Lap winding offers multiple parallel paths, making it suitable for low-voltage, high-current applications due to its excellent current-carrying capacity and efficient heat dissipation. Wave winding, characterized by fewer parallel paths, is ideal for high-voltage, low-current generators, providing better voltage generation and smooth commutation. The choice between lap and wave winding depends on the machine's voltage and current requirements, influencing performance and efficiency.

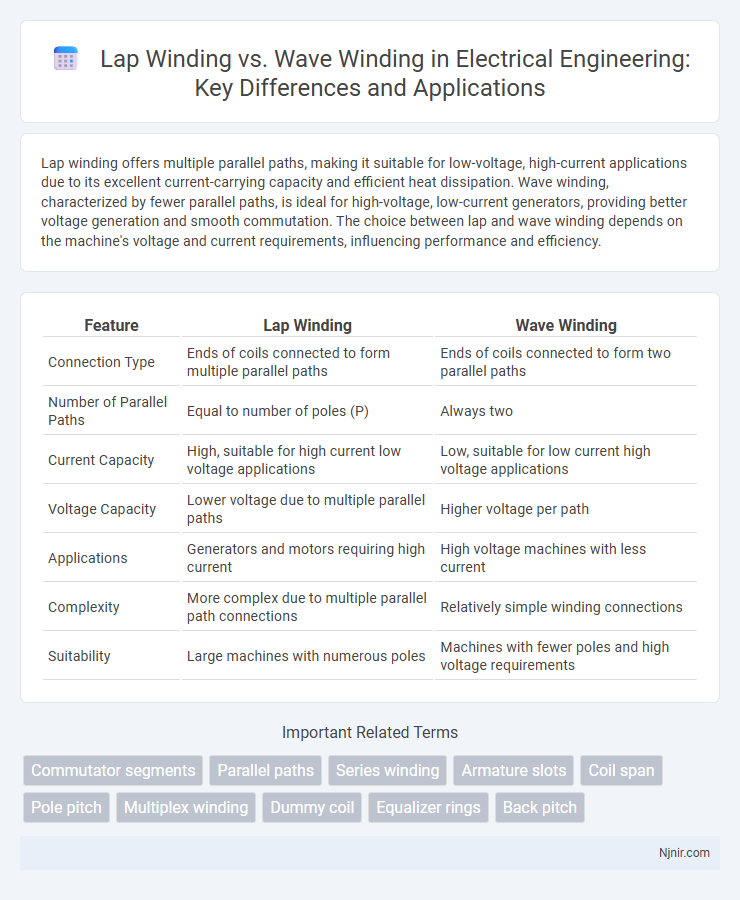

Table of Comparison

| Feature | Lap Winding | Wave Winding |

|---|---|---|

| Connection Type | Ends of coils connected to form multiple parallel paths | Ends of coils connected to form two parallel paths |

| Number of Parallel Paths | Equal to number of poles (P) | Always two |

| Current Capacity | High, suitable for high current low voltage applications | Low, suitable for low current high voltage applications |

| Voltage Capacity | Lower voltage due to multiple parallel paths | Higher voltage per path |

| Applications | Generators and motors requiring high current | High voltage machines with less current |

| Complexity | More complex due to multiple parallel path connections | Relatively simple winding connections |

| Suitability | Large machines with numerous poles | Machines with fewer poles and high voltage requirements |

Introduction to Armature Windings

Armature windings in electric machines are crucial for converting mechanical energy to electrical energy or vice versa, with Lap winding and Wave winding being the two primary types. Lap winding features multiple parallel paths proportional to the number of poles, providing high current and low voltage output ideal for heavy-duty DC machines. Wave winding, by contrast, has only two parallel paths regardless of the number of poles, which produces high voltage and low current output suitable for high voltage, low current applications.

Overview of Lap Winding

Lap winding features coils overlapping in successive electrical phases, creating multiple parallel paths for current, which results in lower current per path and improved handling of high current loads. It is commonly used in DC machines and synchronous motors with a high number of poles to enhance current distribution and winding durability. The lap winding design supports efficient commutation and reduces voltage drop, making it ideal for large, high-power applications.

Overview of Wave Winding

Wave winding, commonly used in DC machines, features a winding layout where coils are connected in series and spread around the armature in a wave-like pattern, providing fewer parallel paths compared to lap winding. This configuration allows wave winding to handle higher voltages and is ideal for applications requiring high voltage, low current output. Its design improves commutation and reduces sparking, enhancing the machine's operational efficiency and durability.

