PT100 sensors provide precise and stable temperature measurements by utilizing the predictable resistance change in platinum with temperature changes, making them ideal for applications requiring high accuracy and repeatability. Thermocouples, on the other hand, offer a wider temperature range and faster response times by measuring voltage generated at the junction of two dissimilar metals, which makes them suitable for harsh environments and rapid temperature variations. While PT100 sensors excel in stability and linearity, thermocouples are preferred for high-temperature applications due to their robustness and cost-effectiveness.

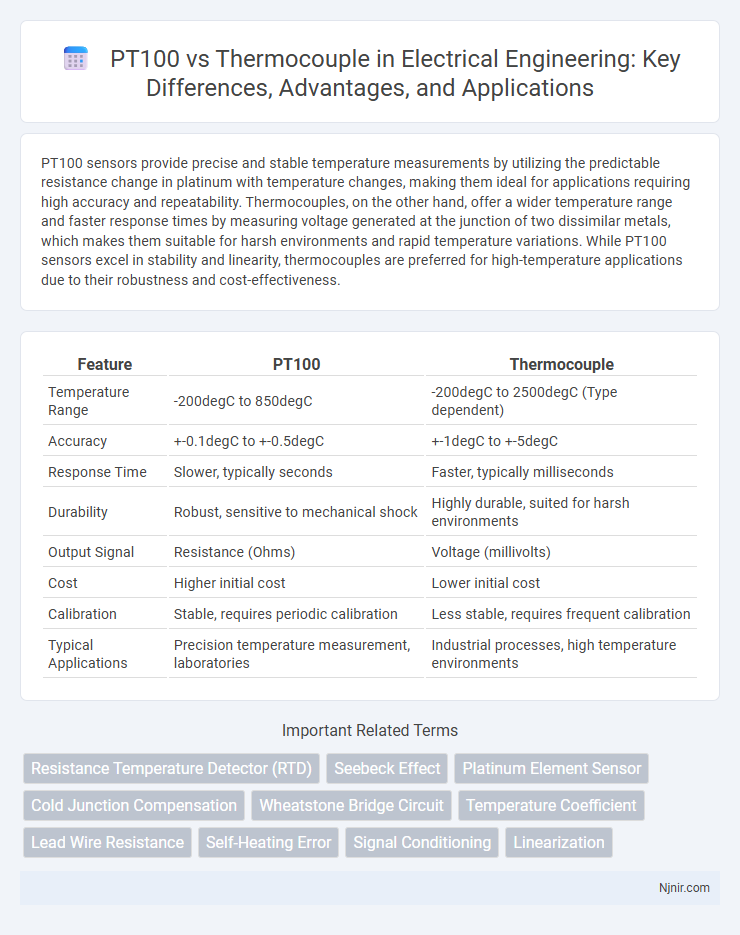

Table of Comparison

| Feature | PT100 | Thermocouple |

|---|---|---|

| Temperature Range | -200degC to 850degC | -200degC to 2500degC (Type dependent) |

| Accuracy | +-0.1degC to +-0.5degC | +-1degC to +-5degC |

| Response Time | Slower, typically seconds | Faster, typically milliseconds |

| Durability | Robust, sensitive to mechanical shock | Highly durable, suited for harsh environments |

| Output Signal | Resistance (Ohms) | Voltage (millivolts) |

| Cost | Higher initial cost | Lower initial cost |

| Calibration | Stable, requires periodic calibration | Less stable, requires frequent calibration |

| Typical Applications | Precision temperature measurement, laboratories | Industrial processes, high temperature environments |

Introduction to Temperature Sensors in Electrical Engineering

PT100 sensors offer precise resistance measurement based on platinum's predictable resistance change with temperature, widely used for accurate temperature control in electrical engineering applications. Thermocouples generate a voltage proportional to temperature difference between two dissimilar metals, enabling fast response and wide temperature range measurement in industrial environments. Selection between PT100 and thermocouple depends on factors like temperature range, accuracy needs, and environmental conditions in electrical engineering systems.

PT100: Principle of Operation and Key Features

PT100 sensors operate on the principle that the electrical resistance of platinum increases predictably with temperature, enabling precise temperature measurements. Platinum's stable and repeatable resistance-temperature relationship ensures high accuracy, linearity, and repeatability across a wide temperature range from -200degC to 850degC. Key features of PT100 include exceptional stability, corrosion resistance, and suitability for industrial processes requiring precise temperature control and monitoring.

Thermocouples: Types, Working Principle, and Applications

Thermocouples consist of two dissimilar metal wires joined at one end, generating a voltage proportional to temperature based on the Seebeck effect. Common types include Type K (Nickel-Chromium vs. Nickel-Alumel), Type J (Iron vs. Copper-Nickel), and Type T (Copper vs. Constantan), each offering specific temperature ranges and sensitivities ideal for industrial, scientific, and HVAC applications. Their robustness, wide temperature range (-200degC to 1350degC), and fast response make thermocouples suitable for processes requiring precise temperature monitoring and control.

