Split-phase systems provide two equal voltages that are 180 degrees out of phase, commonly used in residential electrical service for single-phase loads. Polyphase systems, such as three-phase power, deliver multiple sinusoidal voltages separated by equal phase angles, enabling more efficient power transmission and smoother operation of three-phase motors. The choice between split-phase and polyphase depends on the application requirements, with polyphase preferred for industrial machinery due to its higher power capacity and balanced load distribution.

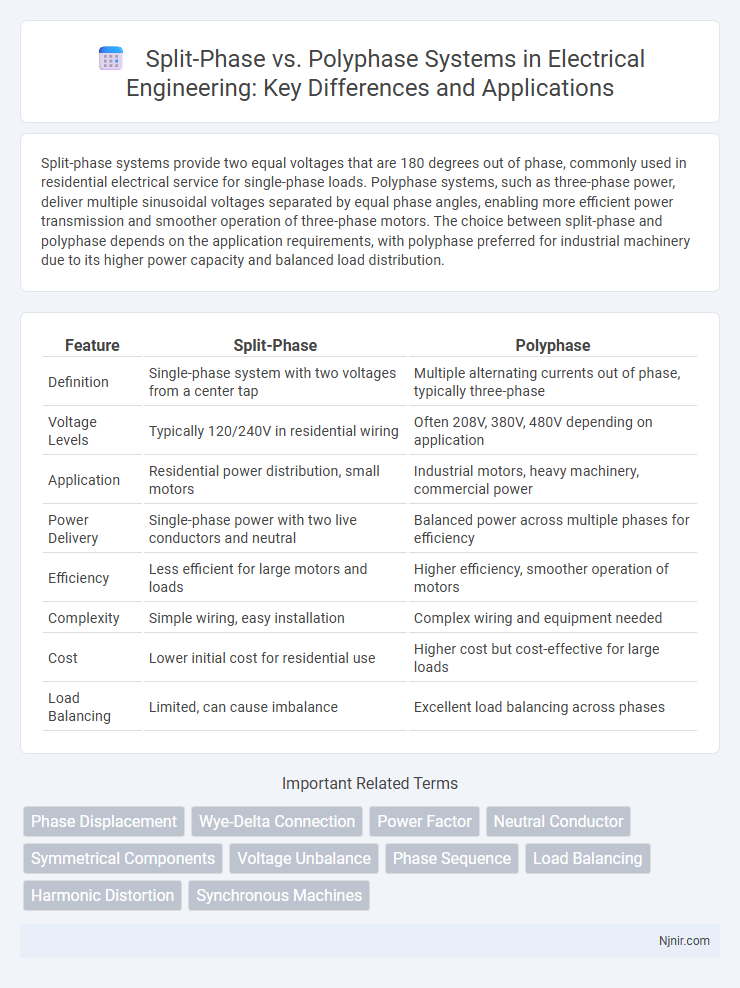

Table of Comparison

| Feature | Split-Phase | Polyphase |

|---|---|---|

| Definition | Single-phase system with two voltages from a center tap | Multiple alternating currents out of phase, typically three-phase |

| Voltage Levels | Typically 120/240V in residential wiring | Often 208V, 380V, 480V depending on application |

| Application | Residential power distribution, small motors | Industrial motors, heavy machinery, commercial power |

| Power Delivery | Single-phase power with two live conductors and neutral | Balanced power across multiple phases for efficiency |

| Efficiency | Less efficient for large motors and loads | Higher efficiency, smoother operation of motors |

| Complexity | Simple wiring, easy installation | Complex wiring and equipment needed |

| Cost | Lower initial cost for residential use | Higher cost but cost-effective for large loads |

| Load Balancing | Limited, can cause imbalance | Excellent load balancing across phases |

Introduction to Split-phase and Polyphase Systems

Split-phase systems utilize two 120V AC lines derived from a single transformer with a center tap, providing 240V for high-power appliances and 120V for standard devices, commonly seen in residential settings. Polyphase systems, particularly three-phase, consist of three alternating currents offset by 120 degrees, enabling more efficient power transmission and smoother operation of industrial motors. The split-phase design simplifies household wiring and energy distribution, while polyphase systems are essential for high-capacity and balanced electrical loads in commercial and industrial environments.

Fundamental Principles of Split-phase Circuits

Split-phase circuits operate by providing two equal voltages out of phase by 180 degrees, derived from a single-phase power source, enabling the delivery of both 120V and 240V for residential applications. This design uses a center-tapped transformer to create two opposite polarity voltages, which balance the load and reduce neutral current. The fundamental principle centers on the use of two voltages that are equal in magnitude but opposite in phase, facilitating efficient power distribution in household wiring systems.

Overview of Polyphase System Configurations

Polyphase system configurations, including common types such as three-phase and six-phase systems, distribute electrical power using multiple alternating currents that are offset in phase angle, enhancing power delivery efficiency and reliability. Three-phase systems, the most prevalent, use three conductors each carrying an AC voltage phase shifted by 120 degrees, enabling smoother power flow and reduced conductor material compared to single-phase or split-phase systems. Advanced configurations like six-phase or twelve-phase systems further reduce harmonic distortion and improve power quality in specialized industrial and transmission applications.

