Six-step commutation offers a simpler control strategy for brushless DC motors by energizing two phases at a time, resulting in a stepped current waveform that produces higher torque ripple and acoustic noise. Sinusoidal commutation provides smooth current waveforms by continuously varying the phase currents in a sinusoidal manner, reducing torque ripple and improving motor efficiency and noise performance. While six-step commutation is easier to implement and cost-effective, sinusoidal commutation enhances precision in speed and position control for applications demanding higher performance.

Table of Comparison

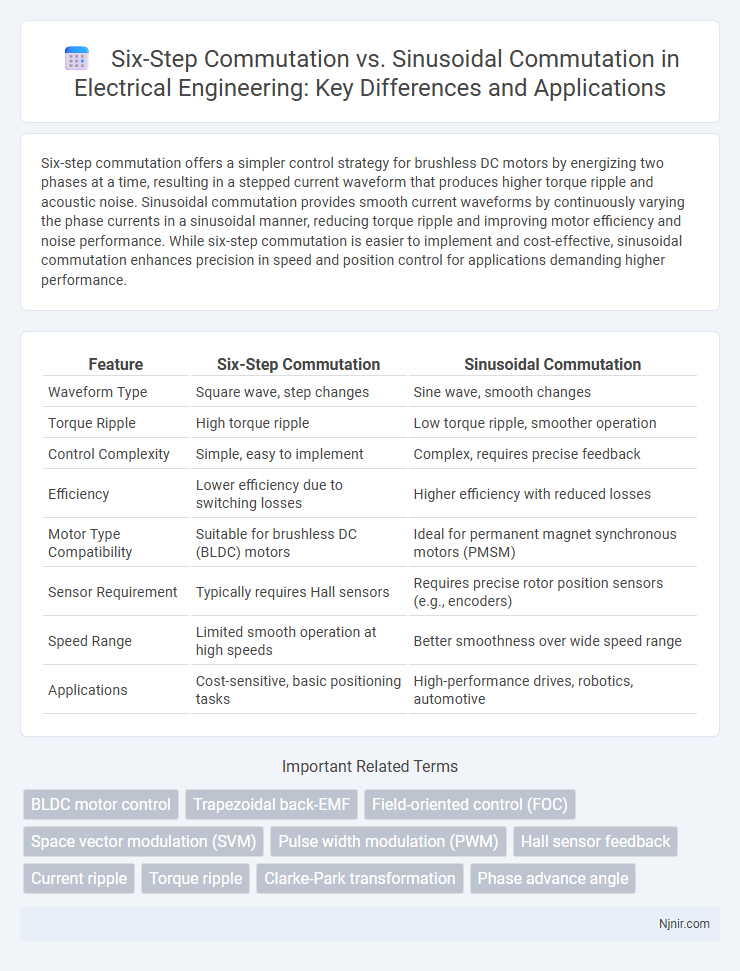

| Feature | Six-Step Commutation | Sinusoidal Commutation |

|---|---|---|

| Waveform Type | Square wave, step changes | Sine wave, smooth changes |

| Torque Ripple | High torque ripple | Low torque ripple, smoother operation |

| Control Complexity | Simple, easy to implement | Complex, requires precise feedback |

| Efficiency | Lower efficiency due to switching losses | Higher efficiency with reduced losses |

| Motor Type Compatibility | Suitable for brushless DC (BLDC) motors | Ideal for permanent magnet synchronous motors (PMSM) |

| Sensor Requirement | Typically requires Hall sensors | Requires precise rotor position sensors (e.g., encoders) |

| Speed Range | Limited smooth operation at high speeds | Better smoothness over wide speed range |

| Applications | Cost-sensitive, basic positioning tasks | High-performance drives, robotics, automotive |

Overview of Motor Commutation Techniques

Six-step commutation, commonly used in brushless DC motors, involves energizing two motor phases at a time in fixed 60-degree intervals, producing a trapezoidal back-EMF waveform that simplifies control and reduces computational requirements. Sinusoidal commutation employs continuous, smooth phase current variations that align with sinusoidal back-EMF, enabling lower torque ripple and quieter operation in permanent magnet synchronous motors (PMSMs). Both techniques serve distinct applications, with six-step commutation favored for cost-effective, high-torque scenarios and sinusoidal commutation preferred for precision and efficiency in high-performance drives.

Principles of Six-Step Commutation

Six-step commutation operates by energizing two motor phases at a time in a fixed sequence, creating a trapezoidal back-EMF waveform that enables efficient torque production in brushless DC motors. The principle relies on switching the stator coils in six discrete steps per electrical revolution, synchronizing with the rotor position detected by Hall sensors or encoders. This method contrasts with sinusoidal commutation, which continuously varies phase currents to generate smooth, sinusoidal back-EMF for reduced torque ripple and quieter operation.

Fundamentals of Sinusoidal Commutation

Sinusoidal commutation involves continuously varying the phase currents in a synchronous motor to produce smooth torque and reduce torque ripple, achieved by generating sine wave current waveforms synchronized with rotor position. This method contrasts with six-step commutation, which uses fixed rectangular current waveforms resulting in higher torque ripple and acoustic noise. Fundamental to sinusoidal commutation is the precise detection of rotor position using sensors or sensorless algorithms, enabling the generation of sinusoidal currents that optimize motor efficiency and performance.

