AC braking uses alternating current to create a magnetic field that opposes the rotor's rotation, providing smooth deceleration without mechanical wear. DC braking applies direct current to the stator windings, producing a stationary magnetic field that rapidly stops the motor by generating torque opposite to the rotor's motion. AC braking is preferred for controlled, gentle stops, while DC braking is more effective for quick, immediate halts in electric motors.

Table of Comparison

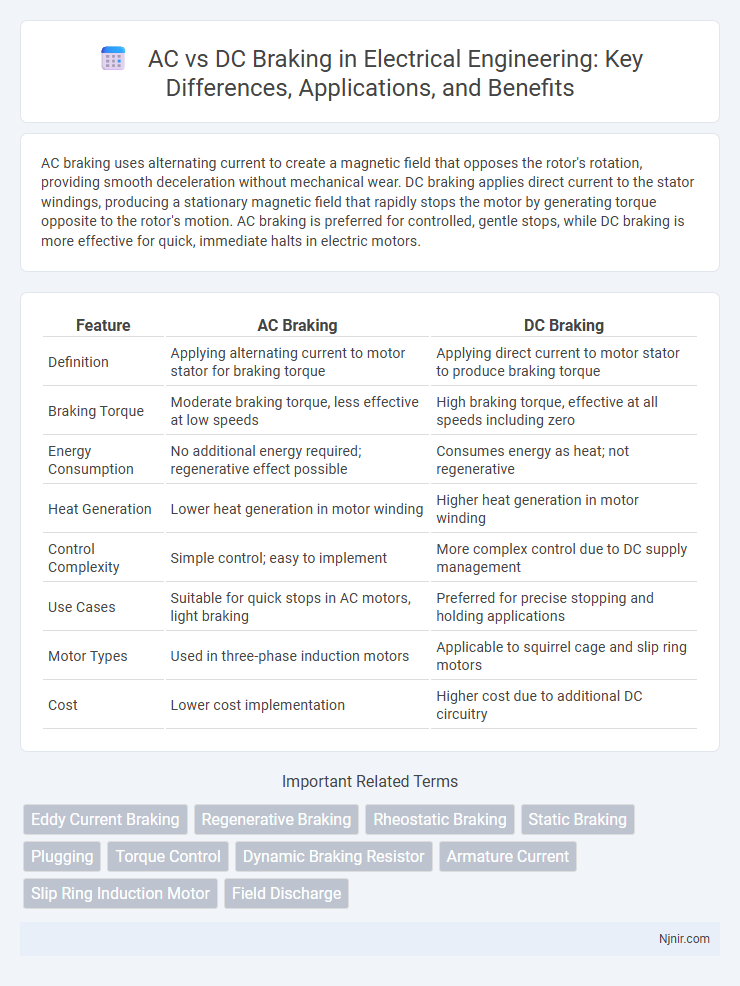

| Feature | AC Braking | DC Braking |

|---|---|---|

| Definition | Applying alternating current to motor stator for braking torque | Applying direct current to motor stator to produce braking torque |

| Braking Torque | Moderate braking torque, less effective at low speeds | High braking torque, effective at all speeds including zero |

| Energy Consumption | No additional energy required; regenerative effect possible | Consumes energy as heat; not regenerative |

| Heat Generation | Lower heat generation in motor winding | Higher heat generation in motor winding |

| Control Complexity | Simple control; easy to implement | More complex control due to DC supply management |

| Use Cases | Suitable for quick stops in AC motors, light braking | Preferred for precise stopping and holding applications |

| Motor Types | Used in three-phase induction motors | Applicable to squirrel cage and slip ring motors |

| Cost | Lower cost implementation | Higher cost due to additional DC circuitry |

Introduction to Braking Methods in Electrical Engineering

AC and DC braking are essential methods in electrical engineering used to decelerate electric motors efficiently. AC braking applies an alternating current to create a reverse magnetic field that slows the motor, while DC braking injects direct current to produce a stationary magnetic field opposing rotor motion. Understanding these braking techniques is crucial for optimizing motor control, ensuring safety, and improving system response in industrial applications.

Fundamentals of AC Braking

AC braking uses alternating current injected into the stator winding of an induction motor to create a stationary magnetic field, producing a braking torque that slows the rotor. This method dissipates kinetic energy by opposing rotor motion through electromagnetic forces without mechanical contact. AC braking is effective for quickly stopping motors while minimizing wear and providing controlled deceleration.

Fundamentals of DC Braking

DC braking involves applying direct current to the stator windings of an AC induction motor, creating a stationary magnetic field that opposes the rotor's rotation, thereby rapidly decelerating the motor. This method improves stopping accuracy and reduces mechanical wear compared to relying on natural coast-down or AC braking alone. The fundamental principle relies on the conversion of the motor into a DC-excited braking generator, providing controlled torque opposite to the direction of rotation.

