Wirewound resistors offer high precision and superior power handling due to their construction with metal wire coils, making them suitable for high-current applications requiring stability. Film resistors, composed of metal or carbon films deposited on ceramic substrates, provide excellent tolerance, low noise, and better frequency response, ideal for signal processing and low-power circuits. Choosing between wirewound and film resistors depends on the specific requirements of power dissipation, accuracy, and frequency performance in electrical engineering designs.

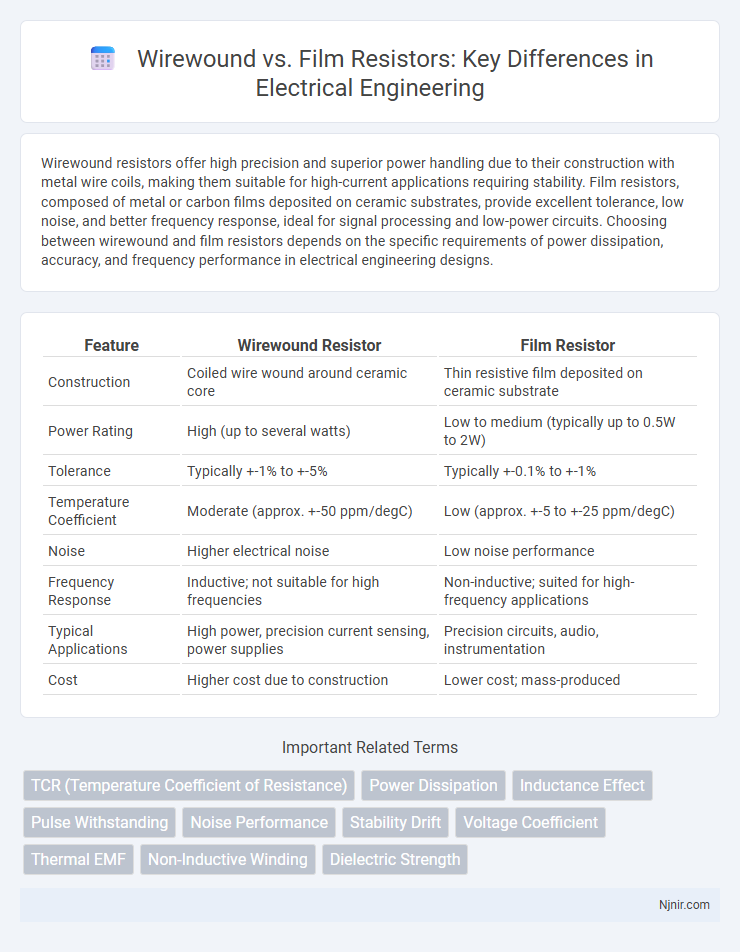

Table of Comparison

| Feature | Wirewound Resistor | Film Resistor |

|---|---|---|

| Construction | Coiled wire wound around ceramic core | Thin resistive film deposited on ceramic substrate |

| Power Rating | High (up to several watts) | Low to medium (typically up to 0.5W to 2W) |

| Tolerance | Typically +-1% to +-5% | Typically +-0.1% to +-1% |

| Temperature Coefficient | Moderate (approx. +-50 ppm/degC) | Low (approx. +-5 to +-25 ppm/degC) |

| Noise | Higher electrical noise | Low noise performance |

| Frequency Response | Inductive; not suitable for high frequencies | Non-inductive; suited for high-frequency applications |

| Typical Applications | High power, precision current sensing, power supplies | Precision circuits, audio, instrumentation |

| Cost | Higher cost due to construction | Lower cost; mass-produced |

Introduction to Wirewound and Film Resistors

Wirewound resistors consist of a metal wire coil wound around a ceramic, plastic, or fiberglass core, known for high power rating and precision in high-frequency applications. Film resistors, including carbon film and metal film types, feature a thin resistive layer deposited on an insulating substrate, offering low noise, tight tolerance, and stability in low to medium power circuits. Both resistors are essential for electronic circuit design, with wirewound resistors favored for durability and film resistors preferred for accuracy and noise reduction.

Construction and Material Differences

Wirewound resistors are constructed by winding a metal wire, typically nichrome or copper-nickel alloy, around an insulating core, providing high power dissipation and precision stability. Film resistors use a thin layer of resistive material such as metal oxide or carbon film deposited on a ceramic substrate, offering compact size and low noise performance. The fundamental material distinction lies in the wire element for wirewound versus the resistive film in film resistors, impacting their electrical characteristics and thermal management.

Electrical Performance Comparison

Wirewound resistors offer superior power handling and high precision with low noise, making them ideal for high-current and high-frequency applications. Film resistors excel in stability, tight tolerance, and low temperature coefficient, providing better performance in low-power and signal conditioning circuits. Electrical performance varies with application demands, where wirewound resistors perform better under thermal stress, while film resistors provide enhanced accuracy and reliability in precision electronics.

