Air core inductors offer low core losses and high-frequency performance, making them ideal for RF applications, while iron core inductors provide higher inductance and magnetic flux density, suitable for power transformers and low-frequency circuits. Iron cores enhance inductance by concentrating magnetic fields but suffer from hysteresis and eddy current losses, which air cores avoid due to the absence of ferromagnetic materials. Choosing between air core and iron core depends on application frequency, efficiency requirements, and size constraints.

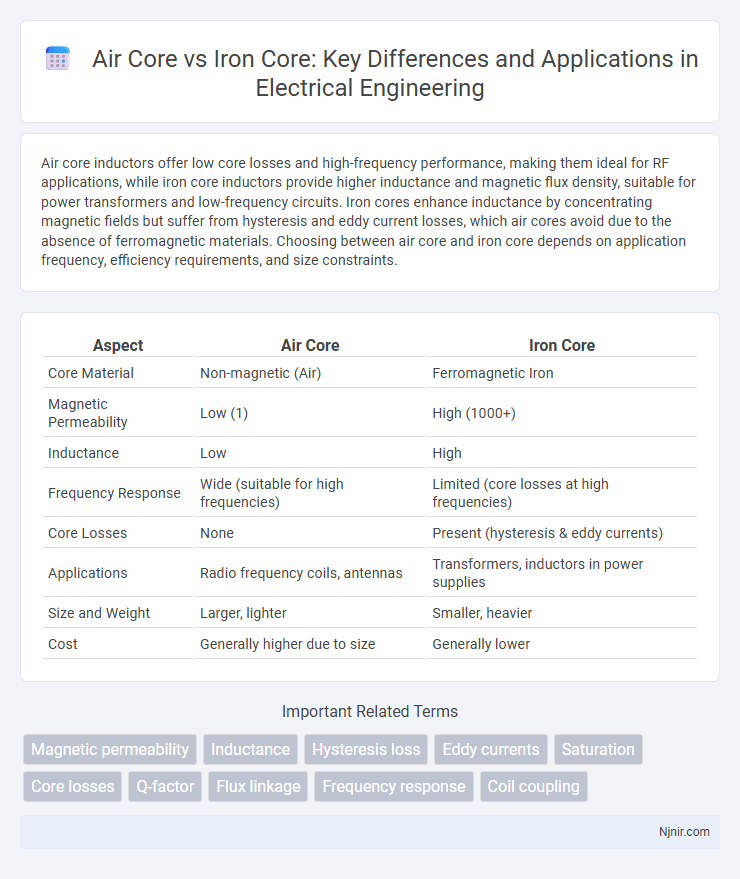

Table of Comparison

| Aspect | Air Core | Iron Core |

|---|---|---|

| Core Material | Non-magnetic (Air) | Ferromagnetic Iron |

| Magnetic Permeability | Low (1) | High (1000+) |

| Inductance | Low | High |

| Frequency Response | Wide (suitable for high frequencies) | Limited (core losses at high frequencies) |

| Core Losses | None | Present (hysteresis & eddy currents) |

| Applications | Radio frequency coils, antennas | Transformers, inductors in power supplies |

| Size and Weight | Larger, lighter | Smaller, heavier |

| Cost | Generally higher due to size | Generally lower |

Introduction to Air Core and Iron Core

Air core inductors use a non-magnetic center, resulting in minimal core losses and high-frequency performance, making them ideal for RF circuits and applications requiring low inductance values. Iron core inductors incorporate a ferromagnetic core, which significantly increases inductance and magnetic field strength but introduces core losses and saturation risks, commonly utilized in power transformers and low-frequency applications. The choice between air core and iron core depends on frequency range, inductance requirements, and efficiency considerations in electronic design.

Fundamental Differences Between Air Core and Iron Core

Air core inductors use non-magnetic materials, resulting in low inductance and minimal core losses, making them ideal for high-frequency applications. Iron core inductors feature a magnetic core, significantly increasing inductance and energy storage capacity but introducing core losses and potential saturation under high currents. The fundamental difference lies in their core material, directly affecting magnetic permeability, energy efficiency, and frequency response.

Magnetic Field Characteristics

Air core coils produce a magnetic field with minimal core losses and no magnetic saturation, resulting in a linear inductance response ideal for high-frequency applications. Iron core coils generate a stronger magnetic field due to the high permeability of iron, significantly increasing inductance but introducing hysteresis and eddy current losses. The magnetic field in iron core inductors is more concentrated and stable under varying currents, making them suitable for low-frequency, high-power environments.