Accuracy and Precision: PT100 vs Thermocouple

PT100 sensors provide higher accuracy and better precision in temperature measurement due to their stable resistance-temperature relationship and low drift over time. Thermocouples offer a wider temperature range but generally exhibit lower accuracy and sensitivity to electromagnetic interference, leading to less precise readings. For applications demanding exact temperature control, PT100 sensors are preferred, while thermocouples are suitable for broader temperature ranges and harsh environments.

Temperature Range Comparison

PT100 sensors operate effectively within a temperature range of approximately -200degC to 850degC, providing high accuracy and stability for moderate temperature measurements. Thermocouples cover a much broader temperature range, spanning from -200degC up to 2300degC depending on the type (e.g., Type K, Type J), making them suitable for extreme high-temperature environments. The choice between PT100 and thermocouples often depends on the required measurement range and the harshness of the application environment.

Response Time and Sensitivity

PT100 sensors offer slower response times, typically ranging from 1 to 5 seconds, due to the resistive element's thermal mass, while thermocouples respond much faster, often within milliseconds, because of their minimal thermal inertia. Sensitivity in PT100 sensors is relatively low, with a resistance change of approximately 0.385 ohms per degree Celsius, providing high accuracy and stability. Thermocouples exhibit higher sensitivity, generating millivolt signals directly proportional to temperature differences, enabling rapid detection of temperature fluctuations over a wide range.

Installation and Maintenance Considerations

PT100 sensors require careful wiring and connection to minimize signal loss and interference, often demanding shielded cables and proper grounding for accurate temperature measurement. Their maintenance involves periodic calibration and inspection to detect sensor drift or damage, ensuring consistent performance over time. Thermocouples offer simpler installation with fewer wiring requirements but may need frequent replacement or compensation for junction degradation and cold junction effects during maintenance.

Cost Analysis: PT100 vs Thermocouple

PT100 sensors typically have a higher upfront cost than thermocouples due to their platinum element and precision construction, making them more expensive to purchase. Thermocouples offer a cost-effective solution with lower initial investment and wider temperature range capabilities, suitable for many industrial applications. Long-term maintenance costs for PT100 sensors can be lower owing to their durability and stability, while thermocouples may require more frequent calibration and replacement.

Application Suitability in Industrial Settings

PT100 sensors offer high accuracy and stability for temperature measurement in industrial processes where precise control is critical, such as chemical manufacturing and pharmaceutical production. Thermocouples provide a wider temperature range and faster response times, making them suitable for high-temperature environments like metal forging and power plants. Choosing between PT100 and thermocouple depends on factors like temperature range, accuracy requirements, and environmental conditions within the industrial setting.

Choosing the Right Sensor: Key Decision Factors

PT100 sensors offer high accuracy and stability for temperature measurements in the range of -200degC to 850degC, making them ideal for precise industrial applications, while thermocouples cover a wider temperature range up to 2300degC and are better suited for high-temperature environments. Consider factors such as temperature range, response time, sensitivity, and environmental conditions when selecting between PT100 and thermocouples. Cost and durability also play crucial roles, with thermocouples generally being more rugged and cost-effective for harsh settings.

Resistance Temperature Detector (RTD)

PT100 is a highly accurate Resistance Temperature Detector (RTD) that measures temperature by correlating resistance changes in platinum to temperature variations, offering greater stability and precision compared to thermocouples.

Seebeck Effect

The PT100 sensor measures temperature through resistance changes in platinum, while thermocouples generate a voltage based on the Seebeck Effect, where the junction of two different metals produces a temperature-dependent electromotive force.

Platinum Element Sensor

The PT100 sensor, made from high-purity platinum, offers superior accuracy and stability in temperature measurement compared to thermocouples, which rely on metal junction voltage changes.

Cold Junction Compensation

PT100 sensors provide stable resistance-based temperature measurement while thermocouples require precise Cold Junction Compensation to accurately account for reference junction temperature variations.

Wheatstone Bridge Circuit

The PT100 sensor provides precise resistance measurements in Wheatstone Bridge circuits, enabling accurate temperature sensing with higher stability and linearity compared to thermocouples, which rely on voltage generation but may require cold-junction compensation for accuracy.

Temperature Coefficient

The PT100 sensor features a stable temperature coefficient of approximately 0.385 O/degC, enabling precise resistance changes with temperature, whereas thermocouples rely on the Seebeck effect with varying temperature coefficients depending on metal types, affecting their voltage output sensitivity.

Lead Wire Resistance

PT100 sensors exhibit lower susceptibility to lead wire resistance compared to thermocouples, ensuring more accurate temperature measurements over long cable runs.

Self-Heating Error

PT100 sensors exhibit lower self-heating error compared to thermocouples due to their higher electrical resistance and lower excitation currents, resulting in more accurate temperature measurements in sensitive applications.

Signal Conditioning

PT100 sensors provide precise resistance-based temperature signals requiring linearization and amplification, whereas thermocouples generate voltage signals needing cold-junction compensation and amplification for accurate signal conditioning.

Linearization

PT100 sensors exhibit superior linearity across temperature ranges compared to thermocouples, which require complex linearization algorithms due to their nonlinear voltage-temperature relationship.

PT100 vs thermocouple Infographic

njnir.com

njnir.com