Flyback converters store energy in the transformer's magnetic field during the switch ON time and release it when the switch is OFF, making them ideal for low-power, isolated power supplies with simple design requirements. Forward converters transfer energy directly to the output during the switch ON time, offering higher efficiency and better regulation in medium to high-power applications but requiring more complex circuitry. Selecting between flyback and forward converters depends on power level, efficiency needs, circuit complexity, and isolation requirements.

Table of Comparison

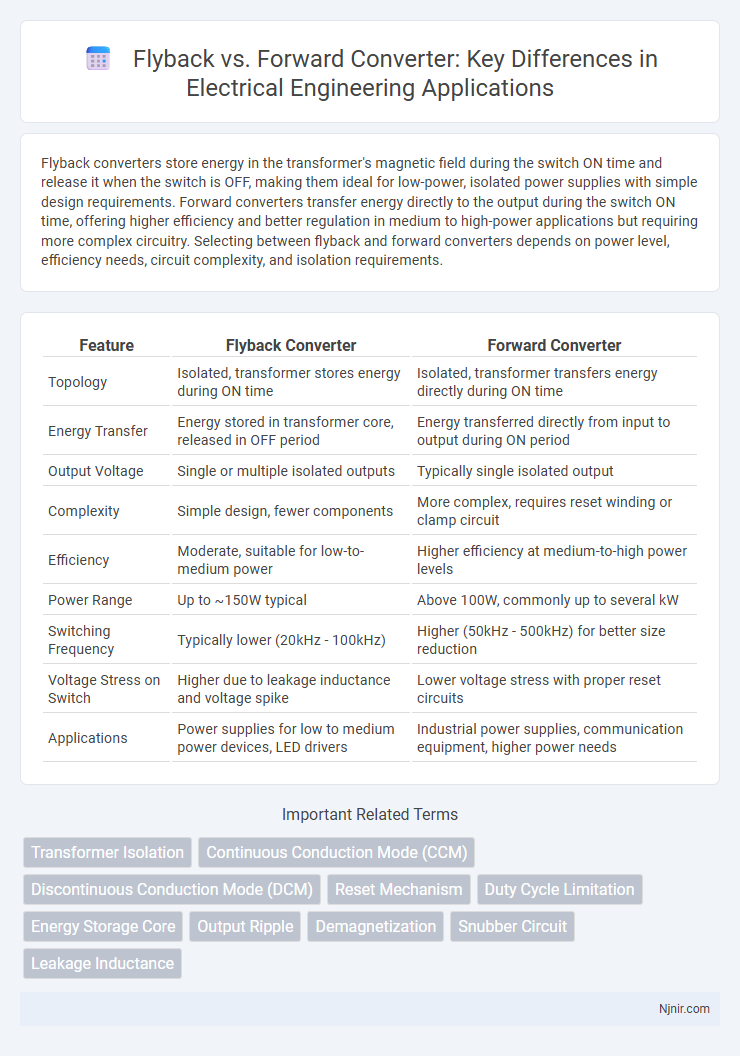

| Feature | Flyback Converter | Forward Converter |

|---|---|---|

| Topology | Isolated, transformer stores energy during ON time | Isolated, transformer transfers energy directly during ON time |

| Energy Transfer | Energy stored in transformer core, released in OFF period | Energy transferred directly from input to output during ON period |

| Output Voltage | Single or multiple isolated outputs | Typically single isolated output |

| Complexity | Simple design, fewer components | More complex, requires reset winding or clamp circuit |

| Efficiency | Moderate, suitable for low-to-medium power | Higher efficiency at medium-to-high power levels |

| Power Range | Up to ~150W typical | Above 100W, commonly up to several kW |

| Switching Frequency | Typically lower (20kHz - 100kHz) | Higher (50kHz - 500kHz) for better size reduction |

| Voltage Stress on Switch | Higher due to leakage inductance and voltage spike | Lower voltage stress with proper reset circuits |

| Applications | Power supplies for low to medium power devices, LED drivers | Industrial power supplies, communication equipment, higher power needs |

Introduction to Flyback and Forward Converters

Flyback and forward converters are widely used DC-DC switching power supply topologies essential for voltage regulation and isolation in electronic devices. The flyback converter stores energy in a transformer during the switch-on phase, releasing it to the output during switch-off, making it suitable for low to medium power applications with multiple output voltages. The forward converter transfers energy directly to the output through the transformer when the switch is on, enabling higher efficiency and power density, ideal for medium to high power applications requiring precise voltage regulation.

Working Principle of Flyback Converters

Flyback converters operate by storing energy in a transformer's magnetic field during the switch-on period and releasing it to the output during the switch-off period, enabling electrical isolation and voltage conversion. The primary switch controls current through the transformer primary winding, inducing a voltage in the secondary winding when the switch turns off. This cyclical energy transfer allows efficient, compact power supply design suitable for low to medium power applications.

Working Principle of Forward Converters

Forward converters transfer energy directly from the input to the output during the switch-on period, using a transformer to provide isolation and voltage scaling. When the switch is on, energy is delivered to the output through the transformer and an output inductor filters the current, maintaining continuous power flow. The reset winding or auxiliary circuit ensures the transformer core demagnetizes during the off period, preventing saturation and maintaining efficient operation.