Efficiency and Energy Losses

Air core inductors exhibit higher efficiency due to the absence of magnetic core losses such as hysteresis and eddy currents that are prevalent in iron core inductors. Iron core inductors provide higher inductance values but suffer from increased energy losses, especially at higher frequencies, due to core saturation and magnetic hysteresis. The lower energy losses in air core inductors make them preferable in high-frequency applications where efficiency is critical.

Frequency Response and Applications

Air core inductors exhibit superior frequency response by minimizing core losses and avoiding magnetic saturation, making them ideal for high-frequency applications such as RF circuits and audio signal processing. Iron core inductors provide higher inductance values and better magnetic coupling but suffer from core losses and limited high-frequency performance, which confines their use to low-frequency power supplies and transformers. Selecting between air core and iron core depends on balancing frequency requirements with inductance strength and application-specific efficiency.

Weight and Size Considerations

Air core inductors are significantly lighter and smaller than iron core inductors due to the absence of a heavy magnetic core, making them ideal for applications where weight and compactness are critical. Iron core inductors tend to be bulkier and heavier because the iron core provides increased magnetic permeability, which enhances inductance but adds to the overall size and mass. Designers often select air core inductors in high-frequency circuits to minimize weight and size while sacrificing some inductance efficiency.

Cost Comparison

Air core inductors typically have higher manufacturing costs due to the need for more turns of wire and larger physical size to achieve comparable inductance values, whereas iron core inductors benefit from the magnetic properties of the core material, allowing for smaller, less expensive coils. Iron core inductors are generally more cost-effective for high inductance applications, as the iron core significantly reduces the required wire length and overall material usage. The cost efficiency of iron core inductors makes them preferable in mass-produced electronics, while air core inductors remain favored where core losses and magnetic saturation must be minimized despite higher costs.

Thermal Performance

Air core inductors offer superior thermal performance due to the absence of a magnetic core, which eliminates core losses and heat generation under high-frequency operation. Iron core inductors typically experience increased heat buildup caused by hysteresis and eddy current losses within the iron material, limiting their efficiency and thermal stability. Effective thermal management in air core designs enables higher current handling and prolonged reliability compared to iron core counterparts.

Typical Use Cases in Electrical Engineering

Air core inductors are commonly used in high-frequency applications such as radio transmitters and filters where minimal core losses and signal distortion are critical. Iron core inductors, featuring higher inductance and magnetic permeability, are preferred in power transformers, inductors for power supplies, and audio equipment for efficient energy transfer at lower frequencies. The choice between air and iron cores depends on performance needs including frequency range, inductance stability, and thermal handling.

Selecting the Right Core for Your Application

Selecting the right core for your application depends primarily on the frequency and power requirements. Air cores are ideal for high-frequency circuits and applications needing low core losses, such as radio-frequency transformers and inductors. Iron cores excel in low-frequency, high-power applications due to their high magnetic permeability and efficiency in concentrating magnetic fields, making them suitable for power transformers and inductors in audio or power supply circuits.

Magnetic permeability

Air core coils exhibit low magnetic permeability close to that of free space (m0 1.26 x 10-6 H/m), whereas iron core coils feature significantly higher magnetic permeability (ranging from 100 to 5000 times m0), enhancing inductance and magnetic field concentration.

Inductance

Iron core inductors provide higher inductance due to their magnetic permeability, whereas air core inductors offer lower inductance but superior frequency response and reduced core losses.

Hysteresis loss

Air core inductors eliminate hysteresis loss found in iron core inductors due to the absence of a magnetic material subject to magnetic domain realignment.

Eddy currents

Air core inductors eliminate Eddy current losses common in iron core inductors due to the absence of magnetic materials, enhancing efficiency at high frequencies.

Saturation

Air core inductors avoid magnetic saturation by lacking ferromagnetic material, while iron core inductors experience saturation when their core magnetic flux density exceeds the material's saturation threshold.

Core losses

Air core inductors exhibit significantly lower core losses than iron core inductors due to the absence of magnetic hysteresis and eddy current losses.

Q-factor

Air core inductors exhibit higher Q-factors than iron core inductors due to lower core losses and reduced magnetic hysteresis.

Flux linkage

Air core inductors exhibit lower flux linkage due to the absence of a ferromagnetic core, whereas iron core inductors achieve higher flux linkage by concentrating magnetic flux within the iron core material.

Frequency response

Air core inductors offer superior high-frequency response with minimal core losses compared to iron core inductors, which exhibit better low-frequency performance but suffer from core saturation and increased losses at higher frequencies.

Coil coupling

Air core coils exhibit lower magnetic coupling and reduced inductance compared to iron core coils, which enhance magnetic flux concentration and improve coil coupling efficiency.

air core vs iron core Infographic

njnir.com

njnir.com