Key Differences Between Six-Step and Sinusoidal Commutation

Six-step commutation utilizes square wave voltage patterns to drive brushless DC motors, resulting in discrete current steps and higher torque ripple compared to sinusoidal commutation. Sinusoidal commutation applies smooth sine wave voltages for each phase, producing continuous torque and reduced vibration, which improves motor efficiency and acoustic performance. The key differences lie in the current waveform shape, torque smoothness, and control complexity, with sinusoidal commutation requiring more advanced algorithms and sensors for precise rotor position feedback.

Efficiency Comparison: Six-Step vs Sinusoidal

Six-step commutation offers simpler control with reduced switching losses, leading to higher efficiency at low to moderate speeds in brushless DC motors. Sinusoidal commutation delivers smoother torque and reduced acoustic noise, improving efficiency under variable loads by minimizing harmonic distortions in current waveforms. Efficiency gains from sinusoidal commutation become significant in precision applications, while six-step remains preferred for cost-sensitive, high-speed operations.

Performance in Torque Ripple and Smoothness

Six-step commutation typically produces higher torque ripple due to its abrupt switching between phases, resulting in less smooth motor operation and increased mechanical vibration. Sinusoidal commutation delivers smoother torque output by continuously modulating current in a sinusoidal waveform, which minimizes torque ripple and enhances overall motor performance. The continuous current transition in sinusoidal commutation reduces acoustic noise and provides improved precision in applications requiring consistent torque delivery.

Control Complexity and Implementation

Six-step commutation employs a simpler six-step switching sequence that reduces control complexity, making it easier to implement on basic microcontrollers with minimal computational resources. Sinusoidal commutation requires generating continuous sinusoidal waveforms for the motor phases, demanding advanced algorithms and precise position feedback, which increases implementation complexity and processing power. While six-step commutation offers straightforward control suitable for low-cost applications, sinusoidal commutation provides smoother torque and efficiency at the expense of higher control and implementation complexity.

Applications Suitability for Each Method

Six-step commutation is widely used in applications requiring simplicity and cost-effectiveness, such as small industrial motors, electric scooters, and household appliances, due to its straightforward control and robust performance at low speeds. Sinusoidal commutation excels in applications demanding smooth torque and reduced acoustic noise, like electric vehicles, robotics, and precision CNC machines, by delivering continuous current waveforms that minimize torque ripple. Each method suits specific needs: six-step commutation favors rugged and budget-conscious designs, while sinusoidal commutation is ideal for high-performance, noise-sensitive, and precision-driven systems.

Cost Implications and Hardware Requirements

Six-step commutation requires simpler hardware components such as basic Hall effect sensors and a less complex inverter design, resulting in lower initial costs and reduced maintenance expenses. Sinusoidal commutation demands advanced position sensors like encoders or resolvers and sophisticated inverter control algorithms, increasing both hardware complexity and overall system cost. The higher precision and efficiency of sinusoidal commutation often justify its elevated investment in applications where performance outweighs budget constraints.

Selecting the Right Commutation Technique

Selecting the right commutation technique is essential for optimizing brushless DC motor performance, where six-step commutation offers simplicity and robustness ideal for low-cost or sensorless applications. Sinusoidal commutation delivers smoother torque and reduced acoustic noise, making it preferable for precision control and applications requiring high efficiency. Evaluating motor specifications, control system complexity, and application demands guides the choice between the discrete torque output of six-step and the continuous torque profile of sinusoidal commutation.

BLDC motor control

Six-step commutation controls BLDC motors by energizing stator coils in fixed sequences for simplicity and torque ripple, while sinusoidal commutation uses continuous current waveforms matching motor back-EMF to achieve smoother operation and higher efficiency.

Trapezoidal back-EMF

Six-step commutation efficiently drives motors with trapezoidal back-EMF by switching phases in discrete intervals, while sinusoidal commutation smoothly modulates current to match sinusoidal back-EMF for reduced torque ripple.

Field-oriented control (FOC)

Field-oriented control (FOC) enables precision torque and speed regulation in brushless motors by using sinusoidal commutation to smoothly control current vectors, whereas six-step commutation applies simpler, less efficient rectangular current waveforms resulting in higher torque ripple and reduced motor efficiency.

Space vector modulation (SVM)

Six-step commutation offers simpler control with fixed voltage vectors, whereas sinusoidal commutation combined with Space Vector Modulation (SVM) enables smoother torque production and higher efficiency by generating optimized voltage vectors for precise motor control.

Pulse width modulation (PWM)

Six-step commutation uses PWM to deliver fixed 120-degree pulses generating trapezoidal waveforms, whereas sinusoidal commutation employs PWM to create smoothly varying voltage waveforms for minimized torque ripple and enhanced motor efficiency.

Hall sensor feedback

Six-step commutation uses Hall sensor feedback for discrete rotor position detection enabling simple switching, while sinusoidal commutation relies on Hall sensors for precise rotor angle measurements to optimize smooth current waveform control.

Current ripple

Six-step commutation generates higher current ripple compared to sinusoidal commutation, which produces smoother current waveforms and reduces electromagnetic interference in motor drives.

Torque ripple

Six-step commutation exhibits higher torque ripple due to abrupt current transitions, while sinusoidal commutation reduces torque ripple by smoothly varying currents, resulting in more consistent motor torque output.

Clarke-Park transformation

Six-step commutation uses a fixed six-step sequence without Clarke-Park transformation, while sinusoidal commutation relies on Clarke-Park transformation to convert three-phase currents into a rotating reference frame for smoother motor control.

Phase advance angle

Six-step commutation typically uses a fixed or zero phase advance angle, whereas sinusoidal commutation dynamically adjusts the phase advance angle to optimize motor torque and efficiency at varying speeds.

six-step commutation vs sinusoidal commutation Infographic

njnir.com

njnir.com