Open loop control systems operate without feedback, making them simpler but less accurate in responding to disturbances or changes in system dynamics. Closed loop control systems use feedback to continuously monitor and adjust the output, resulting in higher precision and stability under varying conditions. The choice between open and closed loop control depends on factors such as system complexity, desired accuracy, and environmental variability.

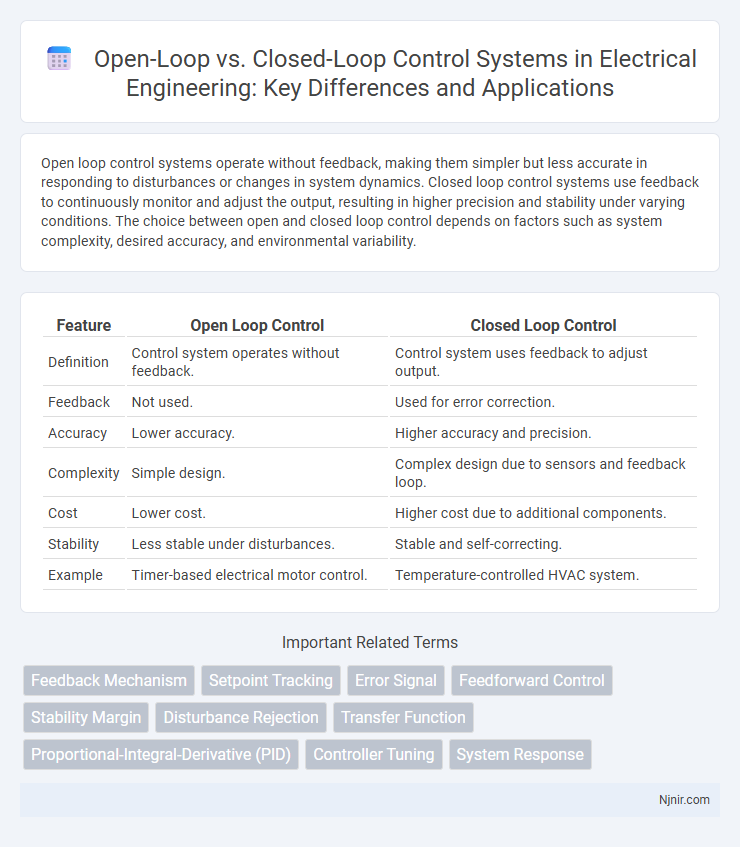

Table of Comparison

| Feature | Open Loop Control | Closed Loop Control |

|---|---|---|

| Definition | Control system operates without feedback. | Control system uses feedback to adjust output. |

| Feedback | Not used. | Used for error correction. |

| Accuracy | Lower accuracy. | Higher accuracy and precision. |

| Complexity | Simple design. | Complex design due to sensors and feedback loop. |

| Cost | Lower cost. | Higher cost due to additional components. |

| Stability | Less stable under disturbances. | Stable and self-correcting. |

| Example | Timer-based electrical motor control. | Temperature-controlled HVAC system. |

Introduction to Control Systems in Electrical Engineering

Open loop control systems operate without feedback, relying solely on input commands to influence the output, making them simpler and cost-effective but less accurate. Closed loop control systems use feedback sensors to constantly monitor output, comparing it with the desired input to adjust performance dynamically, improving precision and stability. In electrical engineering, understanding the differences between these systems is fundamental for designing efficient controllers in applications like motor drives, robotics, and power electronics.

Fundamentals of Open Loop Control

Open loop control operates without feedback, using predefined inputs to drive system outputs based on a fixed control strategy, which simplifies design and reduces cost but limits accuracy and adaptability. The fundamental components include a controller, an actuator, and a controlled process, where the controller sends control signals to the actuator to influence system behavior without measuring output. Common applications of open loop control appear in systems like washing machines and lighting controls where precise feedback is unnecessary.

Fundamentals of Closed Loop Control

Closed loop control systems use feedback to continuously compare the output with the desired setpoint, allowing automatic correction of deviations. Sensors detect system performance, sending real-time data to the controller, which adjusts inputs to maintain accuracy and stability. This feedback mechanism enhances precision, reduces errors, and compensates for disturbances, making closed loop control essential in automation and robotics.

