MCCBs (Molded Case Circuit Breakers) offer reliable protection for low to medium voltage circuits with current ratings typically up to 1600A, making them ideal for residential and commercial applications. ACBs (Air Circuit Breakers) are designed for higher current capacities, often exceeding 1600A, and provide advanced features such as adjustable trip settings and better fault interruption capabilities suited for industrial environments. Selecting between MCCB and ACB depends on the required current rating, application scale, and protection level needed in the electrical system.

Table of Comparison

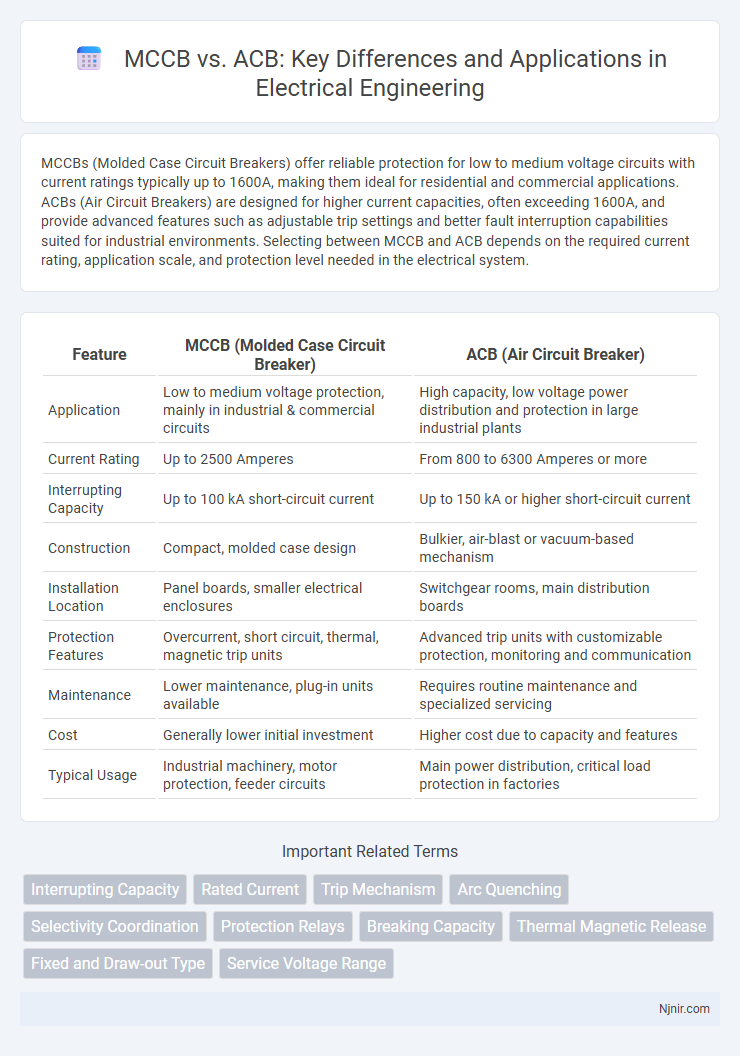

| Feature | MCCB (Molded Case Circuit Breaker) | ACB (Air Circuit Breaker) |

|---|---|---|

| Application | Low to medium voltage protection, mainly in industrial & commercial circuits | High capacity, low voltage power distribution and protection in large industrial plants |

| Current Rating | Up to 2500 Amperes | From 800 to 6300 Amperes or more |

| Interrupting Capacity | Up to 100 kA short-circuit current | Up to 150 kA or higher short-circuit current |

| Construction | Compact, molded case design | Bulkier, air-blast or vacuum-based mechanism |

| Installation Location | Panel boards, smaller electrical enclosures | Switchgear rooms, main distribution boards |

| Protection Features | Overcurrent, short circuit, thermal, magnetic trip units | Advanced trip units with customizable protection, monitoring and communication |

| Maintenance | Lower maintenance, plug-in units available | Requires routine maintenance and specialized servicing |

| Cost | Generally lower initial investment | Higher cost due to capacity and features |

| Typical Usage | Industrial machinery, motor protection, feeder circuits | Main power distribution, critical load protection in factories |

