IGBTs (Insulated Gate Bipolar Transistors) offer higher voltage and current handling capabilities, making them ideal for high-power applications such as motor drives and industrial inverters. MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) excel in low-voltage, high-speed switching scenarios due to their faster switching speeds and lower conduction losses. Choosing between IGBT and MOSFET depends on the specific electrical requirements, where efficiency, switching frequency, and voltage ratings must be balanced for optimal performance.

Table of Comparison

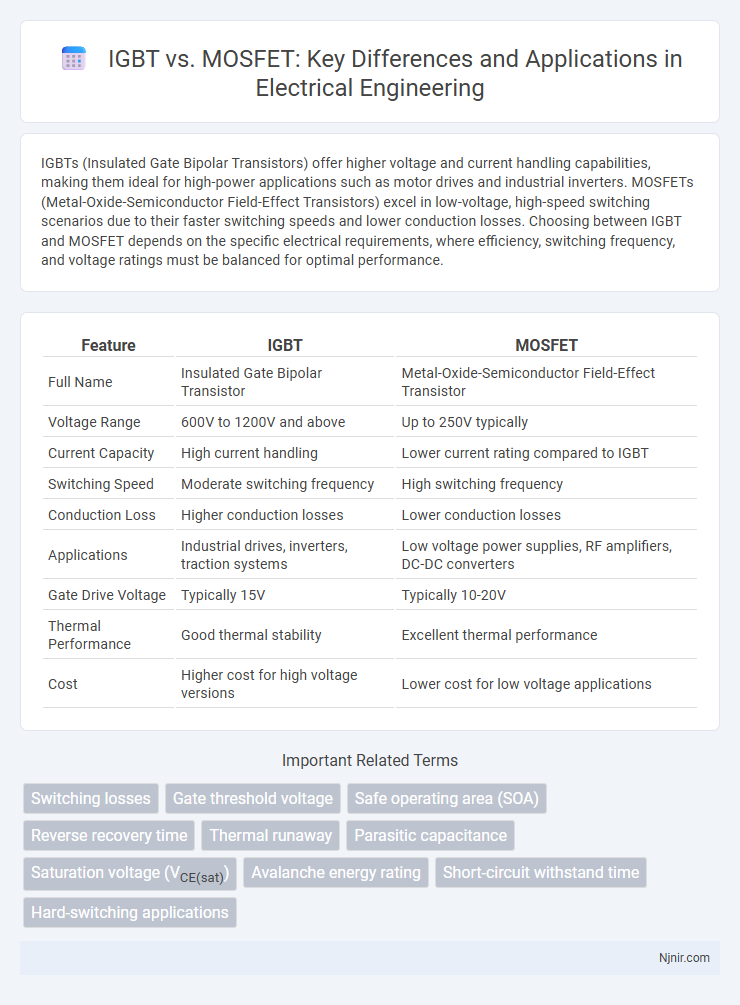

| Feature | IGBT | MOSFET |

|---|---|---|

| Full Name | Insulated Gate Bipolar Transistor | Metal-Oxide-Semiconductor Field-Effect Transistor |

| Voltage Range | 600V to 1200V and above | Up to 250V typically |

| Current Capacity | High current handling | Lower current rating compared to IGBT |

| Switching Speed | Moderate switching frequency | High switching frequency |

| Conduction Loss | Higher conduction losses | Lower conduction losses |

| Applications | Industrial drives, inverters, traction systems | Low voltage power supplies, RF amplifiers, DC-DC converters |

| Gate Drive Voltage | Typically 15V | Typically 10-20V |

| Thermal Performance | Good thermal stability | Excellent thermal performance |

| Cost | Higher cost for high voltage versions | Lower cost for low voltage applications |

Introduction to IGBT and MOSFET

Insulated Gate Bipolar Transistors (IGBTs) combine the high input impedance and fast switching of MOSFETs with the high current and low saturation voltage capability of bipolar transistors, making them ideal for medium to high-power applications. Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs) feature voltage-driven operation with rapid switching speeds and are widely used in low to medium power circuits, especially in high-frequency applications. Both devices serve critical roles in power electronics, with selections based on voltage, current, switching frequency, and efficiency requirements.

Operating Principles of IGBT

IGBT (Insulated Gate Bipolar Transistor) operates by combining the high input impedance of a MOSFET gate with the low on-state power loss of a bipolar transistor, enabling efficient switching in high voltage and power applications. The device controls current flow by using the voltage applied to its gate to modulate the conductivity of a channel between the collector and emitter, allowing for fast switching speeds and high current capabilities. IGBTs are preferred in applications requiring high efficiency and reliability, such as motor drives, inverters, and power grids.

Operating Principles of MOSFET

MOSFETs operate by controlling the voltage applied to the gate terminal, which modulates the conductivity between the drain and source terminals through an electric field. This voltage-driven mechanism allows for rapid switching and low gate current, making MOSFETs highly efficient in high-frequency applications. In contrast to IGBTs, which rely on bipolar conduction and current-driven control, MOSFETs function as majority carrier devices, resulting in faster switching speeds and reduced switching losses.

Key Differences Between IGBT and MOSFET

IGBT (Insulated Gate Bipolar Transistor) combines the high input impedance of a MOSFET with the low on-state power loss of a bipolar transistor, making it ideal for high-voltage and high-current applications. MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) excel in high-speed switching and low-voltage, low-power scenarios due to their faster switching speeds and lower gate drive power. Key differences include IGBT's superior performance in voltage ratings above 600V and higher current capacity, while MOSFETs offer better efficiency and switching frequency at voltages typically below 250V.

