No-load losses occur in electrical machines due to core magnetization and hysteresis even when no load is applied, primarily affecting efficiency during idle operation. Load losses arise from resistive heating and stray losses within the windings and components when current flows under load conditions, increasing with the load magnitude. Minimizing both no-load and load losses is essential for optimizing energy efficiency and reducing operational costs in electrical systems.

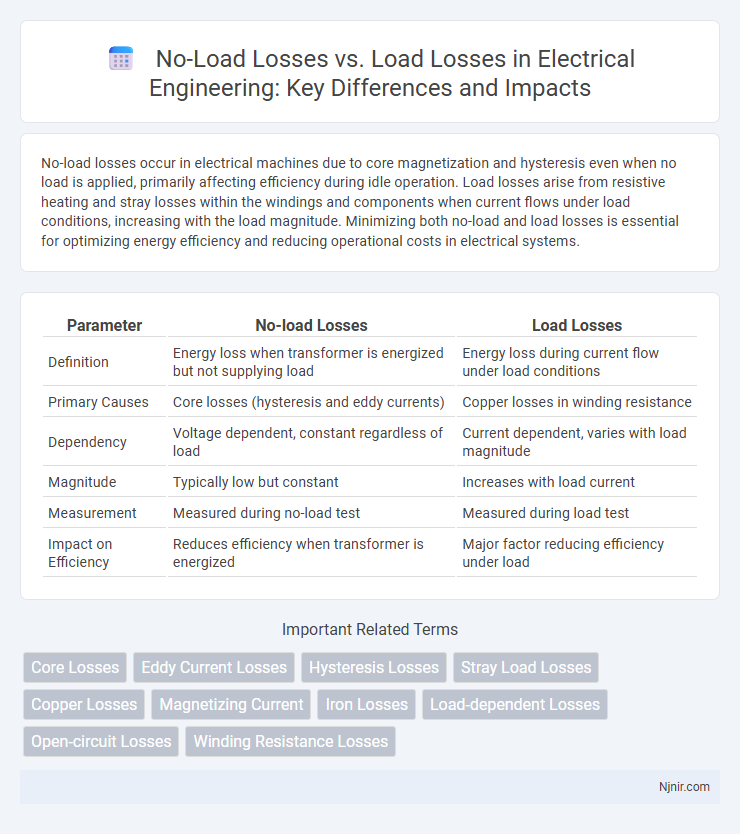

Table of Comparison

| Parameter | No-load Losses | Load Losses |

|---|---|---|

| Definition | Energy loss when transformer is energized but not supplying load | Energy loss during current flow under load conditions |

| Primary Causes | Core losses (hysteresis and eddy currents) | Copper losses in winding resistance |

| Dependency | Voltage dependent, constant regardless of load | Current dependent, varies with load magnitude |

| Magnitude | Typically low but constant | Increases with load current |

| Measurement | Measured during no-load test | Measured during load test |

| Impact on Efficiency | Reduces efficiency when transformer is energized | Major factor reducing efficiency under load |

Introduction to No-load Losses and Load Losses

No-load losses occur in electrical transformers when the device is energized but not supplying load, primarily caused by core hysteresis and eddy current effects in the magnetic core. Load losses, also known as copper losses, arise from the resistance in the transformer windings when current flows during operation, increasing with the load magnitude. Understanding the distinction between no-load and load losses is essential for optimizing transformer efficiency and reducing energy waste in power distribution systems.

Definitions and Key Differences

No-load losses occur in electrical transformers when the transformer is energized but not supplying any load current, primarily caused by core magnetization and hysteresis effects; these losses remain constant regardless of load conditions. Load losses, also known as copper losses, arise from the resistance in the transformer windings and increase proportionally with the current flowing through the load, resulting in heat dissipation during active power transfer. The key difference lies in the dependency on load current, as no-load losses are fixed and present whenever the transformer is energized, while load losses vary directly with the magnitude of the load current.

Sources of No-load Losses in Electrical Equipment

No-load losses in electrical equipment primarily originate from core losses such as hysteresis and eddy currents occurring in the transformer or motor core materials. These losses persist regardless of the electrical load and are influenced by factors like magnetic flux density and frequency. Understanding the sources of no-load losses is crucial for improving energy efficiency and minimizing unnecessary power dissipation during idle operation.

Origins of Load Losses in Electrical Systems

Load losses in electrical systems primarily originate from the resistance in conductors and transformers during current flow, causing I2R (current squared times resistance) losses that increase with load. These losses also stem from eddy currents and hysteresis within transformer cores, which intensify under higher load conditions. Understanding and minimizing load losses is crucial for enhancing energy efficiency and reducing operational costs in power distribution networks.