Introduction to MCCB and ACB

MCCB (Molded Case Circuit Breaker) provides reliable protection against overloads, short circuits, and electrical faults in low voltage systems, making it ideal for industrial and commercial applications. ACB (Air Circuit Breaker) is designed for higher current ratings and offers more advanced features such as adjustable trip settings and superior interrupting capacity, typically used in power distribution systems. Both MCCBs and ACBs play crucial roles in electrical safety and load management but differ primarily in capacity, application, and control capabilities.

Construction and Design Differences

Molded Case Circuit Breakers (MCCBs) feature a compact, modular design with a molded insulating frame, suitable for low to medium voltage applications up to 1000V and current ratings typically below 2500A. Air Circuit Breakers (ACBs) have a larger, more robust construction with draw-out or fixed types, designed for high-capacity electrical distribution systems, capable of handling currents above 2500A and providing advanced protection and control features. The MCCB's design emphasizes portability and ease of installation, while ACBs focus on customization, maintenance, and integration into complex power distribution setups.

Operating Principles of MCCB and ACB

Molded Case Circuit Breakers (MCCBs) operate using thermal-magnetic trip units that respond to both overload and short-circuit conditions through bimetallic strips and electromagnetic coils, ensuring precise protection for low to medium current applications. Air Circuit Breakers (ACBs) utilize an air blast or magnetic arc extinguishing system with adjustable trip settings, offering high interrupting capacity and superior control for high current industrial circuits. The key operational difference lies in MCCBs' reliance on compact molded case construction for modularity, while ACBs employ large contact assemblies and advanced arc chutes for rapid arc suppression and enhanced safety.

Current and Voltage Ratings

Molded Case Circuit Breakers (MCCBs) typically offer current ratings ranging from 15 amps up to 2,500 amps, suitable for low to medium voltage applications, while Air Circuit Breakers (ACBs) handle higher current ratings starting around 800 amps and extend beyond 6,000 amps, making them ideal for high-power distribution. MCCBs generally operate at voltages up to 1,000 volts AC, whereas ACBs are designed for voltages up to 1,200 volts and sometimes higher, providing superior performance in industrial power networks. The choice between MCCB and ACB depends on the required interrupting capacity, with MCCBs suited for branch circuit protection and ACBs preferred for main power supply protection in electrical systems.

Applications in Electrical Systems

Molded Case Circuit Breakers (MCCB) are predominantly used in low to medium voltage electrical systems for protecting individual circuits and equipment from overload and short circuits within residential, commercial, and light industrial applications. Air Circuit Breakers (ACB) are designed for high current rating applications such as large industrial plants, power distribution, and electrical substations where advanced protection, control, and isolation of high-capacity electrical systems are required. MCCBs excel in circuit protection with compact design, while ACBs are essential for high-capacity system management due to their capability to handle higher fault currents and offer sophisticated trip settings.

Protection Features and Capabilities

Molded Case Circuit Breakers (MCCBs) provide reliable short circuit and overload protection with adjustable trip settings suited for low to medium voltage applications, typically up to 1,000 amps. Air Circuit Breakers (ACBs) offer enhanced protection features including advanced fault detection, ground fault sensing, and precise adjustable tripping, ideal for higher current ratings beyond 1,000 amps in industrial and commercial power systems. ACBs generally have greater interruption capacity and more sophisticated control options, making them suitable for critical power distribution safety and system coordination.

Installation and Maintenance Considerations

MCCBs (Molded Case Circuit Breakers) are compact and easier to install in smaller electrical panels, requiring less space and simpler wiring systems compared to ACBs (Air Circuit Breakers), which demand more room and sophisticated busbar connections. Maintenance of MCCBs is generally straightforward, involving routine checks and cleaning, while ACBs necessitate periodic detailed inspections, including contact resistance tests and mechanism lubrication due to their complex design. Selecting between MCCB and ACB for installation heavily depends on the system size, load requirements, and maintenance capabilities available on-site.

