Pulse Width Modulation (PWM) offers precise control of average power delivery by varying the duty cycle, making it ideal for applications requiring consistent voltage levels and minimal electromagnetic interference. Pulse Frequency Modulation (PFM) adjusts the switching frequency to regulate power, enhancing efficiency at light loads but potentially causing higher output noise and ripple. Selecting between PWM and PFM depends on the balance between power efficiency, noise tolerance, and load conditions in electrical engineering designs.

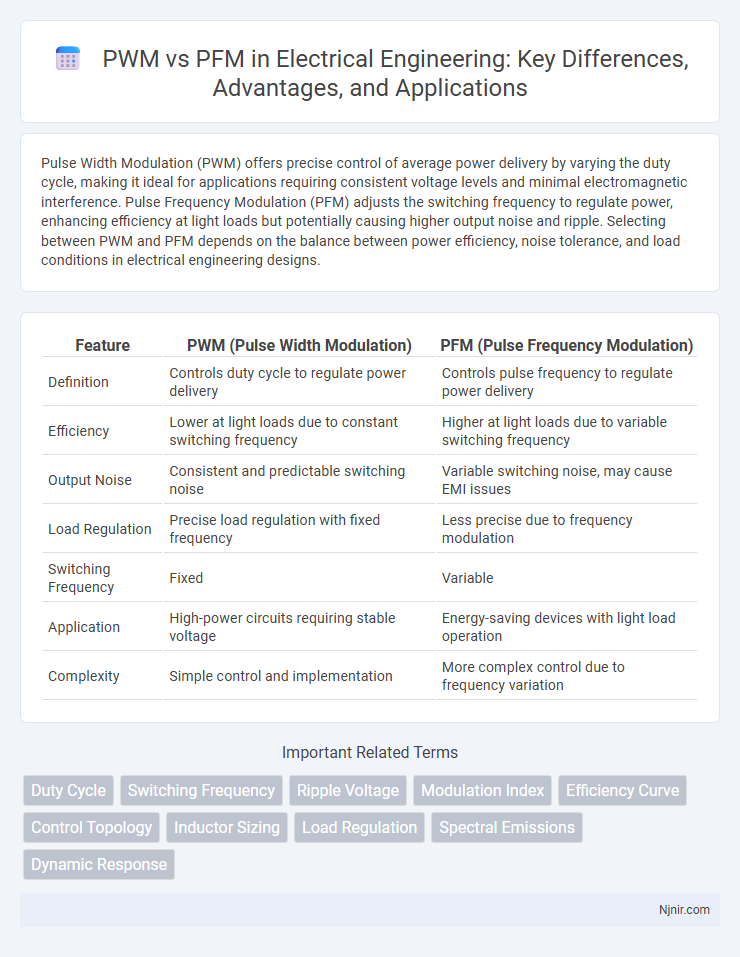

Table of Comparison

| Feature | PWM (Pulse Width Modulation) | PFM (Pulse Frequency Modulation) |

|---|---|---|

| Definition | Controls duty cycle to regulate power delivery | Controls pulse frequency to regulate power delivery |

| Efficiency | Lower at light loads due to constant switching frequency | Higher at light loads due to variable switching frequency |

| Output Noise | Consistent and predictable switching noise | Variable switching noise, may cause EMI issues |

| Load Regulation | Precise load regulation with fixed frequency | Less precise due to frequency modulation |

| Switching Frequency | Fixed | Variable |

| Application | High-power circuits requiring stable voltage | Energy-saving devices with light load operation |

| Complexity | Simple control and implementation | More complex control due to frequency variation |

Introduction to PWM and PFM

Pulse Width Modulation (PWM) controls power delivery by varying the duty cycle of a fixed-frequency signal, making it ideal for applications requiring precise voltage regulation and efficient energy use. Pulse Frequency Modulation (PFM) adjusts the frequency of pulses while maintaining a constant pulse width, optimizing performance for light-load conditions by reducing switching losses. Both techniques are widely used in power electronics to balance efficiency and performance across varying load demands.

Fundamental Principles of PWM

Pulse Width Modulation (PWM) operates by varying the duty cycle of a fixed-frequency waveform to control the average power delivered to a load, enabling precise regulation of voltage and current. By adjusting the on-time relative to the off-time within each cycle, PWM maintains a consistent switching frequency that reduces electromagnetic interference and improves efficiency. This modulation technique is essential in applications such as motor control, LED dimming, and power supplies, where stable and efficient energy delivery is critical.

Core Concepts of PFM

Pulse Frequency Modulation (PFM) adjusts the switching frequency based on the load, optimizing energy efficiency by varying the pulse repetition rate while maintaining consistent pulse width. Unlike Pulse Width Modulation (PWM), which keeps frequency constant and changes duty cycle, PFM reduces switching losses and improves performance under light load conditions. Key concepts of PFM include dynamic frequency scaling, load-dependent switching, and enhanced power savings in low-power and battery-operated applications.