Switching Speed Comparison

IGBTs typically have slower switching speeds compared to MOSFETs due to their bipolar transistor structure, which involves charge carrier recombination, resulting in increased switching losses. MOSFETs, especially those based on silicon carbide (SiC) or gallium nitride (GaN), offer faster switching speeds with lower gate drive power and reduced switching losses, making them ideal for high-frequency applications. The switching frequency of MOSFETs can reach several hundred kilohertz to megahertz, while IGBTs are generally limited to tens of kilohertz.

Voltage and Current Handling Capabilities

IGBTs (Insulated Gate Bipolar Transistors) are preferred for high-voltage applications typically above 600V due to their superior voltage blocking capability and efficient current handling in industrial motor drives and power inverters. MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) excel in low to medium voltage ranges up to 250V with faster switching speeds and lower conduction losses, making them ideal for high-frequency and low-current applications. Voltage ratings for IGBTs can reach several kilovolts, supporting higher current loads, whereas MOSFETs demonstrate better performance in applications requiring rapid switching but have limited voltage endurance compared to IGBTs.

Efficiency and Power Losses

IGBTs (Insulated Gate Bipolar Transistors) typically exhibit lower conduction losses at high voltages, making them more efficient for high-power applications above 600V. MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) feature faster switching speeds and lower switching losses, enhancing efficiency in low to medium voltage applications up to around 200V. Efficiency in power electronics depends on balancing conduction and switching losses, where MOSFETs excel in high-frequency environments and IGBTs dominate in high-voltage, high-current scenarios.

Applications in Electrical Engineering

IGBTs excel in high-power applications such as motor drives, welding machines, and renewable energy systems due to their ability to handle high voltages and currents with efficient switching. MOSFETs are preferred in low-voltage, high-frequency circuits like DC-DC converters, power supplies, and RF amplifiers owing to their fast switching speed and low conduction losses. The choice between IGBT and MOSFET hinges on specific electrical engineering requirements including switching frequency, voltage rating, and thermal performance.

Selection Criteria for IGBT vs MOSFET

When selecting between IGBTs and MOSFETs, consider switching frequency and voltage ratings; MOSFETs are ideal for high-frequency applications up to 100 kHz with voltage ratings typically below 250V, while IGBTs excel in high-voltage (above 600V) and high-current scenarios at lower switching frequencies. Thermal performance and conduction losses also influence choice, as IGBTs feature lower conduction losses at higher currents but have slower switching speeds compared to MOSFETs. Cost-effectiveness and ruggedness in harsh environments further guide selection, with IGBTs often preferred in industrial motor drives and power inverters due to robustness under high voltage and current stress.

Future Trends in Power Electronics

IGBTs are expected to dominate high-voltage, high-power applications due to their robustness and efficiency in electric vehicles and renewable energy systems, while MOSFETs will continue gaining ground in low-voltage, high-frequency scenarios like data centers and consumer electronics. Emerging wide bandgap semiconductors such as SiC and GaN are enhancing both IGBT and MOSFET performance by offering higher switching speeds, lower losses, and improved thermal management. The future of power electronics lies in hybrid modules combining IGBT and MOSFET advantages, driven by increasing demand for energy-efficient, compact, and high-reliability power conversion solutions.

Switching losses

IGBTs exhibit higher switching losses than MOSFETs due to their slower turn-off times and tail current, making MOSFETs more efficient for high-frequency switching applications.

Gate threshold voltage

IGBTs typically have a higher gate threshold voltage ranging from 4 to 7 volts compared to MOSFETs which generally have a lower gate threshold voltage between 1 to 3 volts, influencing their switching performance and drive requirements.

Safe operating area (SOA)

IGBTs have a wider Safe Operating Area (SOA) than MOSFETs, making them more reliable in high-voltage, high-current applications.

Reverse recovery time

IGBTs typically exhibit longer reverse recovery times compared to MOSFETs, impacting switching efficiency in high-frequency applications.

Thermal runaway

IGBTs are more prone to thermal runaway than MOSFETs due to their positive temperature coefficient and higher conduction losses at elevated temperatures.

Parasitic capacitance

IGBTs typically exhibit higher parasitic capacitance than MOSFETs, resulting in slower switching speeds and increased switching losses in high-frequency applications.

Saturation voltage (VCE(sat))

IGBTs typically have a higher saturation voltage (V_CE(sat)) ranging from 1.5 to 3 V compared to MOSFETs, which exhibit a lower R_DS(on) resulting in saturation voltages often below 0.5 V, making MOSFETs more efficient for low-voltage, high-frequency switching applications.

Avalanche energy rating

IGBTs typically have higher avalanche energy ratings than MOSFETs, making them more suitable for applications requiring robust energy absorption during voltage spikes.

Short-circuit withstand time

IGBTs typically have a longer short-circuit withstand time of around 10 microseconds compared to MOSFETs, which usually withstand only 1 to 3 microseconds, making IGBTs more robust for high-power applications requiring fault tolerance.

Hard-switching applications

IGBTs outperform MOSFETs in hard-switching applications due to their higher voltage handling capability, lower conduction losses at high voltages, and superior thermal stability.

IGBT vs MOSFET Infographic

njnir.com

njnir.com