Construction Differences

Lap winding features multiple parallel paths with coils connected to adjacent slots, forming a compact build ideal for low voltage, high current applications. Wave winding has coils connected in a wave-like pattern, spanning the entire armature circumference, suitable for high voltage, low current machines. The structural distinction lies in lap winding's overlapping coil edges versus wave winding's continuous coil progression around the armature.

Working Principles

Lap winding operates by overlapping coil sides and connecting them in series to form multiple parallel paths, enhancing current capacity and enabling efficient power distribution in DC machines. Wave winding arranges coils in a manner that the winding progresses longitudinally around the armature, creating just two parallel paths regardless of armature size, which is ideal for high-voltage, low-current applications. The core working principle of lap winding emphasizes parallel path multiplication for high current, whereas wave winding focuses on voltage generation through continuous coil progression.

Applications and Suitability

Lap winding is ideal for low-voltage, high-current applications such as traction motors and DC generators, where multiple parallel paths are necessary to handle heavy loads efficiently. Wave winding suits high-voltage, low-current scenarios like large alternators and synchronous machines, offering fewer parallel paths but better voltage generation and smoother commutation. Both windings are selected based on machine size and electrical requirements, with lap winding favored in small to medium machines and wave winding commonly used in large, high-voltage equipment.

Advantages of Lap Winding

Lap winding provides superior current carrying capacity and is ideal for low voltage, high current applications due to its parallel paths that reduce resistance and heat generation. Its robust design ensures better mechanical strength and easier maintenance, making it suitable for heavy-duty motors and generators. The multiple parallel circuits in lap winding also enhance reliability and improve fault tolerance compared to wave winding.

Advantages of Wave Winding

Wave winding offers superior voltage output and reduced end coil length, enhancing efficiency and compactness in electrical machines. It provides better distribution of current, minimizing copper losses and improving heat dissipation for increased reliability. This winding type is especially beneficial in high-voltage applications due to its ability to maintain consistent electromotive force and robustness under load.

Key Differences: Lap vs Wave Winding

Lap winding features multiple parallel paths making it ideal for low voltage, high current applications, while wave winding has fewer parallel paths suited for high voltage, low current use. Lap winding coils overlap each other around the armature, providing better current distribution and fault tolerance, whereas wave winding coils are connected in series to produce higher voltage. The structural complexity of wave winding increases manufacturing costs compared to the simpler lap winding design.

Selection Criteria for Electrical Machines

Lap winding offers low voltage and high current characteristics, making it suitable for machines requiring high starting torque and low speed, such as DC motors and generators. Wave winding provides high voltage and low current output, preferred in applications demanding high-speed operation and efficient voltage regulation, like alternators. Selection depends on machine rating, desired voltage and current levels, starting torque, and speed requirements to optimize performance and ensure reliable operation.

Commutator segments

Lap winding features multiple parallel current paths with each commutator segment connected to two coil sides for high current output, while wave winding has fewer parallel paths with each segment linked to coil sides spaced further apart, optimizing voltage and commutator durability.

Parallel paths

Lap winding features multiple parallel paths equal to the number of poles, enhancing current capacity, while wave winding has only two parallel paths regardless of poles, optimizing for higher voltage output.

Series winding

Lap winding features multiple parallel paths ideal for high current low voltage applications, while wave winding provides fewer parallel paths suited for high voltage low current, with series winding configurations enhancing torque by connecting coils in a single path.

Armature slots

Lap winding features armature slots connected to multiple parallel paths enhancing current capacity, whereas wave winding uses armature slots arranged to form fewer parallel paths, optimizing voltage output.

Coil span

Lap winding features a coil span typically equal to the pole pitch for better short-circuit current handling, while wave winding uses a coil span slightly larger than the pole pitch to achieve longer electrical paths and higher voltage generation.

Pole pitch

Lap winding features a pole pitch equal to one, optimizing short-pitched coils for machines with a large number of poles, while wave winding uses a pole pitch of two or more, enabling long-pitched coils suitable for machines with fewer poles and higher voltage.

Multiplex winding

Multiplex wave winding, unlike traditional lap winding, enables multiple parallel paths in armature coils, enhancing current-carrying capacity and reducing commutator wear in DC machines.

Dummy coil

Dummy coils in lap winding improve coil distribution uniformity without contributing to output, whereas wave winding typically avoids dummy coils by maintaining continuous coil progression.

Equalizer rings

Lap winding utilizes equalizer rings to balance current distribution across parallel paths, whereas wave winding typically employs commutator segments without equalizer rings due to its series connection of coils.

Back pitch

Lap winding features a back pitch shorter than the pole pitch, enhancing parallel paths and current capacity, while wave winding has a back pitch equal to or greater than the pole pitch, enabling fewer parallel paths and higher voltage output.

Lap winding vs Wave winding Infographic

njnir.com

njnir.com