Brushless DC motors offer higher efficiency and longer lifespan compared to brushed DC motors due to the absence of brushes, which reduces friction and wear. They provide improved speed control, lower electromagnetic interference, and require less maintenance. Brushed DC motors are simpler and cheaper but suffer from brush and commutator wear, limiting their durability and performance in demanding applications.

Table of Comparison

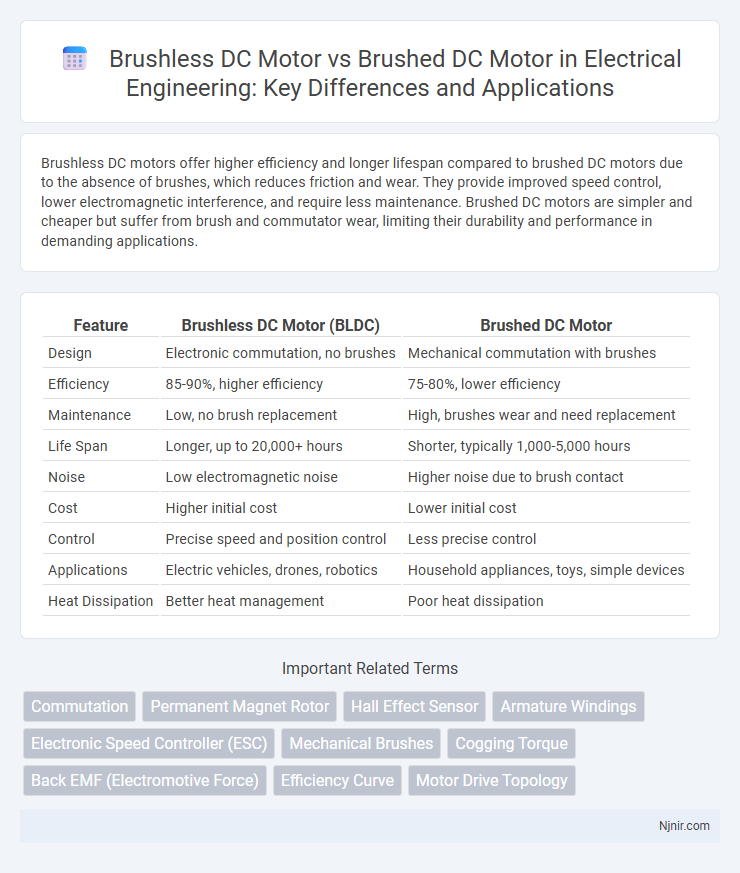

| Feature | Brushless DC Motor (BLDC) | Brushed DC Motor |

|---|---|---|

| Design | Electronic commutation, no brushes | Mechanical commutation with brushes |

| Efficiency | 85-90%, higher efficiency | 75-80%, lower efficiency |

| Maintenance | Low, no brush replacement | High, brushes wear and need replacement |

| Life Span | Longer, up to 20,000+ hours | Shorter, typically 1,000-5,000 hours |

| Noise | Low electromagnetic noise | Higher noise due to brush contact |

| Cost | Higher initial cost | Lower initial cost |

| Control | Precise speed and position control | Less precise control |

| Applications | Electric vehicles, drones, robotics | Household appliances, toys, simple devices |

| Heat Dissipation | Better heat management | Poor heat dissipation |

Introduction to DC Motors

Brushless DC motors (BLDC) offer higher efficiency, longer lifespan, and reduced maintenance compared to brushed DC motors due to the absence of brushes and commutators. Brushed DC motors rely on physical brushes to deliver current, causing friction and wear, which limits their operational durability. BLDC motors utilize electronic commutation, resulting in smoother operation, less noise, and better speed control in various applications.

Fundamental Working Principles

Brushless DC motors operate using electronic commutation, where a controller sequentially energizes the stator windings to create a rotating magnetic field that drives the rotor equipped with permanent magnets. Brushed DC motors rely on mechanical commutation, using brushes and a commutator to switch current flow through the rotor windings, generating torque via electromagnetic interaction. The absence of brushes in brushless motors reduces wear and electrical noise, enhancing efficiency and durability compared to brushed motor designs.

Construction Differences

Brushless DC motors feature a rotor with permanent magnets and a stator containing the windings, contrasting with brushed DC motors where the rotor holds the windings and the stator has permanent magnets. The absence of brushes in brushless motors eliminates the need for a commutator, reducing mechanical wear and enhancing reliability. This fundamental construction difference results in higher efficiency and lower maintenance requirements for brushless DC motors compared to their brushed counterparts.

Efficiency Comparison

Brushless DC motors exhibit higher efficiency than brushed DC motors due to the elimination of brush friction and commutator losses, resulting in reduced energy consumption and heat generation. The absence of brushes allows for more precise electronic commutation, improving power delivery and extending motor lifespan. Typical efficiency ratings for brushless DC motors range from 85% to 90%, whereas brushed DC motors generally achieve 75% to 80%, making brushless motors superior in applications demanding energy efficiency.