Cost Comparison and Economic Impact

Molded Case Circuit Breakers (MCCBs) generally have a lower upfront cost compared to Air Circuit Breakers (ACBs), making them more suitable for budget-sensitive applications. However, ACBs offer advanced features such as adjustable trip settings and higher interrupting capacities, which can reduce maintenance and replacement costs over time, yielding better long-term economic benefits. The total cost of ownership favors MCCBs for smaller-scale installations, while ACBs provide superior value in large industrial setups due to their scalability and enhanced protection capabilities.

Selection Criteria for MCCB vs ACB

Selection criteria for MCCB versus ACB primarily depend on the application's current rating, breaking capacity, and operational frequency. MCCBs are ideal for low to medium voltage circuits with current ratings typically up to 1000A and short circuit breaking capacities around 50kA, making them suitable for residential or small industrial installations. In contrast, ACBs support higher current ratings above 1000A with breaking capacities exceeding 100kA, often used in large commercial or industrial power distribution systems requiring frequent switching and enhanced protection features.

Future Trends and Technological Advancements

Molded Case Circuit Breakers (MCCBs) and Air Circuit Breakers (ACBs) are evolving with advancements in smart grid integration and IoT-enabled monitoring capabilities, enhancing predictive maintenance and real-time fault detection. Future trends emphasize AI-driven analytics and digital twin technology to improve operational efficiency and reduce downtime in both MCCBs and ACBs. The development of eco-friendly insulation materials and compact, modular designs further supports sustainability and scalability in industrial electrical protection systems.

Interrupting Capacity

MCCBs typically have interrupting capacities ranging from 10 kA to 100 kA, while ACBs offer higher interrupting capacities up to 150 kA or more, making ACBs more suitable for industrial applications with higher fault current requirements.

Rated Current

MCCBs typically have rated currents up to 1600A, whereas ACBs are designed for higher rated currents exceeding 1600A, often up to 8000A or more.

Trip Mechanism

MCCB trip mechanisms rely on thermal-magnetic triggers for overload and short circuit protection, while ACB trip mechanisms use advanced electronic sensors and microprocessor-based relays for precise fault detection and coordination.

Arc Quenching

MCCB provides arc quenching through magnetic blowouts for low to medium fault currents, while ACB uses advanced air-blast or vacuum arc quenching mechanisms suitable for higher fault current ratings and faster interruption.

Selectivity Coordination

MCCB offers limited selectivity coordination suitable for low to medium voltage applications, whereas ACB provides superior selectivity coordination capabilities for high current, high voltage systems ensuring enhanced protection and operational reliability.

Protection Relays

MCCBs provide basic overload and short circuit protection suitable for low-voltage applications, while ACBs integrate advanced protection relays offering comprehensive fault detection, including earth leakage, under-voltage, and communication capabilities for enhanced electrical system safety.

Breaking Capacity

MCCBs typically have breaking capacities ranging from 10kA to 100kA, while ACBs offer higher breaking capacities up to 150kA or more, making ACBs suitable for high-current industrial applications requiring superior fault interruption performance.

Thermal Magnetic Release

Thermal magnetic release in MCCBs provides dual protection by combining thermal overload sensing with magnetic short-circuit interruption, while ACBs primarily use magnetic release mechanisms for rapid short-circuit protection in high-capacity applications.

Fixed and Draw-out Type

Fixed type MCCBs are permanently installed breakers offering compact size and easy maintenance, while draw-out type ACBs provide withdrawable mechanisms enabling quick replacement and advanced protection in high-current applications.

Service Voltage Range

MCCBs typically operate within a service voltage range of 240V to 600V, whereas ACBs are designed for higher service voltage ranges, often from 240V up to 690V or more.

MCCB vs ACB Infographic

njnir.com

njnir.com