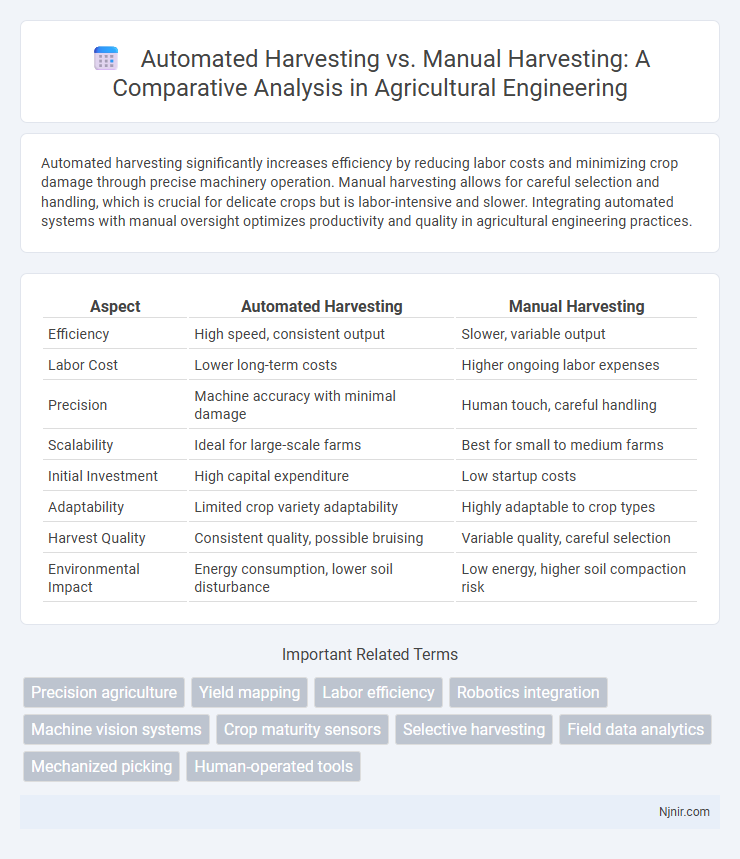

Automated harvesting significantly increases efficiency by reducing labor costs and minimizing crop damage through precise machinery operation. Manual harvesting allows for careful selection and handling, which is crucial for delicate crops but is labor-intensive and slower. Integrating automated systems with manual oversight optimizes productivity and quality in agricultural engineering practices.

Table of Comparison

| Aspect | Automated Harvesting | Manual Harvesting |

|---|---|---|

| Efficiency | High speed, consistent output | Slower, variable output |

| Labor Cost | Lower long-term costs | Higher ongoing labor expenses |

| Precision | Machine accuracy with minimal damage | Human touch, careful handling |

| Scalability | Ideal for large-scale farms | Best for small to medium farms |

| Initial Investment | High capital expenditure | Low startup costs |

| Adaptability | Limited crop variety adaptability | Highly adaptable to crop types |

| Harvest Quality | Consistent quality, possible bruising | Variable quality, careful selection |

| Environmental Impact | Energy consumption, lower soil disturbance | Low energy, higher soil compaction risk |

Introduction to Harvesting Methods in Agriculture

Automated harvesting employs machinery such as combine harvesters, which enhance efficiency and reduce labor costs by quickly gathering crops like wheat, corn, and soybeans. Manual harvesting relies on human labor, involving hand tools for precise selection and handling of delicate crops such as fruits and vegetables, ensuring minimal damage and quality control. Both methods vary in cost, speed, and suitability depending on crop type, farm size, and technology availability in agricultural practices.

Overview of Automated Harvesting Technologies

Automated harvesting technologies utilize advanced robotics, machine vision, and GPS-guided machinery to efficiently pick crops with minimal human intervention, significantly improving harvesting speed and consistency. These systems often incorporate AI algorithms to identify ripe produce, reducing crop damage and labor costs compared to manual harvesting methods. Innovations include autonomous tractors, robotic fruit pickers, and drone-based crop monitoring platforms that optimize yield and operational efficiency in modern agriculture.

Manual Harvesting: Processes and Labor Requirements

Manual harvesting involves skilled laborers using hand tools to carefully pick crops, ensuring minimal damage and selective harvesting based on crop maturity. This process demands significant human effort, providing flexibility to adapt to varying field conditions and crop types, but it is time-consuming and labor-intensive. Labor requirements include a trained workforce capable of handling delicate produce, often leading to higher operational costs compared to mechanized methods.

