Soft starters reduce the initial inrush current to electric motors, providing smooth startup and protecting against mechanical stress; they are ideal for simple applications with fixed speed requirements. Variable frequency drives (VFDs) offer precise control over motor speed and torque by adjusting the supply frequency and voltage, making them suitable for complex processes needing variable speed and energy efficiency. While soft starters optimize startup performance, VFDs enable full operational flexibility and improved process control in electrical motor applications.

Table of Comparison

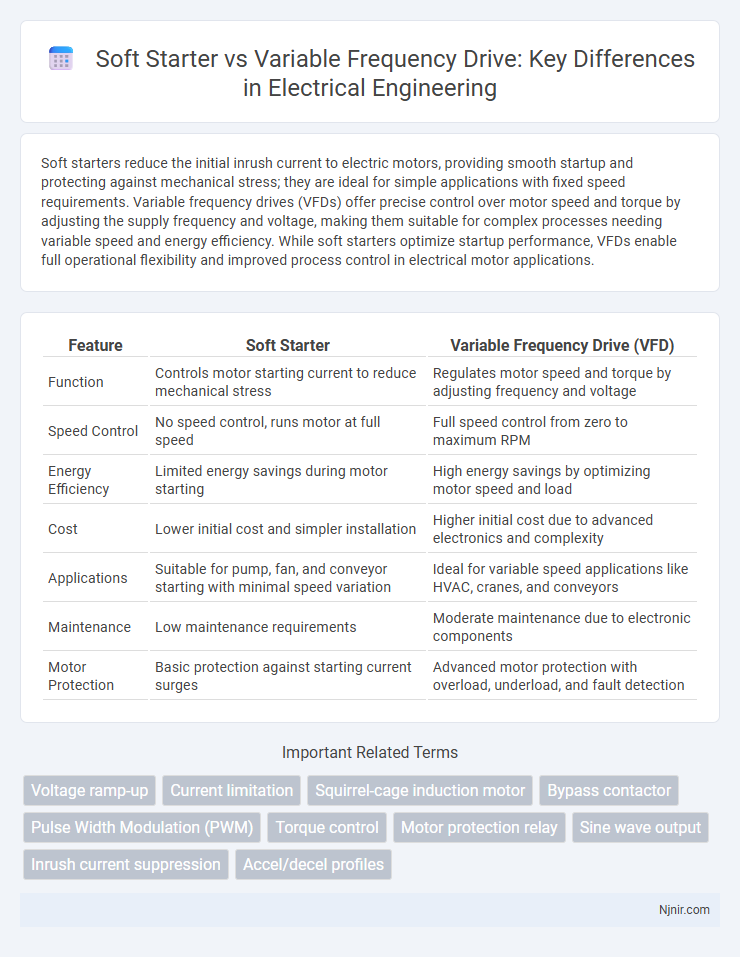

| Feature | Soft Starter | Variable Frequency Drive (VFD) |

|---|---|---|

| Function | Controls motor starting current to reduce mechanical stress | Regulates motor speed and torque by adjusting frequency and voltage |

| Speed Control | No speed control, runs motor at full speed | Full speed control from zero to maximum RPM |

| Energy Efficiency | Limited energy savings during motor starting | High energy savings by optimizing motor speed and load |

| Cost | Lower initial cost and simpler installation | Higher initial cost due to advanced electronics and complexity |

| Applications | Suitable for pump, fan, and conveyor starting with minimal speed variation | Ideal for variable speed applications like HVAC, cranes, and conveyors |

| Maintenance | Low maintenance requirements | Moderate maintenance due to electronic components |

| Motor Protection | Basic protection against starting current surges | Advanced motor protection with overload, underload, and fault detection |

Introduction to Soft Starters and Variable Frequency Drives

Soft starters provide a cost-effective solution for reducing the inrush current and mechanical stress on motors during startup by gradually increasing voltage supply. Variable frequency drives (VFDs) offer precise motor speed control by adjusting the frequency and voltage supplied to the motor, enhancing energy efficiency and operational flexibility. Both technologies improve motor performance but serve different applications based on control complexity and energy management needs.

Basic Principles of Soft Starters

Soft starters regulate motor starting current by gradually ramping up voltage using thyristors to reduce mechanical stress and electrical peak loads. This technology provides smooth acceleration without altering the motor's operating frequency, ensuring a simple and cost-effective solution for reducing inrush current. Compared to variable frequency drives (VFDs), soft starters primarily control voltage during startup rather than continuously adjusting speed or torque.

How Variable Frequency Drives Operate

Variable Frequency Drives (VFDs) control motor speed by varying the frequency and voltage supplied to the electric motor, enabling precise speed and torque regulation. This modulation reduces energy consumption and minimizes mechanical stress during startup and operation compared to traditional methods like soft starters. VFDs are essential in applications requiring continuous speed adjustment and enhanced process control, such as HVAC systems, conveyors, and pump drives.

