DQO (Data Quality Objectives) ensures accurate and reliable data collection essential for effective SCADA (Supervisory Control and Data Acquisition) system performance in electrical engineering. SCADA processes real-time data for monitoring and control of electrical grids, relying heavily on strict DQO to minimize errors and enhance system responsiveness. Optimizing DQO enhances decision-making accuracy, leading to improved operational efficiency and reduced downtime in electrical infrastructure management.

Table of Comparison

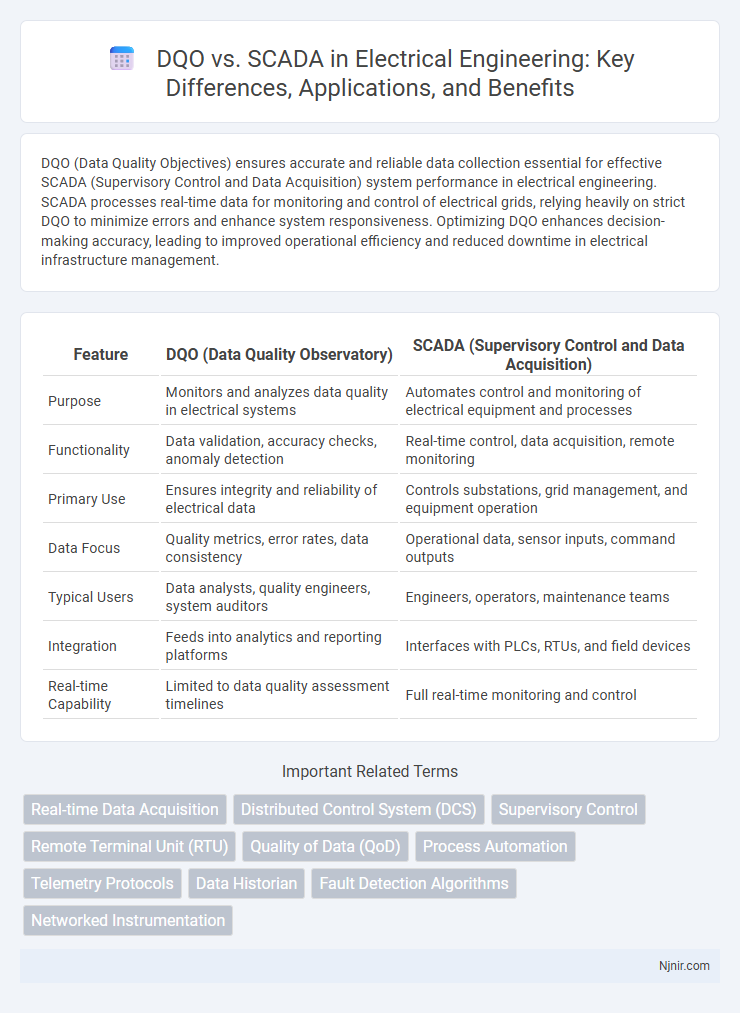

| Feature | DQO (Data Quality Observatory) | SCADA (Supervisory Control and Data Acquisition) |

|---|---|---|

| Purpose | Monitors and analyzes data quality in electrical systems | Automates control and monitoring of electrical equipment and processes |

| Functionality | Data validation, accuracy checks, anomaly detection | Real-time control, data acquisition, remote monitoring |

| Primary Use | Ensures integrity and reliability of electrical data | Controls substations, grid management, and equipment operation |

| Data Focus | Quality metrics, error rates, data consistency | Operational data, sensor inputs, command outputs |

| Typical Users | Data analysts, quality engineers, system auditors | Engineers, operators, maintenance teams |

| Integration | Feeds into analytics and reporting platforms | Interfaces with PLCs, RTUs, and field devices |

| Real-time Capability | Limited to data quality assessment timelines | Full real-time monitoring and control |

Introduction to DQO and SCADA in Electrical Engineering

DQO (Data Quality Objectives) in electrical engineering define the precision, accuracy, and reliability needed for data collection in system monitoring and analysis. SCADA (Supervisory Control and Data Acquisition) systems are essential for real-time monitoring, control, and data acquisition of electrical grids and substations. Together, DQO ensures SCADA data meets the required quality standards for effective decision-making and operational efficiency.

Fundamental Concepts: Defining DQO and SCADA

Data Quality Objectives (DQO) establish the criteria and levels of data accuracy, precision, and reliability necessary to support decision-making processes in environmental monitoring and analysis. Supervisory Control and Data Acquisition (SCADA) systems are industrial control systems that gather real-time data from sensors and equipment to monitor, control, and automate infrastructure operations. While DQO focuses on ensuring data meets predefined quality standards, SCADA emphasizes real-time data acquisition and operational management in industrial environments.

Core Functions of DQO Systems

DQO systems primarily focus on data quality objectives by ensuring accurate, consistent, and reliable data collection and validation across industrial processes. Unlike SCADA, which emphasizes real-time monitoring and control of equipment and operations, DQO systems specialize in data integrity management, including data cleansing, validation rules, and error detection. This core functionality supports informed decision-making and regulatory compliance by delivering high-quality datasets for analysis and reporting.

