Robotics automation in agricultural engineering significantly enhances precision and efficiency by performing repetitive tasks such as planting, harvesting, and monitoring crop health with greater accuracy than human labor. Automated systems reduce the risk of human error and labor shortages, leading to increased productivity and cost savings for large-scale farms. However, integrating robotics requires substantial investment and technical expertise, presenting challenges for smallholder farmers relying on traditional manual labor.

Table of Comparison

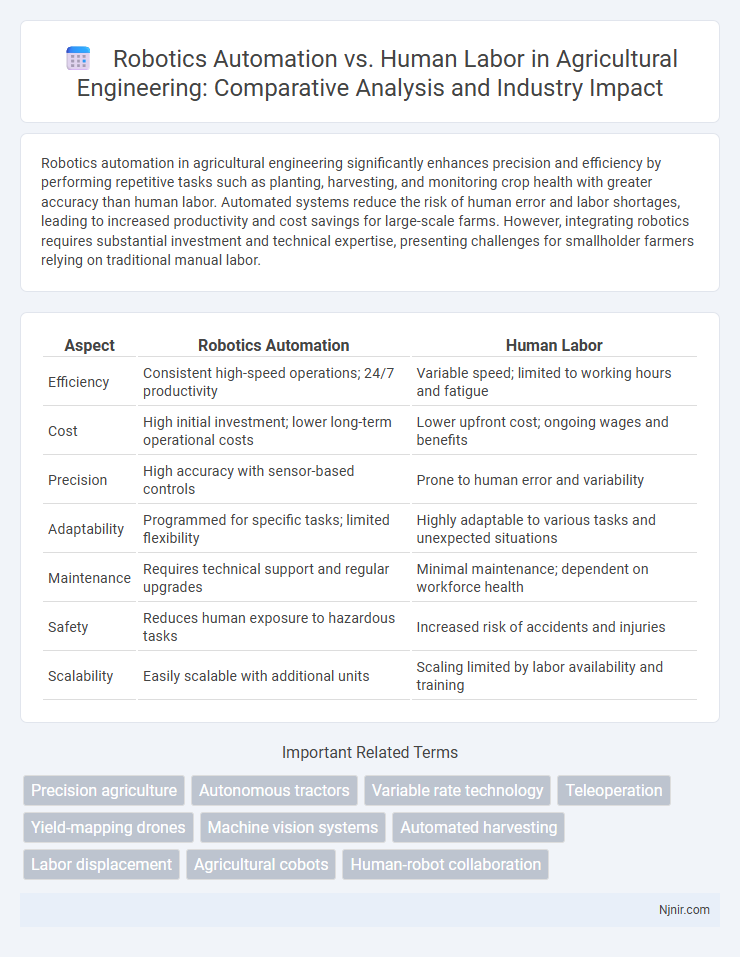

| Aspect | Robotics Automation | Human Labor |

|---|---|---|

| Efficiency | Consistent high-speed operations; 24/7 productivity | Variable speed; limited to working hours and fatigue |

| Cost | High initial investment; lower long-term operational costs | Lower upfront cost; ongoing wages and benefits |

| Precision | High accuracy with sensor-based controls | Prone to human error and variability |

| Adaptability | Programmed for specific tasks; limited flexibility | Highly adaptable to various tasks and unexpected situations |

| Maintenance | Requires technical support and regular upgrades | Minimal maintenance; dependent on workforce health |

| Safety | Reduces human exposure to hazardous tasks | Increased risk of accidents and injuries |

| Scalability | Easily scalable with additional units | Scaling limited by labor availability and training |

Introduction to Robotics Automation in Agriculture

Robotics automation in agriculture enhances efficiency by performing tasks such as planting, harvesting, and monitoring crops with precision and speed, reducing the reliance on human labor. Advanced technologies including autonomous tractors, drones, and robotic harvesters optimize resource use and increase productivity in farming operations. Adoption of robotic systems addresses labor shortages and minimizes human exposure to hazardous conditions in agricultural environments.

Evolution of Human Labor in Farming Practices

The evolution of human labor in farming practices has been significantly shaped by robotics automation, transforming traditional manual tasks such as planting, harvesting, and irrigation control. Advanced agricultural robots equipped with AI and machine learning enhance precision, efficiency, and crop yield while reducing the dependency on seasonal labor shortages. As robotics automation integrates further into farming, human roles shift towards supervision, maintenance, and decision-making, optimizing labor productivity and sustainability in agriculture.

Comparative Efficiency: Robots vs Human Workers

Robotics automation significantly outperforms human labor in repetitive tasks by delivering consistent precision and reducing error rates, leading to higher overall productivity. Robots operate continuously without fatigue, enabling uninterrupted workflows and faster cycle times compared to human workers. Despite initial setup costs, long-term savings in operational expenses and increased output efficiency make robotic systems a superior choice for large-scale manufacturing.