Key Differences Between Soft Starters and VFDs

Soft starters primarily control motor startup by gradually increasing voltage to reduce inrush current and mechanical stress, whereas variable frequency drives (VFDs) regulate both voltage and frequency to provide precise speed and torque control throughout operation. Soft starters are typically cost-effective solutions for simple applications requiring smooth startups, while VFDs offer advanced energy savings, process control, and flexibility across a wide range of industrial uses. Unlike soft starters, VFDs enable continuous motor speed adjustment, improving performance and efficiency in variable load conditions.

Applications of Soft Starters in Industry

Soft starters are widely used in industries for reducing inrush current and mechanical stress during the startup of large electric motors, particularly in applications such as pumps, fans, and compressors where gradual acceleration is needed. They are ideal for conveyor systems and mixers that require smooth starting without the complex speed control provided by variable frequency drives (VFDs). Soft starters offer cost-effective solutions for motor protection and energy efficiency in processes that do not demand continuous speed variation.

Industrial Uses for Variable Frequency Drives

Variable Frequency Drives (VFDs) dominate industrial applications due to their precise motor speed control, energy efficiency, and reduced mechanical stress. Industries leverage VFDs in processes requiring variable torque and speed adjustments such as conveyors, pumps, and HVAC systems, enhancing operational flexibility and lifespan of equipment. Unlike soft starters, which only control motor startup, VFDs offer continuous modulation of speed and torque, crucial for optimizing production performance in complex industrial systems.

Energy Efficiency: Soft Starter vs VFD

Variable Frequency Drives (VFDs) offer superior energy efficiency by precisely controlling motor speed and torque, reducing power consumption during partial load conditions. Soft starters primarily minimize inrush current and mechanical stress at startup but do not provide continuous energy savings during operation. For applications requiring variable speed control and ongoing energy reduction, VFDs are the optimal choice.

Cost Comparison: Installation and Maintenance

Soft starters generally have a lower initial installation cost compared to variable frequency drives (VFDs) due to simpler components and reduced wiring complexity. Maintenance expenses for soft starters are typically minimal because of fewer moving parts and less complex electronics, whereas VFDs require more frequent servicing and potential firmware updates to ensure optimal performance. Over time, the higher upfront investment in VFDs can be offset by energy savings and improved motor control efficiency, but soft starters remain the cost-effective choice for basic start-stop applications.

Selection Criteria for Soft Starters and VFDs

Selection criteria for soft starters emphasize applications requiring smooth motor starting with reduced inrush current and mechanical stress, typically in pumps, conveyors, and fans operating at fixed speeds. Variable frequency drives (VFDs) are preferred when precise speed control, energy savings, and process flexibility are critical, especially in HVAC systems, centrifugal pumps, and compressors. Key factors influencing the choice include load type, desired speed variation, torque requirements, and energy efficiency goals.

Pros and Cons of Soft Starters vs Variable Frequency Drives

Soft starters provide a cost-effective and simple solution for reducing inrush current during motor startup, offering smooth acceleration without complex control. Variable Frequency Drives (VFDs) excel in precise speed control, energy savings, and enhanced process control, but involve higher initial investment and more intricate installation. While soft starters are ideal for basic applications requiring reduced mechanical stress, VFDs deliver superior performance in variable-speed operations and energy efficiency.

Voltage ramp-up

Soft starters provide a controlled voltage ramp-up to minimize motor inrush current, while variable frequency drives offer precise voltage and frequency ramp-up for optimized motor speed and torque control.

Current limitation

Soft starters limit inrush current by gradually ramping voltage during motor startup, while variable frequency drives precisely control current by adjusting motor speed and frequency for optimal performance.

Squirrel-cage induction motor

Soft starters reduce inrush current and mechanical stress during startup of squirrel-cage induction motors, while variable frequency drives provide precise speed and torque control by modulating motor voltage and frequency.

Bypass contactor

A bypass contactor in soft starters reduces energy loss and heat generation by directly connecting the motor to the power supply after startup, unlike variable frequency drives that continuously regulate motor speed without bypassing.

Pulse Width Modulation (PWM)

Variable frequency drives (VFDs) use Pulse Width Modulation (PWM) to precisely control motor speed and torque by varying voltage and frequency, unlike soft starters that only reduce initial current without speed regulation.

Torque control

Variable frequency drives offer precise torque control by adjusting motor speed and frequency continuously, unlike soft starters which provide limited torque control primarily during motor startup.

Motor protection relay

Soft starters reduce inrush current and mechanical stress during motor startup, while variable frequency drives provide precise speed control and advanced motor protection relays monitor parameters like overload, phase failure, and ground faults to ensure motor safety.

Sine wave output

Variable frequency drives provide a smooth sine wave output that enhances motor efficiency and reduces harmonic distortion, unlike soft starters which typically generate a non-sinusoidal voltage waveform.

Inrush current suppression

Soft starters reduce inrush current by gradually increasing voltage during motor startup, while variable frequency drives suppress inrush current by controlling both voltage and frequency for precise motor acceleration.

Accel/decel profiles

Soft starters provide fixed acceleration and deceleration profiles by gradually ramping voltage to reduce motor inrush current, while variable frequency drives offer fully customizable acceleration and deceleration curves by controlling motor speed and frequency precisely.

soft starter vs variable frequency drive Infographic

njnir.com

njnir.com