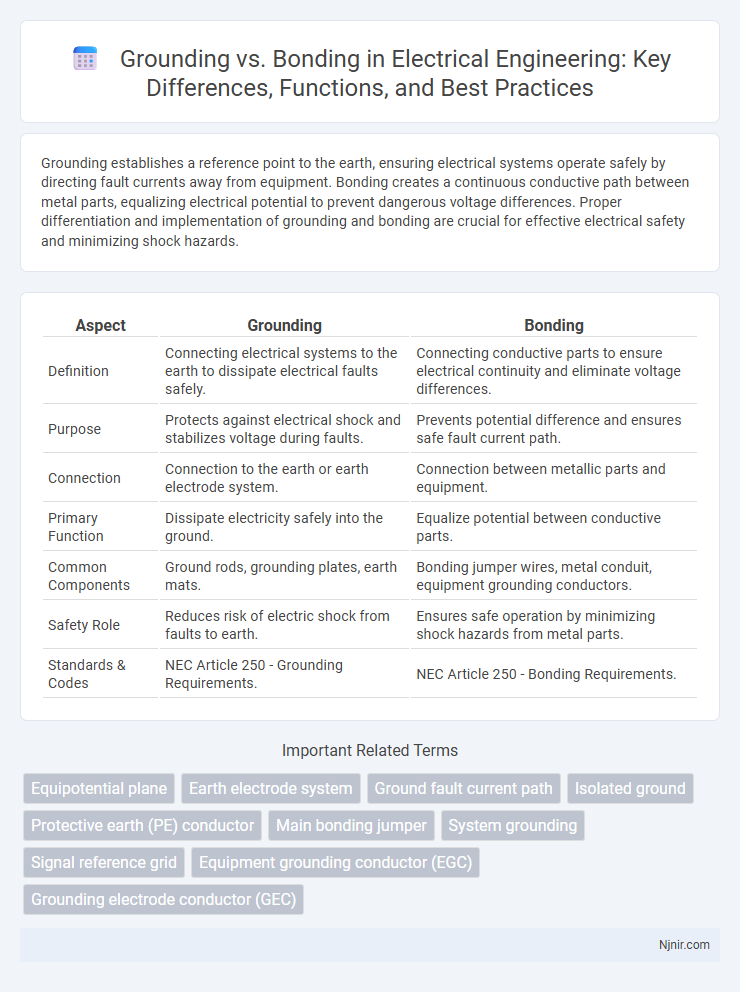

Grounding establishes a reference point to the earth, ensuring electrical systems operate safely by directing fault currents away from equipment. Bonding creates a continuous conductive path between metal parts, equalizing electrical potential to prevent dangerous voltage differences. Proper differentiation and implementation of grounding and bonding are crucial for effective electrical safety and minimizing shock hazards.

Table of Comparison

| Aspect | Grounding | Bonding |

|---|---|---|

| Definition | Connecting electrical systems to the earth to dissipate electrical faults safely. | Connecting conductive parts to ensure electrical continuity and eliminate voltage differences. |

| Purpose | Protects against electrical shock and stabilizes voltage during faults. | Prevents potential difference and ensures safe fault current path. |

| Connection | Connection to the earth or earth electrode system. | Connection between metallic parts and equipment. |

| Primary Function | Dissipate electricity safely into the ground. | Equalize potential between conductive parts. |

| Common Components | Ground rods, grounding plates, earth mats. | Bonding jumper wires, metal conduit, equipment grounding conductors. |

| Safety Role | Reduces risk of electric shock from faults to earth. | Ensures safe operation by minimizing shock hazards from metal parts. |

| Standards & Codes | NEC Article 250 - Grounding Requirements. | NEC Article 250 - Bonding Requirements. |

Introduction to Grounding and Bonding

Grounding refers to the process of connecting electrical systems to the earth to ensure safety by dissipating fault current and preventing electric shock. Bonding involves creating an electrically conductive path between metal parts to maintain a common electrical potential, reducing the risk of dangerous voltage differences. Together, grounding and bonding are essential for protecting people and equipment in electrical installations by minimizing electrical hazards and improving system reliability.

Fundamental Concepts of Grounding

Grounding involves creating a direct physical connection to the earth to stabilize electrical voltage and protect against electrical faults. It ensures safety by providing a path for fault currents to dissipate into the ground, reducing the risk of electric shock and equipment damage. Key concepts include earth electrodes, grounding conductors, and maintaining low impedance paths to facilitate effective fault current flow.

Essential Principles of Bonding

Bonding involves creating a low-resistance path connecting all metallic components and electrical systems to ensure safety and prevent voltage differences, essential for effective fault current dissipation. It relies on the principle that all bonded parts share the same electrical potential, minimizing the risk of electric shock and equipment damage. Proper bonding ensures reliable operation of overcurrent protection devices by facilitating immediate fault current flow to the ground system.

Key Differences Between Grounding and Bonding

Grounding involves connecting electrical systems to the earth to dissipate excess voltage and protect against electrical faults, whereas bonding creates a continuous electrical path between metal components to ensure equal voltage and prevent potential differences. Grounding primarily safeguards against electrical surges by directing fault current into the earth, while bonding focuses on minimizing shock hazards by maintaining electrical continuity across conductive parts. Understanding these distinctions is crucial for effective electrical safety and compliance with National Electrical Code (NEC) requirements.

