Relays are electrical switches operated by a small control signal to open or close circuits, suitable for low power applications, while contactors are designed to handle higher current loads in industrial settings. Contactor coils consume more power and are built for frequent switching in heavy-duty environments, offering robust performance with features like arc suppression. Relays provide precise control in circuits requiring low voltage, whereas contactors excel in motor control and power distribution systems.

Table of Comparison

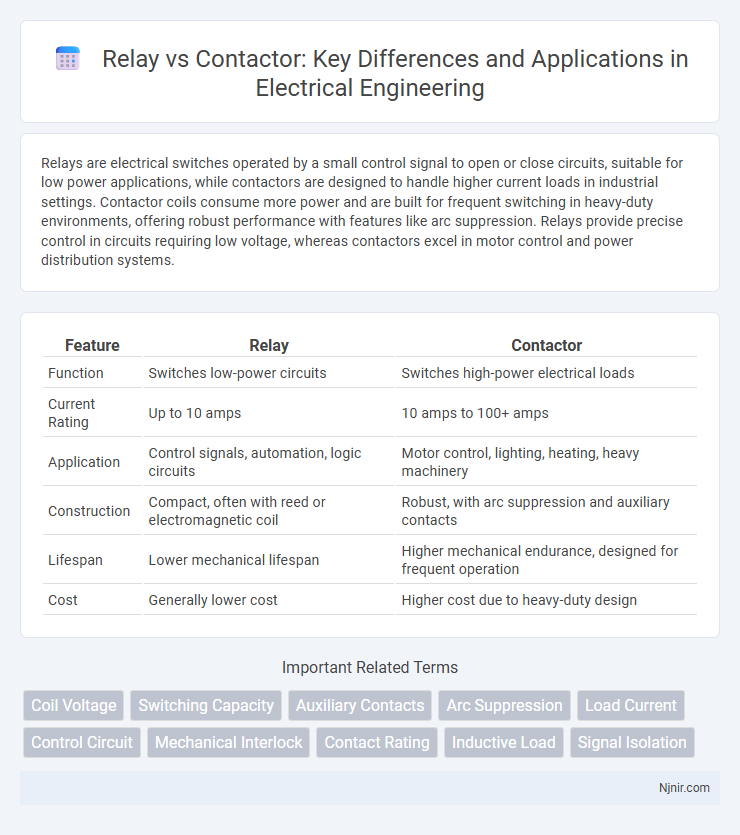

| Feature | Relay | Contactor |

|---|---|---|

| Function | Switches low-power circuits | Switches high-power electrical loads |

| Current Rating | Up to 10 amps | 10 amps to 100+ amps |

| Application | Control signals, automation, logic circuits | Motor control, lighting, heating, heavy machinery |

| Construction | Compact, often with reed or electromagnetic coil | Robust, with arc suppression and auxiliary contacts |

| Lifespan | Lower mechanical lifespan | Higher mechanical endurance, designed for frequent operation |

| Cost | Generally lower cost | Higher cost due to heavy-duty design |

Introduction to Relays and Contactors

Relays and contactors are electromechanical switches used to control electrical circuits, with relays typically designed for low-power applications and contactors engineered to handle higher current loads in industrial environments. Both devices operate via an electromagnetic coil that opens or closes contacts to control the flow of electricity, but contactors feature more robust construction, enabling them to switch large motors and heavy electrical equipment safely. Understanding the differences in their design, application voltage, and current ratings is crucial for selecting the appropriate control component in automated and power control systems.

Core Functions and Applications

Relays are electromagnetic switches primarily used for low-current signal switching and control in circuits, making them ideal for automation and protection applications. Contactors handle higher current loads and are designed for switching electric motors, lighting, and heating equipment in industrial environments. The core function of relays is precise control with fast response, while contactors focus on safely managing heavy electrical loads in power distribution systems.

Design and Construction Differences

Relays feature compact, lightweight designs with low power consumption and typically incorporate electromagnetic coils and a set of mechanical or solid-state contacts suitable for low current applications. Contactors are built with robust, heavy-duty construction, including larger electromagnetic coils and multiple high-capacity contacts to handle high voltage and high current loads in industrial environments. The durability and thermal management in contactors are enhanced by features like arc chutes and heat-resistant insulation, distinguishing them from the simpler relay design.

Operational Voltage and Current Ratings

Relays typically handle lower operational voltage and current ratings, ideal for control circuits with voltages up to 250V AC and currents usually below 15A. Contactors are designed for higher operational voltage and current ratings, commonly managing loads up to 600V AC and currents exceeding 100A for industrial motor control applications. The selection depends heavily on the specific voltage and current requirements of the electrical system to ensure safe and efficient operation.