Power Rating Capabilities

Wirewound resistors offer superior power rating capabilities, typically ranging from 1 watt to several hundred watts, making them ideal for high-power applications and precision current regulation. Film resistors generally provide lower power ratings, usually up to 2 watts, suitable for low to moderate power circuits with better stability and lower noise. When selecting resistors for high-power dissipation, wirewound types outperform film resistors due to their robust construction and enhanced heat dissipation.

Temperature Stability and Coefficient

Wirewound resistors offer superior temperature stability and a low temperature coefficient, typically around 5 ppm/degC, making them ideal for precision applications where minimal resistance change is critical. Film resistors, especially metal film types, also provide good temperature stability with coefficients ranging from 10 to 50 ppm/degC, balancing cost and performance for many electronic circuits. The choice between wirewound and film resistors depends on the required precision and thermal environment, with wirewound favored in high-power, high-temperature stability scenarios.

Tolerance and Precision Levels

Wirewound resistors offer superior tolerance and precision levels, often achieving tolerances as low as +-0.1%, making them ideal for high-accuracy applications. Film resistors typically feature tolerances around +-1% to +-5%, with precision film resistors reaching down to +-0.1% but generally not matching the stability and precision of wirewound types. The choice between wirewound and film resistors depends on the required accuracy, with wirewound being preferred for tight tolerance and stable performance under varying conditions.

Noise Characteristics in Resistors

Wirewound resistors exhibit significantly lower noise levels due to their metal wire construction, which provides stable resistance and minimal microphonic effects. Film resistors, especially metal film types, generate less noise than carbon composition resistors but can still produce more electrical noise compared to wirewound variants under high-frequency conditions. Noise characteristics in resistors impact signal integrity in precision electronics, making wirewound resistors ideal for low-noise applications requiring high accuracy and stability.

Typical Applications and Use Cases

Wirewound resistors excel in high-power applications such as power supplies, motor controls, and precision current sensing due to their ability to handle high wattage and withstand elevated temperatures. Film resistors are ideal for low-noise, high-frequency circuits, precision analog systems, and consumer electronics where stability, accuracy, and compact size are critical. Typical use cases for wirewound include industrial equipment and power conversion, whereas film resistors dominate in audio devices, instrumentation, and telecommunications.

Cost and Availability Analysis

Wirewound resistors generally have higher manufacturing costs due to their complex construction involving metal wire coils, resulting in higher prices compared to film resistors. Film resistors benefit from mass production techniques, making them widely available and cost-effective for standard applications. Availability of wirewound resistors is more limited and often tailored to specialized uses requiring high power dissipation or precision, while film resistors dominate in low to medium power circuits with broad market presence.

Selection Criteria for Electrical Engineers

Wirewound resistors offer high precision and power rating, making them ideal for applications requiring stability under high temperatures and current loads. Film resistors provide better tolerance and lower noise, suited for high-frequency circuits and environments demanding minimal inductance. Electrical engineers must evaluate factors such as power dissipation, tolerance, frequency response, and thermal stability when selecting between wirewound and film resistors to optimize circuit performance.

TCR (Temperature Coefficient of Resistance)

Wirewound resistors exhibit a significantly lower TCR (Temperature Coefficient of Resistance) compared to film resistors, providing superior temperature stability for precision applications.

Power Dissipation

Wirewound resistors typically offer higher power dissipation ratings than film resistors due to their thicker wire construction and superior heat dissipation properties.

Inductance Effect

Wirewound resistors exhibit higher inductance due to their coiled wire construction, whereas film resistors have significantly lower inductance, making them preferable for high-frequency applications.

Pulse Withstanding

Wirewound resistors offer superior pulse withstanding capability compared to film resistors due to their robust construction and higher power dissipation tolerance.

Noise Performance

Wirewound resistors exhibit lower noise levels due to their metal wire construction, whereas film resistors generate less excess noise and offer better stability, making film resistors preferable for low-noise electronic applications.

Stability Drift

Wirewound resistors exhibit superior stability and minimal drift over time compared to film resistors due to their metal wire construction and lower temperature coefficient.

Voltage Coefficient

Film resistors exhibit a significantly lower voltage coefficient compared to wirewound resistors, resulting in more stable resistance under varying voltage conditions.

Thermal EMF

Wirewound resistors exhibit lower Thermal EMF compared to film resistors, making them preferable in precision low-noise applications.

Non-Inductive Winding

Non-inductive winding in wirewound resistors minimizes inductance by twisting or bifilar winding the wire, making them superior to film resistors in high-frequency, precision applications requiring low inductance.

Dielectric Strength

Film resistors typically offer higher dielectric strength than wirewound resistors, making them more suitable for high-voltage insulation applications.

Wirewound vs Film resistor Infographic

njnir.com

njnir.com