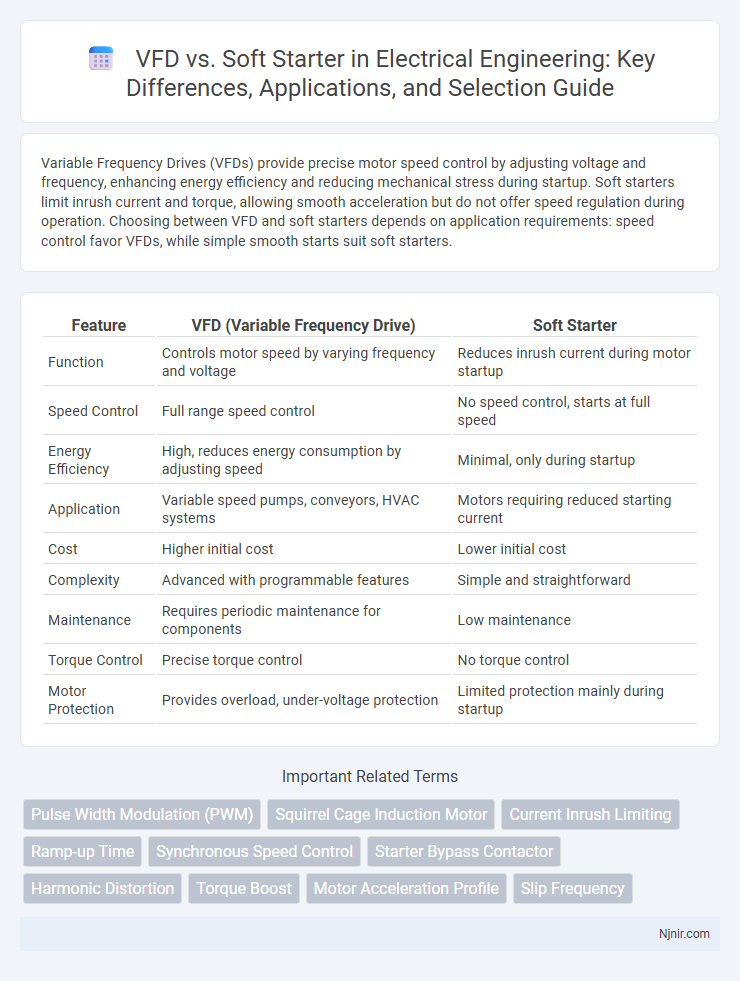

Variable Frequency Drives (VFDs) provide precise motor speed control by adjusting voltage and frequency, enhancing energy efficiency and reducing mechanical stress during startup. Soft starters limit inrush current and torque, allowing smooth acceleration but do not offer speed regulation during operation. Choosing between VFD and soft starters depends on application requirements: speed control favor VFDs, while simple smooth starts suit soft starters.

Table of Comparison

| Feature | VFD (Variable Frequency Drive) | Soft Starter |

|---|---|---|

| Function | Controls motor speed by varying frequency and voltage | Reduces inrush current during motor startup |

| Speed Control | Full range speed control | No speed control, starts at full speed |

| Energy Efficiency | High, reduces energy consumption by adjusting speed | Minimal, only during startup |

| Application | Variable speed pumps, conveyors, HVAC systems | Motors requiring reduced starting current |

| Cost | Higher initial cost | Lower initial cost |

| Complexity | Advanced with programmable features | Simple and straightforward |

| Maintenance | Requires periodic maintenance for components | Low maintenance |

| Torque Control | Precise torque control | No torque control |

| Motor Protection | Provides overload, under-voltage protection | Limited protection mainly during startup |

Introduction to VFDs and Soft Starters

Variable Frequency Drives (VFDs) control motor speed and torque by adjusting the frequency and voltage supplied to the electric motor, providing precise speed regulation and energy savings in various industrial applications. Soft Starters reduce the inrush current and mechanical stress during motor startup by gradually increasing voltage, ensuring smoother acceleration without speed control during operation. Both technologies enhance motor protection and efficiency but serve distinct roles in motor management depending on application requirements.

Fundamental Working Principles

Variable Frequency Drives (VFDs) control motor speed by varying the frequency and voltage supplied to the motor, enabling precise speed adjustments and energy savings. Soft starters limit the initial voltage to reduce inrush current and mechanical stress during motor startup without altering speed during operation. VFDs provide continuous speed control and torque optimization, whereas soft starters primarily facilitate smooth motor startup and reduce electrical and mechanical stress.

Key Differences Between VFDs and Soft Starters

Variable Frequency Drives (VFDs) control motor speed by adjusting voltage and frequency, enabling precise speed regulation and energy savings, while soft starters primarily limit inrush current during motor startup without speed control. VFDs offer full torque control and improved operational flexibility, whereas soft starters provide a simpler, cost-effective solution for reducing mechanical stress and electrical peak load during startup. The choice between VFD and soft starter depends on application needs, with VFDs suited for variable speed operations and soft starters ideal for basic starting torque management.

Motor Starting Methods: VFD vs Soft Starter

Variable Frequency Drives (VFDs) control motor speed and torque by varying the frequency and voltage, enabling smooth acceleration and deceleration with precise speed regulation. Soft starters limit the initial current and reduce mechanical stress by gradually increasing voltage during motor startup but do not control speed once running. VFDs offer enhanced energy efficiency and process control compared to soft starters, which primarily serve to reduce inrush current and mechanical wear during motor starting.