Control Circuit Characteristics

Relays feature low-power control circuits designed for signal-level switching, making them ideal for sensitive electronic applications. Contactors possess robust control circuits built to handle high inrush currents, enabling direct control of heavy electrical loads such as motors and lighting systems. The coil voltage ratings of contactors are generally matched with industrial power standards, whereas relays commonly operate at lower voltages for control panels.

Switching Capacity and Load Types

Relays typically handle lower switching capacities, suitable for control circuits and light loads up to a few amps, whereas contactors are designed for high switching capacities, managing heavy electrical loads such as motors and industrial equipment often exceeding several hundred amps. Contactors feature robust contacts engineered to withstand frequent high-current operations and inductive loads, while relays are optimized for low-power, signal-level switching with limited endurance under heavy load conditions. Understanding the load type--resistive, inductive, or capacitive--is crucial since contactors can handle inductive motor loads with arc suppression, unlike most relays which are better suited for resistive or signal-level loads.

Typical Use Cases in Electrical Systems

Relays are commonly used for low-power control circuits, such as signal switching and automation in residential and commercial electrical systems. Contactors handle high-current loads in industrial applications, including motor starters, lighting control, and heating systems. Their design optimizes reliability and safety in controlling electrical circuits based on the system's power requirements.

Advantages and Disadvantages of Relays vs Contactors

Relays offer advantages such as precise control in low-voltage circuits, compact size, and faster switching speeds, making them ideal for signal-level applications, but they are limited by lower current capacities and less durability under heavy loads. Contactors excel in handling high-voltage and high-current electrical loads, provide enhanced durability and thermal protection, and are suitable for industrial motor control, though they tend to be larger, noisier, and slower compared to relays. Selecting between relays and contactors depends on the application's voltage, current requirements, and environmental conditions, balancing the trade-offs between size, speed, load capacity, and longevity.

Selection Criteria for Application

Selection criteria for choosing between a relay and a contactor involve considering load type, current rating, and switching frequency. Relays are suitable for low-current control circuits, offering precise switching for signal-level loads, while contactors handle higher currents in motor control and heavy industrial applications. Voltage rating, coil control voltage, and environmental factors like temperature and vibration also influence the optimal choice for reliable performance.

Conclusion: Choosing Between Relay and Contactor

Relays are ideal for low-current, signal-level switching, offering compact size and faster operation, while contactors are designed for high-current applications requiring robust, durable contacts and enhanced safety features. Selecting between a relay and a contactor depends primarily on the voltage, current rating, and application type, with contactors favored in industrial motor control and relays preferred in electronic circuits. Evaluating load requirements and switching frequency ensures optimal performance and longevity for electrical control systems.

Coil Voltage

Relay coil voltages typically range from 5V to 48V DC, whereas contactor coil voltages commonly span from 24V to 600V AC or DC, making contactors suitable for higher power applications.

Switching Capacity

Contactors typically have a higher switching capacity than relays, enabling them to handle larger electrical loads and industrial applications more effectively.

Auxiliary Contacts

Auxiliary contacts in relays typically handle lower currents for control circuits, while those in contactors are designed to support higher loads and provide more robust switching capabilities for industrial applications.

Arc Suppression

Contactors require advanced arc suppression techniques using magnetic blowouts or arc chutes to handle high current interruptions, whereas relays typically use simpler arc suppression methods due to lower current loads.

Load Current

Relays typically manage low to moderate load currents up to around 10-20 amps, while contactors are designed for high load currents exceeding 30 amps, commonly used in industrial motor control and heavy electrical equipment.

Control Circuit

Relays offer compact, low-current control for signal switching in control circuits, while contactors handle high-current loads with robust design for industrial motor control.

Mechanical Interlock

Mechanical interlock in contactors prevents simultaneous closing of multiple contacts to avoid electrical faults, whereas relays typically lack this physical safety feature.

Contact Rating

Contactors typically have higher contact ratings than relays, enabling them to handle larger current loads and industrial applications more effectively.

Inductive Load

Contactors are preferred over relays for controlling inductive loads due to their higher current capacity, robust construction, and ability to handle inrush currents without contact welding.

Signal Isolation

Relays provide electrical signal isolation through an electromagnetic coil separating control and load circuits, while contactors, designed for higher power switching, offer less inherent signal isolation and are primarily used for controlling heavy-duty electrical loads.

relay vs contactor Infographic

njnir.com

njnir.com