Voltage and Current Characteristics Comparison

Split-phase systems deliver two 120V AC lines with a center-tapped neutral, enabling 240V supply for heavy appliances and balanced current flow in residential wiring. Polyphase systems, commonly three-phase, provide multiple alternating currents offset by 120 degrees, resulting in consistent power delivery, reduced vibration, and increased efficiency for industrial motors and large equipment. Voltage in polyphase setups is typically higher, ranging from 208V to 480V or more, while current remains balanced across phases, minimizing neutral current and enhancing overall system stability.

Applications in Residential and Industrial Settings

Split-phase power systems are commonly utilized in residential settings to efficiently deliver 120/240 volts, supporting household appliances and lighting with a simpler wiring infrastructure. Polyphase power systems, particularly three-phase, dominate industrial applications due to their ability to supply consistent, balanced power for heavy machinery, motors, and large-scale equipment, improving operational efficiency. The choice between split-phase and polyphase hinges on load requirements, with split-phase ideal for lower power demands and polyphase suited for high-power and continuous industrial operations.

Power Delivery Efficiency and Distribution

Split-phase power delivers efficient energy for residential loads by providing two 120-volt lines allowing balanced load distribution and reduced wiring complexity. Polyphase systems, typically three-phase, enhance power delivery efficiency for industrial and commercial applications through continuous power flow, reduced conductor sizes, and improved voltage regulation. The inherent design of polyphase distribution minimizes losses and supports high-capacity equipment, making it optimal for large-scale power grids.

Advantages and Limitations of Split-phase Systems

Split-phase systems offer simplicity and cost-effectiveness for residential electrical distribution by providing two 120V lines and a neutral, enabling both 120V and 240V loads with balanced power delivery. Their limitations include lower efficiency and capacity compared to polyphase systems, making them less suitable for heavy industrial loads or three-phase motor operation. Despite restricted power handling, split-phase systems excel in household applications due to ease of installation and widespread availability.

Advantages and Limitations of Polyphase Systems

Polyphase systems offer enhanced power efficiency and smoother torque in electrical machines compared to split-phase systems, making them ideal for industrial applications. These systems enable balanced load distribution and reduced conductor material usage, resulting in improved reliability and lower energy losses. However, polyphase systems require more complex wiring and equipment, increasing initial installation costs and maintenance challenges.

Cost Implications and Installation Complexity

Split-phase electrical systems generally incur lower installation costs due to simpler wiring and fewer components, making them ideal for residential setups. Polyphase systems, often used in commercial and industrial applications, involve higher upfront costs and complex installation because they require multiple conductors and specialized equipment. The increased complexity in polyphase installations typically leads to higher labor costs and extended installation times compared to split-phase systems.

Future Trends in Electrical Power Systems

Future trends in electrical power systems emphasize the integration of polyphase systems due to their enhanced efficiency and reliability in distributing three-phase power for industrial and large-scale renewable energy applications. Split-phase systems remain relevant in residential settings for delivering balanced single-phase loads, but the shift towards decentralized smart grids and electric vehicle infrastructure accelerates the adoption of advanced polyphase configurations for improved power quality and load management. Innovations in power electronics, such as advanced inverters and fault detection technologies, further optimize polyphase systems, driving their dominance in future grid modernization efforts.

Phase Displacement

Split-phase systems exhibit a fixed 180-degree phase displacement between two live wires, while polyphase systems, such as three-phase, typically have 120-degree phase displacement to ensure balanced power distribution.

Wye-Delta Connection

Wye-Delta connections in split-phase systems provide single-phase power with neutral grounding, while polyphase Wye-Delta configurations enable efficient three-phase power distribution and motor operation.

Power Factor

Split-phase systems typically have a power factor close to unity due to balanced resistive loads, whereas polyphase systems improve power factor and efficiency by supporting balanced, multiphase loads and enabling the use of power factor correction devices.

Neutral Conductor

The neutral conductor in split-phase systems provides a return path and voltage stabilization for 120V loads, whereas polyphase systems often use a neutral for unbalanced loads but rely primarily on phase conductors for balanced three-phase power delivery.

Symmetrical Components

Symmetrical components analysis decomposes split-phase systems into two equal but opposite phases, while polyphase systems utilize three or more phases to balance loads and reduce harmonic distortion.

Voltage Unbalance

Split-phase systems typically experience less voltage unbalance than polyphase systems due to their symmetrical voltage distribution and simpler load balancing.

Phase Sequence

Split-phase systems use a single-phase input split into two 180-degree out-of-phase voltages, while polyphase systems employ multiple phases with specific phase sequences, typically 120 degrees apart, to ensure balanced power delivery and smooth motor operation.

Load Balancing

Split-phase systems provide basic load balancing by dividing a single-phase supply into two opposing phases, while polyphase systems offer superior load balancing across multiple phases, resulting in enhanced efficiency and reduced electrical losses.

Harmonic Distortion

Split-phase systems typically exhibit higher harmonic distortion due to unbalanced loads, whereas polyphase systems reduce harmonic distortion by distributing power across multiple phases.

Synchronous Machines

Synchronous machines in split-phase systems typically use two windings for starting torque, while polyphase synchronous machines utilize multiple windings to produce a rotating magnetic field and improve efficiency.

Split-phase vs Polyphase Infographic

njnir.com

njnir.com