PWM vs PFM: Operational Differences

PWM (Pulse Width Modulation) controls output by varying the pulse width while maintaining a constant frequency, resulting in precise voltage regulation and efficient power delivery. PFM (Pulse Frequency Modulation) adjusts the frequency of pulses with a constant pulse width to improve efficiency at light loads by reducing switching losses. PWM provides better noise immunity and stability during high-load conditions, whereas PFM excels in low-power scenarios by minimizing switching activity.

Efficiency Comparison in Power Conversion

PWM (Pulse Width Modulation) and PFM (Pulse Frequency Modulation) differ significantly in efficiency during power conversion, with PWM maintaining consistent switching frequency that optimizes performance at higher loads. PFM adjusts switching frequency according to load demand, offering superior efficiency at light loads by reducing switching losses. Efficiency in PWM dominates during heavy load conditions due to stable operation, while PFM excels in low-power scenarios by minimizing energy wastage.

Application Areas: Where PWM Shines

PWM (Pulse Width Modulation) excels in applications requiring precise control of power delivery, such as motor speed regulation in electric vehicles and industrial automation. Its ability to provide consistent output voltage and efficient energy use makes it ideal for LED dimming, power supplies, and audio amplifiers. PWM is favored in systems demanding low electromagnetic interference and high switching frequency performance.

PFM Advantages in Low-Power Designs

PFM (Pulse Frequency Modulation) offers significant advantages in low-power designs by reducing switching losses and increasing efficiency at light loads compared to PWM (Pulse Width Modulation). PFM adjusts the frequency of pulses based on load demand, allowing circuits to consume less power and extend battery life in portable devices. This modulation technique is particularly effective in applications requiring minimal quiescent current and prolonged operational time.

Impact on Electromagnetic Interference (EMI)

PWM generates consistent switching frequencies that can create predictable EMI patterns, requiring careful filtering and shielding to mitigate interference. PFM operates with variable frequencies and pulse widths, often reducing EMI emissions by spreading the noise spectrum and lowering peak interference levels. Designers must select the modulation technique based on EMI sensitivity, with PFM preferred in noise-critical applications and PWM favored for efficiency and control precision.

Design Considerations for Engineers

PWM (Pulse Width Modulation) offers precise control of output voltage by varying duty cycle, making it ideal for applications requiring stable frequency and consistent power delivery. PFM (Pulse Frequency Modulation) adjusts the switching frequency to maintain efficiency at light loads, reducing power consumption and improving battery life in portable devices. Engineers must weigh the trade-offs between PWM's low noise and PFM's higher efficiency for design optimization in power management systems.

Choosing Between PWM and PFM for Your Project

Choosing between PWM (Pulse Width Modulation) and PFM (Pulse Frequency Modulation) depends on your project's efficiency and noise requirements. PWM offers precise voltage control and is ideal for applications needing high efficiency at steady loads, such as motor control and LED dimming. PFM suits low-power applications with variable loads by reducing switching frequency and minimizing electromagnetic interference (EMI), making it optimal for battery-powered devices.

Duty Cycle

PWM controls power by varying the fixed-frequency duty cycle, while PFM adjusts the pulse frequency with typically full or zero duty cycle to regulate energy delivery.

Switching Frequency

PWM maintains a fixed switching frequency for stable output voltage, while PFM varies switching frequency based on load to optimize efficiency.

Ripple Voltage

PWM achieves lower ripple voltage compared to PFM by maintaining a constant switching frequency and duty cycle, resulting in more stable output voltage regulation.

Modulation Index

Pulse Width Modulation (PWM) achieves a higher modulation index with precise duty cycle control, while Pulse Frequency Modulation (PFM) varies pulse frequency resulting in a lower and less stable modulation index.

Efficiency Curve

PWM typically delivers higher efficiency at steady loads with a flatter efficiency curve, while PFM excels in light-load conditions by maintaining better efficiency through variable frequency control.

Control Topology

Pulse Width Modulation (PWM) control topology adjusts output voltage by varying pulse width with fixed frequency, while Pulse Frequency Modulation (PFM) modifies output by changing pulse frequency at a constant pulse width for enhanced efficiency in light-load conditions.

Inductor Sizing

PWM requires larger inductors to maintain steady current, while PFM allows smaller inductors due to variable pulse width and reduced switching frequency.

Load Regulation

PWM provides superior load regulation by maintaining a constant switching frequency and duty cycle, ensuring stable output voltage under varying load conditions compared to PFM.

Spectral Emissions

PWM modulation generates discrete spectral emissions with strong harmonics at switching frequencies, while PFM modulation produces wider, less predictable spectral noise distribution, reducing electromagnetic interference in sensitive applications.

Dynamic Response

PWM offers faster dynamic response and better output voltage regulation under transient load conditions compared to PFM, which prioritizes efficiency but exhibits slower response times.

PWM vs PFM Infographic

njnir.com

njnir.com