Impact of No-load and Load Losses on Efficiency

No-load losses, primarily caused by core magnetization and eddy currents, occur regardless of electrical load and consistently reduce transformer efficiency by generating constant energy dissipation. Load losses, including copper losses in windings, increase proportionally with the square of the load current, significantly affecting efficiency during high-demand periods. Minimizing both no-load and load losses is crucial for optimizing overall transformer efficiency and reducing operational costs in power systems.

Methods for Measuring No-load and Load Losses

No-load losses are typically measured using a wattmeter during open-circuit test conditions where the transformer is energized without load, allowing the assessment of core losses such as hysteresis and eddy currents. Load losses are determined through a short-circuit test by applying a reduced voltage to the transformer while energized under full-load current conditions, isolating winding resistance and leakage reactance effects. Both methods ensure accurate quantification of transformer efficiency by separating core and copper losses.

Reduction Techniques for No-load Losses

No-load losses, primarily caused by hysteresis and eddy currents in transformer cores, can be significantly reduced through the use of high-quality silicon steel laminations with optimized thickness to minimize eddy currents. Grain-oriented electrical steel and improved core design, such as adopting a strip winding technique and interleaving laminations, further enhance magnetic properties and reduce core excitations responsible for no-load losses. Implementing advanced annealing processes and ensuring tight assembly tolerances also contribute to lowering no-load losses while maintaining transformer efficiency during idle conditions.

Minimizing Load Losses in Electrical Networks

Minimizing load losses in electrical networks is crucial for enhancing overall system efficiency and reliability. Load losses, primarily caused by the resistance in conductors under operating current, directly impact energy consumption and operational costs. Employing higher-conductivity materials, optimizing conductor sizes, and utilizing advanced network configurations significantly reduce these losses, leading to improved power delivery and reduced carbon emissions.

Practical Applications and Case Studies

No-load losses, primarily caused by core hysteresis and eddy currents in transformers, remain constant regardless of the load and significantly impact energy efficiency during low or no-load conditions, making them critical in applications with prolonged idle periods such as grid substations. Load losses, which increase with current flow due to winding resistance and stray losses, dominate in heavily loaded systems and are essential considerations in industrial plants where equipment operates near full capacity. Case studies in power distribution networks highlight that optimizing transformer design and load management strategies tailored to specific operating profiles can reduce total energy losses by up to 15%, demonstrating the practical value of balancing no-load and load loss mitigation.

Future Trends in Loss Reduction Technologies

No-load losses, primarily caused by core hysteresis and eddy currents, are being reduced through advanced materials like amorphous steel and nanocrystalline alloys that minimize magnetic energy dissipation. Load losses, stemming from conductor resistance and stray losses, are decreasing due to innovations in high-temperature superconductors and optimized conductor designs that enhance current-carrying efficiency. Future trends emphasize integrating smart sensors and AI-driven monitoring systems to dynamically adjust operating conditions, further minimizing both no-load and load losses in power distribution networks.

Core Losses

Core losses, also known as no-load losses, occur due to the magnetizing current in transformers and remain constant regardless of the load, whereas load losses increase with the load current and result primarily from winding resistance.

Eddy Current Losses

Eddy current losses, a significant component of no-load losses in transformers, occur due to induced currents in the core caused by alternating magnetic fields, while load losses primarily arise from resistance in the windings under operational load.

Hysteresis Losses

Hysteresis losses, a primary component of no-load losses in transformers, occur due to the continuous magnetization and demagnetization of the core material as the magnetic flux changes during operation, causing energy dissipation even without load current.

Stray Load Losses

Stray load losses, a component of load losses in electrical transformers, occur due to leakage flux causing eddy currents in structural parts and increase with load, unlike no-load losses which remain constant regardless of load.

Copper Losses

Copper losses, a key component of load losses, increase with current flow in transformers, while no-load losses remain constant regardless of load.

Magnetizing Current

Magnetizing current primarily causes no-load losses in transformers by inducing core hysteresis and eddy current losses even when the transformer is not supplying load.

Iron Losses

Iron losses, also known as no-load losses, occur in the transformer's core due to hysteresis and eddy currents and remain constant regardless of load, whereas load losses increase with the current flow in the windings.

Load-dependent Losses

Load-dependent losses in electrical systems increase proportionally with the current flowing through the load, impacting energy efficiency and operational costs significantly more than no-load losses.

Open-circuit Losses

Open-circuit losses, a subset of no-load losses in transformers, primarily result from core hysteresis and eddy currents occurring when the transformer is energized without load, differing fundamentally from load losses that arise from resistive heating under load conditions.

Winding Resistance Losses

Winding resistance losses, a major component of load losses, increase proportionally with current, whereas no-load losses remain constant regardless of load.

No-load Losses vs Load Losses Infographic

njnir.com

njnir.com