Working Principles: AC vs DC Braking

AC braking operates by applying an alternating current to the stator winding of an induction motor, producing a stationary magnetic field that opposes the rotor's motion, effectively slowing it down. DC braking works by injecting direct current into the stator windings, creating a constant magnetic field that induces a counter torque on the rotor, rapidly reducing its speed. Both methods convert the motor into a generator momentarily, but AC braking offers smoother deceleration while DC braking provides a quicker, more controlled stop.

System Components and Circuit Design

AC braking systems primarily consist of a braking resistor, contactor, and control unit that injects an alternating current into the motor windings to create a opposing magnetic field. DC braking involves components such as a DC injection braking unit, resistor, and contactor to supply direct current to the motor, generating a static magnetic field for rapid deceleration. Circuit design for AC braking requires precise synchronization with the motor frequency, while DC braking circuitry emphasizes controlled current injection to avoid overheating and ensure effective torque application.

Performance Comparison: Efficiency and Response Time

DC braking offers higher efficiency in dissipating kinetic energy quickly compared to AC braking, resulting in faster response times and more precise stopping control. AC braking is generally less efficient due to the alternating nature of current, which causes slower deceleration and increased energy loss. Performance evaluation shows DC braking excels in applications requiring rapid and controlled stopping, while AC braking suits simpler, less time-critical systems.

Application Areas and Use Cases

AC braking is widely used in industrial conveyor systems and cranes due to its ability to provide smooth deceleration and precise control, enhancing safety and operational efficiency. DC braking finds frequent application in elevators, hoists, and heavy machinery where rapid and reliable stopping is critical for load protection and operator safety. Both methods are essential in manufacturing automation, with AC braking preferred for continuous processes and DC braking suited for quick stops in emergency or high-torque situations.

Safety Considerations and Protections

AC braking offers enhanced safety through controlled deceleration using alternating current, reducing the risk of mechanical wear and sudden stops. DC braking provides precise torque application to quickly halt machinery, minimizing the chance of hazardous overshoot or slippage. Both methods require integrated protection features such as thermal overload relays and short-circuit protection to ensure operator and equipment safety during the braking process.

Advantages and Limitations of Each Method

AC braking offers smooth deceleration and reduced mechanical stress by applying alternating current to the motor windings, making it ideal for applications requiring controlled stopping and energy efficiency. However, its effectiveness decreases with motor speed reduction, limiting braking torque at low speeds and causing longer stopping times. DC braking provides higher braking torque at low speeds by injecting direct current into the stator, ensuring quicker stops, but it generates more heat, increasing wear on motor components and requiring careful thermal management.

Selection Criteria for AC or DC Braking Systems

Selection criteria for AC or DC braking systems depend on the motor type, braking torque requirements, and application speed. AC braking suits applications needing rapid deceleration with variable frequency drives, while DC braking offers precise control for standard induction motors by injecting DC current into the stator winding. Factors like motor size, thermal capacity, braking duration, and cost efficiency dictate the optimal braking system choice.

Eddy Current Braking

Eddy current braking, a form of AC braking, uses electromagnetic induction to produce resistive forces without physical contact, providing smooth, wear-free slowing of electric motors.

Regenerative Braking

Regenerative braking in DC systems efficiently converts kinetic energy into electrical energy for battery storage, while AC regenerative braking primarily dissipates energy as heat due to limited energy recovery capability.

Rheostatic Braking

Rheostatic braking in DC systems dissipates kinetic energy as heat through resistors, providing precise speed control and effective deceleration compared to AC braking methods.

Static Braking

Static braking in AC and DC motors involves applying a stationary magnetic field to rapidly reduce rotor speed without mechanical wear or energy loss.

Plugging

Plugging braking in electric motors rapidly reverses the current to create a counter torque, providing quick deceleration but causing higher energy loss and mechanical stress compared to AC and DC braking methods.

Torque Control

DC braking provides precise torque control by generating a steady magnetic field, whereas AC braking offers less accurate torque modulation due to fluctuating current characteristics.

Dynamic Braking Resistor

Dynamic braking resistor in DC braking dissipates kinetic energy as heat, enabling rapid deceleration and protecting motor components compared to AC braking methods.

Armature Current

AC braking rapidly reduces armature current by applying alternating voltage, while DC braking maintains a steady armature current to create a consistent braking torque.

Slip Ring Induction Motor

Slip ring induction motors utilize DC braking by injecting direct current into the rotor windings to create a stationary magnetic field that rapidly stops the rotor, whereas AC braking involves applying AC voltage to the stator to produce a braking torque but is less effective for quick stops.

Field Discharge

AC braking rapidly dissipates energy by inducing current in the stator windings to oppose rotation, while DC braking achieves field discharge by applying direct current to the motor's field winding, creating a stationary magnetic field that efficiently stops the rotor.

AC vs DC Braking Infographic

njnir.com

njnir.com