Isolated DC-DC converters provide galvanic isolation between input and output, enhancing safety and reducing noise interference, which is essential in sensitive electrical engineering applications. Non-isolated DC-DC converters, while more compact and efficient due to the lack of isolation components, are suited for applications where isolation is not required and cost or size constraints are critical. Choosing between isolated and non-isolated converters depends on factors such as voltage level, safety requirements, electromagnetic interference, and application-specific needs.

Table of Comparison

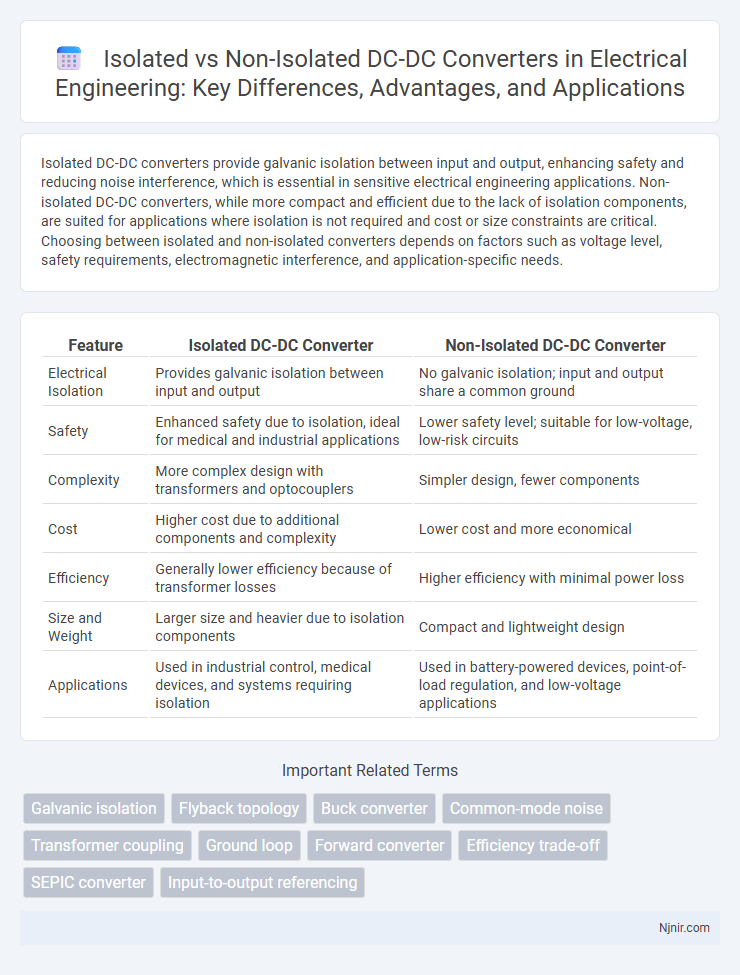

| Feature | Isolated DC-DC Converter | Non-Isolated DC-DC Converter |

|---|---|---|

| Electrical Isolation | Provides galvanic isolation between input and output | No galvanic isolation; input and output share a common ground |

| Safety | Enhanced safety due to isolation, ideal for medical and industrial applications | Lower safety level; suitable for low-voltage, low-risk circuits |

| Complexity | More complex design with transformers and optocouplers | Simpler design, fewer components |

| Cost | Higher cost due to additional components and complexity | Lower cost and more economical |

| Efficiency | Generally lower efficiency because of transformer losses | Higher efficiency with minimal power loss |

| Size and Weight | Larger size and heavier due to isolation components | Compact and lightweight design |

| Applications | Used in industrial control, medical devices, and systems requiring isolation | Used in battery-powered devices, point-of-load regulation, and low-voltage applications |

Introduction to DC-DC Converters

Isolated DC-DC converters electrically separate the input and output through transformers, providing enhanced safety and noise reduction in sensitive applications. Non-isolated DC-DC converters directly connect input and output grounds, offering higher efficiency and simpler design for low-voltage regulation and battery-powered devices. Both types convert DC voltage levels efficiently, but isolation plays a crucial role in applications requiring galvanic separation and protection from high voltage spikes.

What is an Isolated DC-DC Converter?

An isolated DC-DC converter uses galvanic isolation, typically through a transformer, to separate input and output circuits, enhancing safety and noise reduction. It effectively prevents direct current flow between the source and load, which is essential in applications requiring electrical isolation for protection or signal integrity. This contrasts with non-isolated converters, where input and output share a common ground, limiting their use in sensitive or hazardous environments.

What is a Non-Isolated DC-DC Converter?

A non-isolated DC-DC converter directly connects the input and output grounds, allowing energy transfer without electrical isolation, which simplifies design and improves efficiency. Common types include buck, boost, and buck-boost converters, used extensively in battery-powered and low-voltage applications due to their compact size and cost-effectiveness. Unlike isolated converters, non-isolated variants lack galvanic isolation, making them suitable for systems where ground reference sharing is acceptable.

Key Differences between Isolated and Non-Isolated Converters

Isolated DC-DC converters provide galvanic isolation, ensuring electrical separation between input and output to enhance safety and reduce noise interference, while non-isolated converters share a common ground, resulting in simpler design and higher efficiency. Isolated converters typically use transformers to transfer power, enabling voltage stepping up or down with isolation, whereas non-isolated converters rely on inductors or capacitors without isolation, making them more compact and cost-effective. The choice between isolated and non-isolated DC-DC converters depends on application requirements such as safety standards, voltage levels, and system complexity.