Purpose and Importance in Electrical Systems

Grounding establishes a reference point in electrical systems, ensuring safety by preventing electric shock and equipment damage through directing fault currents safely into the earth. Bonding creates an equipotential path by connecting all conductive parts together, minimizing voltage differences and reducing the risk of electrical hazards. Both grounding and bonding work synergistically to enhance system reliability, protect people, and maintain operational integrity in residential, commercial, and industrial installations.

Grounding Methods and Techniques

Grounding methods in electrical systems involve connecting equipment and circuits directly to the earth to ensure safety and prevent electric shocks. Common techniques include driven rods, ground plates, and ground rings, which provide low-resistance paths to dissipate fault currents. Proper grounding enhances system stability and protects sensitive electronics by minimizing voltage fluctuations and electrical noise.

Bonding Practices and Standards

Bonding practices and standards are critical in electrical systems to ensure safety by creating a low-resistance path that facilitates fault current flow, preventing electric shock and equipment damage. Standards such as the NEC (National Electrical Code) in the United States and IEC (International Electrotechnical Commission) guidelines define requirements for bonding conductors, connections, and bonding jumpers to maintain system integrity and reduce potential differences across conductive parts. Effective bonding involves connecting metal parts like enclosures, raceways, and structural steel to the grounding system, ensuring electrical continuity and consistent system potential.

Common Applications in Residential and Industrial Settings

Grounding and bonding serve critical roles in electrical systems; grounding connects electrical circuits to the earth to prevent shock hazards, while bonding ensures all metallic parts are electrically connected to maintain continuity and eliminate voltage differences. In residential settings, grounding commonly involves grounding rods and grounding wires to protect household occupants from electrical faults, whereas bonding links metal pipes, panels, and fixtures to reduce fire risks and improve safety. Industrial applications prioritize extensive grounding grids and robust bonding practices to safeguard complex machinery, prevent static discharge, and ensure compliance with safety standards.

Safety Risks of Improper Grounding and Bonding

Improper grounding and bonding in electrical systems significantly increase safety risks, including electrical shock, equipment damage, and fire hazards. Grounding failures can cause stray voltages that pose severe injury risks, while inadequate bonding can prevent proper fault current flow, leading to overheating and arc faults. Ensuring code-compliant grounding and bonding is critical to minimizing electrocution risks and maintaining system stability.

Compliance with Electrical Codes and Regulations

Grounding and bonding are critical for compliance with electrical codes such as the NEC (National Electrical Code) to ensure safety and prevent electrical hazards. Grounding provides a path for electrical current to dissipate safely into the earth, reducing shock risk, while bonding maintains electrical continuity and ensures all metal parts are at the same potential to prevent voltage differences. Proper installation adhering to standards like NFPA 70 guarantees effective grounding and bonding, essential for code compliance and equipment protection.

Equipotential plane

The equipotential plane in grounding vs bonding systems ensures uniform voltage distribution, minimizing electric shock hazards and improving electrical safety in installations.

Earth electrode system

The Earth electrode system in grounding provides a low-resistance path for fault currents to safely dissipate into the earth, while bonding ensures all metallic parts are electrically connected to maintain equipotential and prevent voltage differences.

Ground fault current path

Grounding establishes a safe ground fault current path by connecting electrical systems to the earth to prevent shock hazards, while bonding ensures conductive parts are electrically connected to maintain equal potential and facilitate fault current return.

Isolated ground

Isolated ground systems reduce electrical noise and prevent ground loops by providing a dedicated grounding path separate from building grounds, enhancing signal integrity in sensitive electronic equipment.

Protective earth (PE) conductor

The Protective Earth (PE) conductor in grounding provides a low-resistance path for fault currents to enhance safety, while bonding ensures electrical continuity and equal potential between conductive parts to prevent electric shock hazards.

Main bonding jumper

The main bonding jumper ensures electrical continuity and proper grounding by connecting the equipment grounding conductor to the grounding electrode system, preventing electrical shock hazards and ensuring system safety.

System grounding

System grounding ensures electrical safety and equipment protection by connecting electrical systems to the earth, preventing voltage surges and reducing the risk of electric shock.

Signal reference grid

Grounding establishes a stable signal reference grid by connecting electrical systems to the earth, while bonding ensures low-resistance connections between metallic parts to maintain signal integrity and prevent potential differences.

Equipment grounding conductor (EGC)

The Equipment Grounding Conductor (EGC) provides a safe path for fault current to prevent electrical shock by connecting non-current-carrying metal parts to the grounding system, distinguishing grounding from bonding which ensures electrical continuity and potential equalization between conductive parts.

Grounding electrode conductor (GEC)

The Grounding Electrode Conductor (GEC) connects the electrical system to the earth, providing a low-resistance path to dissipate fault currents and stabilize voltage levels, distinguishing it from bonding which primarily ensures electrical continuity between metallic parts.

Grounding vs Bonding Infographic

njnir.com

njnir.com