Key Features of SCADA Systems

SCADA systems are designed to provide real-time data acquisition, monitoring, and control across industrial processes, featuring centralized data collection and advanced visualization tools. They offer alarm management, historical data logging, and remote access capabilities, which enable operators to respond quickly to system anomalies. These key features distinguish SCADA from DQO systems, which primarily focus on data quality objectives rather than process control.

Comparative Analysis: DQO vs SCADA

DQO (Data Quality Objective) and SCADA (Supervisory Control and Data Acquisition) serve distinct roles in industrial automation, where DQO focuses on setting criteria to ensure accuracy and reliability of data collected, while SCADA provides real-time monitoring and control of industrial processes. DQO's emphasis lies in defining data quality standards to validate data integrity, whereas SCADA systems integrate hardware and software to visualize and respond to process conditions dynamically. Comparing these, DQO ensures the trustworthiness of data input for decision-making, while SCADA offers operational control and system oversight based on that data.

Applications of DQO in Electrical Networks

DQO systems in electrical networks optimize data quality by continuously monitoring and validating sensor inputs, ensuring accurate energy flow measurements and fault detection. These applications enhance grid reliability and support real-time decision-making for load balancing and outage management. Integrating DQO with SCADA platforms improves overall system performance by providing cleaner data streams for control and automation processes.

SCADA Applications in Power Systems

SCADA systems in power systems enable real-time monitoring, control, and automation of electrical grids, improving reliability and efficiency. They facilitate data acquisition from substations, transformer stations, and distribution networks to optimize load management and fault detection. Integration of SCADA with smart grid technologies enhances predictive maintenance and supports demand response strategies.

Integration of DQO with SCADA Technologies

The integration of Data Quality Optimization (DQO) with Supervisory Control and Data Acquisition (SCADA) systems enhances real-time monitoring and control by ensuring accurate and reliable data flows across industrial processes. Leveraging advanced analytics and machine learning, DQO improves data validation and anomaly detection within SCADA architectures, leading to optimized operational efficiency and predictive maintenance. Seamless interoperability between DQO platforms and SCADA technologies facilitates centralized data management and drives smarter decision-making in complex automation environments.

Advantages and Limitations of DQO and SCADA

Data Quality Objectives (DQO) provide a structured framework for defining the quality and usability requirements of environmental data, ensuring accuracy and reliability essential for decision-making but may require significant time and expertise to develop effectively. Supervisory Control and Data Acquisition (SCADA) systems offer real-time monitoring and control of industrial processes, enhancing operational efficiency and rapid response, yet they can be costly to implement and vulnerable to cybersecurity threats. While DQOs emphasize data integrity and validation protocols, SCADA prioritizes seamless automation and system integration, making their combined use beneficial but necessitating careful consideration of respective limitations.

Future Trends in DQO and SCADA for Electrical Engineering

Future trends in DQO (Data Quality Optimization) and SCADA (Supervisory Control and Data Acquisition) for electrical engineering emphasize enhanced integration of AI-driven analytics and real-time data processing to improve system reliability and predictive maintenance. Advances in IoT connectivity and edge computing are enabling more efficient data collection and local decision-making, reducing latency and enhancing operational efficiency. Cybersecurity improvements are also critical, with adaptive threat detection systems being developed to protect critical infrastructure from evolving cyber-attacks.

Real-time Data Acquisition

SCADA systems provide comprehensive real-time data acquisition and process control, while DQO tools specialize in ensuring data quality and accuracy during real-time data collection.

Distributed Control System (DCS)

Distributed Control Systems (DCS) offer more scalable, reliable, and integrated process control solutions compared to SCADA, while Data Quality Objectives (DQO) primarily guide data accuracy and integrity in control environments.

Supervisory Control

Supervisory Control in SCADA systems enables real-time monitoring and automation of industrial processes, whereas DQO primarily focuses on data quality optimization without direct control capabilities.

Remote Terminal Unit (RTU)

Remote Terminal Units (RTUs) in SCADA systems enable real-time data acquisition and control, while DQO primarily emphasizes data quality optimization without direct hardware integration.

Quality of Data (QoD)

DQO enhances Quality of Data (QoD) by rigorously validating and cleansing sensor inputs before integration into SCADA systems, ensuring higher accuracy and reliability in real-time monitoring and decision-making processes.

Process Automation

DQO systems enhance process automation by providing advanced data quality optimization and real-time analytics, while SCADA focuses on supervisory control and monitoring of industrial processes.

Telemetry Protocols

DQO utilizes specialized telemetry protocols optimized for data quality and accuracy, whereas SCADA employs standardized telemetry protocols designed for real-time monitoring and control across diverse industrial systems.

Data Historian

Data Historian systems in SCADA environments enable real-time data collection, storage, and analysis, while DQO solutions prioritize data quality optimization for accurate and reliable data management.

Fault Detection Algorithms

Fault Detection Algorithms in SCADA systems enable real-time monitoring and rapid identification of operational anomalies, whereas DQO primarily focuses on data quality optimization without integrated fault detection capabilities.

Networked Instrumentation

Networked instrumentation in DQO systems enables real-time data acquisition and precise quality control, whereas SCADA focuses on centralized monitoring and control of industrial processes over distributed networks.

DQO vs SCADA Infographic

njnir.com

njnir.com