Performance and Speed Control

Brushless DC motors offer superior performance with higher efficiency, longer lifespan, and reduced maintenance compared to brushed DC motors due to the absence of brushes and commutators. Speed control in brushless motors is more precise and smoother, achieved through electronic controllers that adjust the stator's magnetic field, while brushed motors rely on mechanical commutation leading to less accurate control and increased wear. This makes brushless DC motors ideal for applications requiring consistent speed, high torque, and reliable performance under varying loads.

Maintenance and Longevity

Brushless DC motors require significantly less maintenance than brushed DC motors due to the absence of brushes and commutators, which are prone to wear and need regular replacement. The lack of mechanical friction in brushless motors results in longer operational life and improved reliability, making them ideal for continuous or high-power applications. Brushed DC motors have a shorter lifespan because their brushes degrade over time, leading to more frequent servicing and potential downtime.

Noise and Electromagnetic Interference

Brushless DC motors produce significantly less noise due to the absence of brush friction and mechanical contact, resulting in quieter operation compared to brushed DC motors. The lack of brushes also reduces sparking and electromagnetic interference (EMI), minimizing electromagnetic noise that can disrupt nearby sensitive electronics. This makes brushless DC motors preferable in applications requiring low acoustic emissions and minimal EMI, such as medical devices and precision instruments.

Applications in the Industry

Brushless DC motors dominate industries requiring high efficiency and low maintenance, such as robotics, aerospace, and electric vehicles, due to their superior torque-to-weight ratio and longer lifespan. Brushed DC motors remain preferred in cost-sensitive applications like household appliances and small power tools where simplicity and lower upfront costs are crucial. Industrial automation and conveyor systems increasingly favor brushless variants for precise speed control and reduced electromagnetic interference.

Cost Analysis and Affordability

Brushless DC motors typically have higher upfront costs due to their complex electronic controllers and permanent magnets but offer lower maintenance expenses and longer lifespans, reducing total cost of ownership over time. In contrast, brushed DC motors are more affordable initially with simpler construction and less expensive components but incur higher maintenance costs due to brush and commutator wear. For applications prioritizing affordability, brushed DC motors provide cost-effective solutions, while brushless motors deliver greater value in high-performance or long-duration uses despite the initial investment.

Choosing the Right Motor for Your Project

Brushless DC motors offer higher efficiency, longer lifespan, and lower maintenance compared to brushed DC motors, making them ideal for applications requiring precision and durability. Brushed DC motors provide a cost-effective solution with simpler control systems, suitable for projects with budget constraints or low complexity. Evaluating factors such as torque requirements, speed control, maintenance expectations, and overall project goals is essential when choosing between brushless and brushed DC motors.

Commutation

Brushless DC motors use electronic commutation for precise control and higher efficiency, while brushed DC motors rely on mechanical commutation with brushes causing wear and energy loss.

Permanent Magnet Rotor

Brushless DC motors with permanent magnet rotors offer higher efficiency, longer lifespan, and reduced maintenance compared to brushed DC motors due to the absence of brushes and commutators.

Hall Effect Sensor

Brushless DC motors utilize Hall Effect sensors for precise rotor position detection, enabling efficient electronic commutation, while brushed DC motors rely on mechanical brushes and commutators without the need for Hall Effect sensors.

Armature Windings

Brushless DC motors feature stationary armature windings on the stator for enhanced efficiency and reduced wear, whereas brushed DC motors have rotating armature windings on the rotor that require brushes and commutators prone to friction and maintenance.

Electronic Speed Controller (ESC)

Brushless DC motors require an Electronic Speed Controller (ESC) to electronically commutate and regulate motor speed and torque, unlike brushed DC motors that rely on mechanical commutation via brushes and a commutator.

Mechanical Brushes

Brushless DC motors eliminate mechanical brushes, reducing wear, maintenance, and electrical noise compared to brushed DC motors that rely on physical brushes for commutation.

Cogging Torque

Brushless DC motors exhibit significantly lower cogging torque than brushed DC motors, resulting in smoother rotation and improved precision in low-speed applications.

Back EMF (Electromotive Force)

Brushless DC motors generate a more consistent and higher Back EMF compared to brushed DC motors due to their electronic commutation and absence of mechanical brushes, resulting in improved efficiency and reduced electromagnetic interference.

Efficiency Curve

Brushless DC motors exhibit a higher and more consistent efficiency curve across a wide RPM range compared to brushed DC motors, which experience efficiency drops due to friction and brush wear.

Motor Drive Topology

Brushless DC motor drive topology uses electronic commutation with inverter circuits for precise control, offering higher efficiency and lower maintenance compared to the simple mechanical commutation in brushed DC motor topology.

brushless DC motor vs brushed DC motor Infographic

njnir.com

njnir.com