Energy Efficiency Comparison

Variable Frequency Drives (VFDs) offer superior energy efficiency by adjusting motor speed to load requirements, significantly reducing power consumption compared to Soft Starters that only limit inrush current during startup without regulating speed. VFDs can achieve energy savings of up to 50% in variable torque applications such as pumps and fans, whereas Soft Starters provide minimal efficiency gains since motors run at full speed once started. Implementing VFD technology results in lower operational costs and reduced carbon footprint, making it the preferred choice for energy-conscious industrial applications.

Application Suitability and Selection Criteria

Variable Frequency Drives (VFDs) provide precise speed control and energy savings in applications requiring variable torque, such as conveyors, pumps, and fans, whereas Soft Starters are ideal for limiting inrush current and mechanical stress during motor startup in applications like compressors and crushers. Selection criteria include load type, control complexity, energy efficiency goals, and cost considerations; VFDs offer superior performance in dynamic process control, while Soft Starters are cost-effective for simple start/stop operations. Evaluate operational requirements, desired motor protection level, and long-term maintenance to determine the optimum solution for specific industrial environments.

Impact on Motor Life and Performance

Variable Frequency Drives (VFDs) enhance motor life by providing precise speed control, reducing mechanical stress through smooth acceleration and deceleration, and improving energy efficiency under varying loads. Soft starters limit inrush current during startup, minimizing electrical stress but offer less control over motor speed and torque, which can lead to less optimized performance and potential wear during operation. VFDs deliver superior motor protection and prolonged operational lifespan by adapting to dynamic load demands, whereas soft starters primarily protect the motor during initial startup phases.

Installation, Maintenance, and Costs

Variable Frequency Drives (VFDs) typically require more complex installation involving wiring and programming compared to soft starters, which are simpler to install with fewer components. Maintenance for VFDs involves periodic checks on cooling systems and firmware updates, while soft starters demand less frequent maintenance due to fewer electronic parts. Although VFDs have higher upfront costs and maintenance expenses, they offer energy savings and precise motor control, whereas soft starters are more cost-effective initially but lack speed control features.

Harmonics and Power Quality Considerations

Variable Frequency Drives (VFDs) and soft starters influence harmonics and power quality differently due to their operational principles. VFDs often generate harmonic distortion caused by their pulse width modulation (PWM) switching, impacting total harmonic distortion (THD) levels and requiring filters or reactors for mitigation. In contrast, soft starters produce minimal harmonics since they control voltage during motor startup without altering output frequency, thereby preserving better power quality and reducing electrical noise issues.

Conclusion: Choosing the Right Solution

Selecting the right motor control solution depends on application-specific needs such as speed control, energy efficiency, and cost. Variable Frequency Drives (VFDs) offer precise speed regulation and energy savings for processes requiring variable speeds, while Soft Starters provide simple, cost-effective motor protection by reducing inrush current during startup. Evaluating operational requirements and total cost of ownership ensures the best match between VFDs and Soft Starters for optimal performance and longevity.

Pulse Width Modulation (PWM)

Pulse Width Modulation (PWM) in Variable Frequency Drives (VFDs) delivers precise motor speed control and energy efficiency, outperforming Soft Starters which primarily reduce inrush current without speed modulation.

Squirrel Cage Induction Motor

A Variable Frequency Drive (VFD) precisely controls the speed and torque of a Squirrel Cage Induction Motor by varying frequency and voltage, while a Soft Starter reduces inrush current and mechanical stress during startup without speed control.

Current Inrush Limiting

Variable Frequency Drives (VFDs provide precise current inrush limiting by gradually ramping voltage and frequency, whereas Soft Starters reduce current inrush by controlling voltage during motor startup without frequency adjustment.

Ramp-up Time

VFDs offer precise, adjustable ramp-up times for smooth motor acceleration, while soft starters provide fixed, less flexible ramp-up durations primarily designed to reduce startup current.

Synchronous Speed Control

Variable Frequency Drives (VFDs provide precise synchronous speed control by adjusting motor frequency, while Soft Starters only manage voltage during startup without altering motor speed.

Starter Bypass Contactor

The starter bypass contactor in soft starters improves energy efficiency by reducing heat loss during motor startup, unlike VFDs which control speed electronically without needing a bypass contactor.

Harmonic Distortion

Variable Frequency Drives (VFDs) typically generate higher harmonic distortion compared to Soft Starters due to their switching frequency and power electronic components.

Torque Boost

Variable Frequency Drives (VFDs) provide adjustable torque boost by controlling motor speed and frequency, while soft starters offer limited torque boost primarily during startup by gradually ramping voltage.

Motor Acceleration Profile

Variable Frequency Drives (VFDs) provide precise motor acceleration profiles by adjusting frequency and voltage for smooth ramp-up, while Soft Starters offer limited acceleration control by primarily reducing initial voltage to limit inrush current.

Slip Frequency

Slip frequency in VFDs precisely controls motor speed by adjusting frequency, whereas soft starters bypass frequency variation and only reduce voltage during startup to limit inrush current.

VFD vs Soft Starter Infographic

njnir.com

njnir.com