

Machine vision sorting leverages advanced technologies such as high-resolution cameras, deep learning algorithms, and real-time image processing to achieve superior accuracy and speed compared to human inspection. Key technologies include 3D vision systems for precise object recognition, hyperspectral imaging for material differentiation, and AI-driven pattern recognition that minimizes errors and improves consistency. These innovations enable automated sorting systems to handle complex tasks in manufacturing, agriculture, and recycling industries more efficiently than manual inspection methods.

Human Inspection: Traditional Practices and Limitations

Human inspection relies on manual visual assessment to identify defects and categorize products, often leading to inconsistent results due to subjective judgment and fatigue. Traditional practices depend heavily on the skill and experience of inspectors, which can result in variability and slower processing speeds. Limitations include decreased accuracy over time and difficulty in handling high volumes or minute defects compared to automated machine vision sorting systems.

Accuracy Comparison: Machine Vision vs Human Eye

Machine vision sorting systems achieve accuracy rates exceeding 99% by utilizing high-resolution cameras and advanced algorithms to detect defects and inconsistencies undetectable to the human eye. Human inspection accuracy varies widely, often falling between 70% and 85%, influenced by fatigue, subjective judgment, and environmental factors. The consistency and precision of machine vision enable superior defect detection and classification in industrial sorting applications compared to manual inspection.

Speed and Throughput Analysis

Machine vision sorting systems achieve significantly higher speed and throughput compared to human inspection, processing hundreds to thousands of items per minute with consistent accuracy. Advanced cameras and AI algorithms enable real-time defect detection and classification without fatigue, reducing bottlenecks in manufacturing and logistics. Human inspection, limited by physical and cognitive endurance, typically handles fewer items per hour and is prone to variability in performance under sustained workloads.

Consistency and Repeatability in Sorting

Machine vision sorting offers superior consistency and repeatability compared to human inspection by utilizing precise algorithms and high-resolution cameras that eliminate variability caused by human fatigue or subjective judgment. Automated systems maintain uniform accuracy throughout continuous operation, achieving consistent defect detection rates and reducing sorting errors. Human inspection, in contrast, often suffers from inconsistencies due to attention fluctuations and individual interpretation, leading to variability in sorting quality over time.

Cost Implications: Initial Investment and Long-term Savings

Machine vision sorting systems typically require a substantial initial investment, including high-quality cameras, lighting, and software integration, which can range from $50,000 to over $200,000 depending on complexity. Human inspection incurs lower upfront costs but involves continuous labor expenses, which can surpass automated system costs over time due to wages, training, and potential error rates. Over the long term, machine vision offers significant savings by reducing labor costs, increasing throughput, and improving consistency, often achieving ROI within 1 to 3 years.

Impact on Labor and Workforce Dynamics

Machine vision sorting significantly reduces the need for manual labor by automating repetitive inspection tasks, leading to increased productivity and lower labor costs. This technology shifts workforce dynamics by reallocating employees to more skilled roles focused on system maintenance, programming, and quality control analysis. Human inspection remains crucial for complex judgment calls but is becoming more specialized as machine vision enhances efficiency and scalability in quality assurance processes.

Application Case Studies in Agricultural Engineering

Machine vision sorting in agricultural engineering significantly enhances the accuracy and speed of quality assessment in crop sorting, reducing human error and labor costs while improving throughput. Case studies demonstrate that automated vision systems excel in detecting defects, size variations, and color inconsistencies in fruits and vegetables, outperforming human inspectors in both consistency and scalability. Human inspection, although flexible and adaptable to complex judgments, often encounters challenges related to fatigue and subjective bias, making machine vision a preferred solution for large-scale agricultural operations aiming for uniformity and efficiency.

Future Trends: Integration of AI and Enhanced Vision Systems

Machine vision sorting is rapidly advancing with the integration of AI algorithms, enabling higher accuracy and faster processing compared to traditional human inspection methods. Enhanced vision systems equipped with deep learning capabilities can detect complex defects and variations in real time, significantly reducing error rates and increasing throughput in manufacturing and quality control processes. Future trends indicate widespread adoption of AI-driven machine vision to optimize sorting efficiency, minimize labor costs, and improve overall product consistency across industries.

Spectral Imaging

Spectral imaging in machine vision sorting delivers faster, more precise material identification and defect detection than traditional human inspection, enhancing efficiency and accuracy in quality control processes.

Object Recognition Algorithms

Machine vision sorting utilizes advanced object recognition algorithms such as convolutional neural networks (CNNs) to achieve higher accuracy and speed compared to human inspection in identifying and classifying objects.

Defect Detection

Machine vision sorting detects defects with higher accuracy and consistency than human inspection, reducing error rates and increasing production efficiency.

Yield Mapping

Machine vision sorting enhances yield mapping accuracy by rapidly identifying defects and categorizing products with consistent precision compared to variable human inspection results.

Multispectral Cameras

Multispectral cameras in machine vision sorting enhance accuracy and speed by detecting material properties beyond human visual capabilities, significantly outperforming traditional human inspection in consistency and efficiency.

Image Processing Pipelines

Machine vision sorting uses advanced image processing pipelines with high-speed cameras and AI algorithms to achieve faster, more accurate, and consistent defect detection compared to variable human inspection.

Consistency Auditing

Machine vision sorting offers superior consistency auditing by eliminating human errors and providing uniform, objective evaluations across high-volume inspections.

Real-time Classification

Machine vision sorting achieves real-time classification with higher speed and accuracy than human inspection, reducing errors and increasing throughput in industrial applications.

Quality Grading Automation

Machine vision sorting automates quality grading with higher accuracy, speed, and consistency compared to human inspection, significantly reducing errors and operational costs.

Operator Subjectivity

Machine vision sorting eliminates operator subjectivity inherent in human inspection by providing consistent, objective, and data-driven analysis for higher accuracy and reliability.

Machine vision sorting vs human inspection Infographic

njnir.com

njnir.com