Key Differences Between Open and Closed Loop Systems

Open loop control systems operate without feedback, executing predetermined instructions regardless of output conditions, which limits their accuracy in dynamic environments. Closed loop control systems continuously monitor output through feedback sensors, enabling automatic adjustments to maintain desired performance and enhance precision. The key difference lies in feedback utilization: closed loop systems adapt in real time, while open loop systems follow fixed inputs without correction.

Advantages of Open Loop Control

Open loop control systems offer simplicity and cost-effectiveness due to their straightforward design that does not require feedback mechanisms. They are ideal for applications where the relationship between input and output is well-defined and disturbances are minimal, ensuring reliable performance without the complexity of monitoring output. These systems also exhibit faster response times since they operate without waiting for feedback signals, making them suitable for processes with predictable conditions.

Advantages of Closed Loop Control

Closed loop control systems offer enhanced accuracy and stability by continuously monitoring output and adjusting inputs based on feedback, reducing errors caused by disturbances or system variations. They provide superior adaptability to changing environmental conditions and system parameters, ensuring consistent performance. This type of control is essential in applications requiring precise regulation, such as robotics, temperature control, and automated manufacturing processes.

Limitations and Challenges of Open Loop Systems

Open loop control systems face significant limitations due to their inability to adjust based on output feedback, resulting in decreased accuracy and increased sensitivity to disturbances. These systems cannot compensate for external changes or system variations, often leading to cumulative errors over time. Their challenges include poor adaptability and the risk of instability in dynamic or unpredictable environments.

Limitations and Challenges of Closed Loop Systems

Closed loop control systems face challenges such as increased complexity and higher costs due to the need for sensors and feedback mechanisms. These systems are limited by sensor accuracy, which can introduce errors or delays in the feedback signal, affecting system stability and responsiveness. Environmental disturbances and noise can degrade performance, requiring robust filtering and tuning to maintain precise control.

Applications of Open and Closed Loop Control in Electrical Engineering

Open loop control systems are commonly applied in electrical engineering for simple processes like lighting control and basic motor operations where feedback is not essential for performance. Closed loop control is prevalent in precision applications such as robotics, servo motors, and power electronics where sensors provide real-time feedback to adjust voltage, current, or speed for optimal accuracy and stability. Key examples include temperature regulation in HVAC systems and automatic voltage regulation in power generation, demonstrating the importance of feedback-driven control for maintaining desired electrical parameters.

Criteria for Selection: Choosing Between Open and Closed Loop Systems

Selecting between open and closed loop control systems depends on factors such as accuracy requirements, system complexity, and environmental variability. Open loop systems suit simple, low-cost applications where feedback is unnecessary, while closed loop systems excel in environments needing precise control and dynamic adjustment through continuous feedback. Evaluating system stability, response time, and cost constraints helps determine the most effective control strategy.

Feedback Mechanism

Closed loop control systems utilize continuous feedback mechanisms to automatically adjust and maintain desired output, unlike open loop systems that operate without feedback.

Setpoint Tracking

Closed loop control systems achieve precise setpoint tracking by continuously comparing output feedback to the desired setpoint, while open loop systems lack this feedback mechanism and cannot correct deviations.

Error Signal

Open loop control operates without using an error signal for feedback, whereas closed loop control continuously monitors and adjusts outputs based on the error signal to maintain desired performance.

Feedforward Control

Feedforward control in open loop systems anticipates disturbances and adjusts inputs without feedback, enhancing response speed but lacking error correction inherent in closed loop control.

Stability Margin

Closed loop control systems exhibit greater stability margins than open loop systems due to feedback mechanisms that continually adjust output to maintain desired performance.

Disturbance Rejection

Closed loop control systems effectively reject disturbances by continuously monitoring output and adjusting inputs, while open loop systems lack this feedback mechanism, making them less capable of disturbance rejection.

Transfer Function

Open loop control uses a fixed transfer function without feedback, while closed loop control incorporates a transfer function with feedback to continuously adjust system output.

Proportional-Integral-Derivative (PID)

Proportional-Integral-Derivative (PID) control excels in closed-loop systems by continuously adjusting outputs based on feedback, unlike open-loop control which operates without real-time error correction.

Controller Tuning

Open loop control requires manual controller tuning based on system modeling, while closed loop control optimizes tuning continually using real-time feedback to enhance accuracy and stability.

System Response

Open loop control systems operate without feedback, resulting in less accurate system response, while closed loop control systems continuously adjust based on feedback, ensuring precise and stable system response.

Open vs Closed Loop Control Infographic

njnir.com

njnir.com