Key Differences Between Flyback and Forward Converters

Flyback converters store energy in a transformer during the switch-on period and release it to the output during the switch-off period, making them suitable for low to medium power applications. Forward converters transfer energy directly to the output transformer during the switch-on interval, providing higher efficiency and better performance in medium to high power ranges. Flyback converters typically have simpler designs and require fewer components, while forward converters offer improved voltage regulation and lower output ripple.

Efficiency Comparison: Flyback vs Forward Converter

Flyback converters typically have lower efficiency than forward converters due to higher switching losses and increased stress on components caused by energy storage in the transformer during the off period. Forward converters exhibit better efficiency by transferring energy directly during the switch-on interval, reducing core losses and improving thermal performance. Efficiency rates for forward converters often exceed 85-90%, while flyback converters generally achieve 70-85% depending on power levels and design optimization.

Applications of Flyback Converters

Flyback converters are widely used in low to medium power applications such as power supplies for televisions, chargers, and industrial control systems due to their simplicity and cost-effectiveness. They are ideal for isolated power conversion where multiple output voltages or galvanic isolation is required, especially in scenarios with input voltage ranges and output power below 150 watts. Their ability to handle high voltage spikes and operate efficiently in standby mode makes them suitable for applications like LED drivers, battery chargers, and standby power supplies in consumer electronics.

Applications of Forward Converters

Forward converters are predominantly used in applications requiring efficient power conversion with moderate voltage and current levels, such as in telecommunications, industrial control systems, and computer power supplies. Their ability to provide a continuous output current with minimal ripple makes them ideal for powering sensitive electronic devices and circuits. Compared to flyback converters, forward converters excel in delivering higher power density and improved efficiency in low to medium power applications up to several hundred watts.

Advantages and Disadvantages: Flyback vs Forward

Flyback converters offer simplicity and cost-efficiency, making them ideal for low to medium power applications, but they tend to have lower efficiency and higher voltage stress on components compared to forward converters. Forward converters provide higher efficiency and continuous energy transfer, which benefits high power applications, though they require more complex circuitry and larger transformers. Choosing between flyback and forward converters depends on factors such as power level, cost constraints, and efficiency requirements.

Design Considerations for Flyback and Forward Converters

Flyback converters require careful transformer design to manage energy storage and leakage inductance, optimizing for high voltage isolation and minimizing output ripple. Forward converters demand precise control of transformer reset mechanisms and efficient magnetic core utilization to handle continuous energy transfer and reduce losses. Both topologies emphasize selection of switching frequency and duty cycle to balance efficiency, thermal performance, and electromagnetic interference (EMI) constraints.

Choosing the Right Converter for Your Application

Flyback converters are ideal for low to medium power applications requiring electrical isolation and simpler designs, commonly used in power supplies under 100W. Forward converters excel in higher power situations above 100W, offering improved efficiency and reduced electromagnetic interference due to their continuous energy transfer method. Selecting the right converter depends on power level, cost constraints, efficiency requirements, and the need for isolation in your specific application.

Transformer Isolation

Flyback converters provide transformer isolation by storing energy in the transformer during the switch-on period and releasing it during the switch-off period, while forward converters achieve transformer isolation by directly transferring energy through the transformer during the switch-on period with additional components to reset the transformer core.

Continuous Conduction Mode (CCM)

Flyback converters operate in Continuous Conduction Mode (CCM) by allowing the transformer magnetizing current to flow continuously, while forward converters maintain CCM through an inductor that continuously conducts current during both switch on and off cycles, resulting in lower current ripple and higher efficiency.

Discontinuous Conduction Mode (DCM)

Flyback converters operate efficiently in Discontinuous Conduction Mode (DCM) by storing energy in the transformer during the on-time and releasing it during the off-time, whereas forward converters in DCM exhibit reduced efficiency due to their reliance on continuous current flow through the output inductor.

Reset Mechanism

The flyback converter uses magnetic flux reset via transformer core demagnetization, while the forward converter employs an active reset winding or external circuitry to prevent core saturation.

Duty Cycle Limitation

Flyback converters have a duty cycle limitation typically below 50% due to energy storage and transfer constraints, whereas forward converters can operate with higher duty cycles, often up to 80%, allowing for greater power throughput and efficiency.

Energy Storage Core

Flyback converters store energy in the magnetic core during the switch-on period and release it during the switch-off period, while forward converters transfer energy directly to the output transformer without significant core energy storage.

Output Ripple

Flyback converters typically exhibit higher output ripple voltage compared to forward converters due to their energy storage and transfer methods in the transformer, impacting output voltage stability and filtering requirements.

Demagnetization

Flyback converters achieve demagnetization through the transformer secondary winding during the off interval, while forward converters use an additional demagnetization winding or reset mechanism to prevent core saturation.

Snubber Circuit

Flyback converters require snubber circuits to manage high-voltage spikes caused by transformer leakage inductance, whereas forward converters use snubbers primarily to protect switches from voltage transients and to improve efficiency.

Leakage Inductance

Leakage inductance in flyback converters causes higher voltage spikes and reduced efficiency compared to forward converters, which typically minimize leakage inductance through transformer design.

flyback vs forward converter Infographic

njnir.com

njnir.com