Advantages of Isolated DC-DC Converters

Isolated DC-DC converters provide galvanic isolation, which enhances safety by preventing direct current flow between input and output, reducing the risk of electrical shock and equipment damage. They offer superior noise reduction and improved electromagnetic interference (EMI) performance, making them ideal for sensitive applications in medical, industrial, and telecommunications fields. Additionally, isolated converters enable flexible voltage level shifting and protection against ground loops, ensuring reliable operation in complex power systems.

Advantages of Non-Isolated DC-DC Converters

Non-isolated DC-DC converters offer higher efficiency due to the absence of transformers, resulting in reduced power loss and increased energy savings. Their simpler design leads to lower cost, smaller size, and easier integration in compact electronic devices. Additionally, non-isolated converters provide faster transient response, making them ideal for applications requiring quick voltage regulation.

Application Areas for Isolated Converters

Isolated DC-DC converters are extensively used in medical equipment, industrial automation, and telecommunications to provide galvanic isolation and enhance safety while preventing ground loops. These converters are essential in applications requiring strict noise reduction and protection from high voltage spikes, such as in power supplies for sensitive electronics and renewable energy systems. In contrast, non-isolated converters typically serve low-voltage applications like battery-powered devices and embedded systems where isolation is not critical.

Application Areas for Non-Isolated Converters

Non-isolated DC-DC converters are commonly used in low-voltage applications such as battery-powered devices, point-of-load regulation in computer motherboards, and automotive electronics where direct electrical connection between input and output is essential. Their simple design allows efficient voltage step-down or step-up with minimal cost and size, making them ideal for portable gadgets, LED drivers, and DC motor controllers. Typical non-isolated topologies include buck, boost, and buck-boost converters, optimized for applications demanding compactness and high efficiency without galvanic isolation.

Efficiency and Performance Comparison

Isolated DC-DC converters provide galvanic isolation, enhancing safety and noise immunity but often exhibit slightly lower efficiency due to additional components like transformers, which introduce core and copper losses. Non-isolated DC-DC converters typically achieve higher efficiency levels, often above 90%, because of simpler circuitry and reduced energy dissipation, making them ideal for applications requiring compact size and high power density. Performance-wise, isolated converters excel in applications demanding high voltage isolation and noise suppression, while non-isolated converters deliver superior efficiency and faster transient response in low-voltage, high-current scenarios.

Choosing the Right DC-DC Converter for Your Design

When choosing the right DC-DC converter for your design, consider that isolated converters provide galvanic isolation, enhancing safety and reducing noise in sensitive applications such as medical devices and industrial systems. Non-isolated converters offer higher efficiency, smaller size, and lower cost, making them ideal for battery-powered electronics and point-of-load voltage regulation. Evaluating factors like isolation requirements, efficiency, size constraints, and budget helps determine whether an isolated or non-isolated DC-DC converter best fits your project's needs.

Galvanic isolation

Isolated DC-DC converters provide galvanic isolation between input and output for enhanced safety and noise reduction, while non-isolated converters lack this feature, connecting input and output grounds directly.

Flyback topology

Flyback topology in isolated DC-DC converters provides galvanic isolation and enhanced safety compared to non-isolated converters, making it ideal for high-voltage and sensitive applications.

Buck converter

Isolated DC-DC buck converters provide galvanic isolation and enhanced safety for sensitive applications, while non-isolated buck converters offer higher efficiency and simpler design by directly connecting input and output grounds.

Common-mode noise

Isolated DC-DC converters significantly reduce common-mode noise due to galvanic isolation between input and output, whereas non-isolated converters often exhibit higher common-mode noise levels because of the shared ground reference.

Transformer coupling

Isolated DC-DC converters use transformer coupling for galvanic isolation and voltage scaling, while non-isolated converters rely on inductor-based coupling without electrical isolation.

Ground loop

Isolated DC-DC converters prevent ground loop issues by electrically separating input and output grounds, whereas non-isolated converters share a common ground, increasing the risk of ground loop interference.

Forward converter

The isolated Forward DC-DC converter offers galvanic isolation and enhanced safety for sensitive electronics, while the non-isolated Forward converter provides higher efficiency and simpler design by directly connecting input and output grounds.

Efficiency trade-off

Isolated DC-DC converters provide galvanic isolation improving safety but typically exhibit lower efficiency due to additional transformer losses compared to non-isolated converters, which offer higher efficiency by directly regulating voltage without isolation components.

SEPIC converter

A SEPIC converter, as a non-isolated DC-DC converter, offers flexible voltage output ranges with continuous input current, whereas isolated DC-DC converters provide galvanic isolation enhancing safety and noise reduction but typically involve more complex designs and components.

Input-to-output referencing

Isolated DC-DC converters use transformers to provide galvanic isolation between input and output, enabling independent input-to-output referencing, whereas non-isolated converters share a common ground, linking input and output reference directly.

isolated DC-DC converter vs non-isolated DC-DC converter Infographic

njnir.com

njnir.com