Efficiency Comparison: Speed and Yield

Automated harvesting systems significantly increase operational speed by utilizing advanced machinery capable of continuous work, covering larger areas faster than manual labor. These technologies optimize yield through precise, consistent harvesting techniques that reduce crop damage and minimize losses, resulting in higher quality produce. Manual harvesting, while offering selectivity and adaptability, generally lags in efficiency, with slower throughput and greater variability in harvest quality impacting overall productivity.

Economic Analysis: Costs and ROI

Automated harvesting significantly reduces labor costs by utilizing advanced machinery, leading to lower operational expenses compared to manual harvesting, which demands higher labor input and wages. Initial investment in automated equipment can be substantial, but the faster harvesting speed and increased efficiency improve ROI over time, especially in large-scale farming. Manual harvesting offers lower upfront costs but typically results in slower processing and variable labor expenses, which may hinder profitability in extensive agricultural operations.

Labor Impact and Workforce Considerations

Automated harvesting significantly reduces labor requirements by replacing manual tasks with technology, leading to decreased demand for seasonal farmworkers and mitigating labor shortages. While automation increases efficiency and consistency, it also necessitates workforce reskilling to manage and maintain sophisticated machinery. Manual harvesting, although labor-intensive and costly, supports rural employment and provides income opportunities in agricultural communities.

Crop Suitability and Harvesting Precision

Automated harvesting excels in uniformly cultivated crops like wheat, corn, and soybeans, where machinery can efficiently handle large-scale operations with consistent precision. Manual harvesting remains preferable for delicate or irregular crops such as fruits and vegetables, where human judgment ensures minimal damage and selective picking. Crop suitability for automated systems depends on uniformity and terrain, while harvesting precision hinges on the ability to preserve crop quality and reduce losses.

Environmental and Sustainability Implications

Automated harvesting reduces soil compaction and crop damage by utilizing precision machinery, leading to improved soil health and less waste compared to manual harvesting. It lowers labor intensity and increases efficiency, decreasing the carbon footprint through optimized fuel use and fewer passes over fields. Manual harvesting, while less energy-dependent, often results in higher labor emissions and inconsistent crop handling, which can affect long-term sustainability and resource management.

Adoption Challenges and Technology Integration

Automated harvesting faces significant adoption challenges including high initial capital investment, limited adaptability to diverse crop types, and the complexity of integrating advanced robotics with existing farm management systems. Manual harvesting remains prevalent due to its flexibility, lower upfront costs, and ease of use in irregular terrains and delicate crops, although it suffers from labor shortages and inconsistent productivity. Successful technology integration requires robust AI-driven sensors, machine learning algorithms, and user-friendly interfaces that align with farmers' operational workflows and regional agricultural practices.

Future Trends in Harvesting Automation

Automated harvesting is rapidly evolving with advancements in AI, robotics, and sensor technologies, enabling higher efficiency and precision compared to manual harvesting. Future trends indicate increasing adoption of autonomous machines equipped with machine learning algorithms to optimize crop selection and reduce labor costs. Integration of IoT devices and real-time data analytics will further enhance decision-making and operational productivity in precision agriculture.

Precision agriculture

Automated harvesting in precision agriculture enhances crop yield accuracy and efficiency by utilizing GPS-guided machinery and real-time data analysis compared to traditional manual harvesting.

Yield mapping

Automated harvesting systems enable precise yield mapping by integrating real-time data collection with GPS technology, resulting in higher accuracy and efficiency compared to manual harvesting methods.

Labor efficiency

Automated harvesting increases labor efficiency by reducing human labor requirements and accelerating crop collection compared to manual harvesting methods.

Robotics integration

Robotics integration in automated harvesting boosts efficiency, precision, and scalability compared to labor-intensive manual harvesting methods.

Machine vision systems

Machine vision systems in automated harvesting enhance accuracy and efficiency by precisely identifying crop ripeness and minimizing damage compared to labor-intensive manual harvesting.

Crop maturity sensors

Crop maturity sensors in automated harvesting systems enhance precision and efficiency by accurately determining optimal harvest times, surpassing the subjective assessments of manual harvesting.

Selective harvesting

Selective harvesting using automated systems increases efficiency and precision by targeting specific crops based on ripeness and quality, unlike manual harvesting which relies heavily on labor and is time-intensive.

Field data analytics

Automated harvesting leverages advanced field data analytics for real-time crop monitoring and precision harvesting, significantly increasing efficiency and yield accuracy compared to manual harvesting.

Mechanized picking

Mechanized picking in automated harvesting significantly increases efficiency and reduces labor costs compared to manual harvesting methods.

Human-operated tools

Human-operated tools in manual harvesting enhance precision and adaptability, while automated harvesting maximizes efficiency but may lack the nuanced control provided by skilled operators.

Automated harvesting vs Manual harvesting Infographic

njnir.com

njnir.com