Cost Analysis: Automation Technology vs Manual Labor

Robotics automation reduces long-term operational costs by minimizing wages, benefits, and human error-related expenses, despite high initial investment and maintenance fees. Manual labor incurs ongoing costs tied to salaries, training, and turnover, which can escalate with scale and complexity. Cost analysis reveals that automation provides higher ROI in industries with repetitive tasks, while human labor remains cost-effective for jobs requiring flexibility and problem-solving skills.

Precision Agriculture: Benefits of Robotic Solutions

Robotics automation in precision agriculture significantly improves crop monitoring and management by enabling precise planting, watering, and harvesting, reducing waste and increasing yield. Robotic solutions equipped with advanced sensors and AI outperform human labor in consistency and accuracy, minimizing errors and optimizing resource use. Implementing robotics in agriculture enhances efficiency, lowers labor costs, and supports sustainable farming practices by targeting interventions exactly where needed.

Impact on Crop Yield and Quality

Robotics automation significantly enhances crop yield and quality by enabling precise planting, watering, and harvesting, which reduces human error and optimizes resource use. Automated systems utilize advanced sensors and AI to monitor crop health continuously, leading to timely interventions that improve growth conditions and minimize crop damage. While human labor offers adaptability and expert judgment, robotics ensures consistent performance and scalability, resulting in higher efficiency and improved agricultural productivity.

Labor Shortages and Robotics Adoption

Labor shortages across manufacturing and logistics sectors are accelerating the adoption of robotics automation to maintain productivity and operational efficiency. Robotics automation addresses workforce gaps by performing repetitive tasks, reducing dependency on human labor and minimizing downtime caused by employee absences or turnover. Companies investing in collaborative robots (cobots) and AI-driven automation technologies experience improved output quality and faster production cycles amid tightening labor markets.

Safety and Risk Factors for Humans and Robots

Robotics automation significantly reduces the risk of workplace injuries by performing hazardous tasks that expose human labor to physical harm, chemical exposure, and repetitive strain injuries. Advanced sensors and safety protocols integrated within robotic systems minimize collision risks and ensure safe human-robot interaction in shared workspaces. Despite these safety measures, human oversight remains essential to manage unexpected scenarios and maintain operational safety effectively.

Socioeconomic Implications of Automation

The socioeconomic implications of robotics automation versus human labor include significant shifts in employment patterns, wage disparities, and workforce skill requirements. Automation can lead to job displacement in routine and manual sectors while simultaneously creating demand for advanced technical roles, affecting income distribution and social mobility. Policymakers must address retraining programs, social safety nets, and equitable growth strategies to mitigate economic inequalities driven by increasing automation.

Future Trends: Integrating Robotics with Human Expertise

Future trends in robotics automation emphasize seamless integration with human expertise to enhance productivity and innovation. Collaborative robots, or cobots, are designed to work safely alongside humans, combining robotic precision with human creativity and problem-solving skills. This hybrid approach is expected to revolutionize industries by optimizing workflows, reducing errors, and enabling adaptive manufacturing processes.

Precision agriculture

Precision agriculture leverages robotics automation to enhance crop monitoring and harvesting accuracy, significantly outperforming human labor in efficiency and consistency.

Autonomous tractors

Autonomous tractors increase agricultural efficiency by reducing labor costs and minimizing human error compared to traditional human-operated machinery.

Variable rate technology

Variable rate technology in robotics automation enhances precision and efficiency by adjusting inputs dynamically, outperforming human labor in optimizing resource use and reducing operational costs.

Teleoperation

Teleoperation enhances robotics automation by enabling remote human control of machines, increasing precision and safety in hazardous environments while reducing the need for direct human labor.

Yield-mapping drones

Yield-mapping drones enhance agricultural efficiency by providing precise crop data, significantly outperforming human labor in accuracy and speed for yield analysis.

Machine vision systems

Machine vision systems in robotics automation enhance precision and efficiency, surpassing human labor in repetitive inspection tasks by reducing errors and accelerating throughput.

Automated harvesting

Automated harvesting in robotics automation significantly increases efficiency and reduces labor costs compared to traditional human labor in agriculture.

Labor displacement

Robotics automation accelerates labor displacement by replacing repetitive and manual tasks, significantly reducing demand for human labor in manufacturing and logistics sectors.

Agricultural cobots

Agricultural cobots enhance crop harvesting efficiency by automating repetitive tasks, reducing labor costs, and improving precision compared to traditional human labor.

Human-robot collaboration

Human-robot collaboration enhances productivity by combining robotic precision and human adaptability, driving efficiency in automation without replacing human labor.

robotics automation vs human labor Infographic

njnir.com

njnir.com