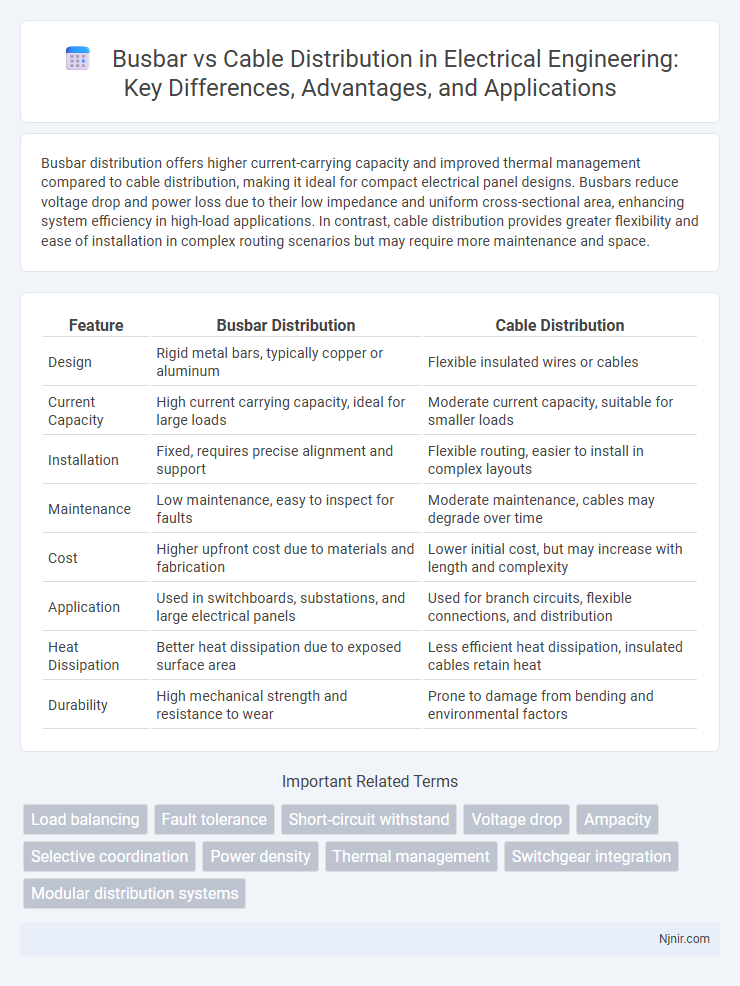

Busbar distribution offers higher current-carrying capacity and improved thermal management compared to cable distribution, making it ideal for compact electrical panel designs. Busbars reduce voltage drop and power loss due to their low impedance and uniform cross-sectional area, enhancing system efficiency in high-load applications. In contrast, cable distribution provides greater flexibility and ease of installation in complex routing scenarios but may require more maintenance and space.

Table of Comparison

| Feature | Busbar Distribution | Cable Distribution |

|---|---|---|

| Design | Rigid metal bars, typically copper or aluminum | Flexible insulated wires or cables |

| Current Capacity | High current carrying capacity, ideal for large loads | Moderate current capacity, suitable for smaller loads |

| Installation | Fixed, requires precise alignment and support | Flexible routing, easier to install in complex layouts |

| Maintenance | Low maintenance, easy to inspect for faults | Moderate maintenance, cables may degrade over time |

| Cost | Higher upfront cost due to materials and fabrication | Lower initial cost, but may increase with length and complexity |

| Application | Used in switchboards, substations, and large electrical panels | Used for branch circuits, flexible connections, and distribution |

| Heat Dissipation | Better heat dissipation due to exposed surface area | Less efficient heat dissipation, insulated cables retain heat |

| Durability | High mechanical strength and resistance to wear | Prone to damage from bending and environmental factors |

Overview of Busbar and Cable Distribution Systems

Busbar distribution systems provide a centralized, modular approach for electrical power distribution using metal strips or bars, offering high current capacity and improved heat dissipation compared to traditional cable systems. Cable distribution relies on insulated conductors that are flexible but typically occupy more space and require increased maintenance due to potential overheating and mechanical wear. In industrial and commercial settings, busbars enhance reliability and ease of installation, while cables remain prevalent for long-distance and complex routing needs.

Fundamental Differences Between Busbars and Cables

Busbars and cables serve distinct roles in electrical distribution systems, with busbars offering a rigid, flat, or tubular conductor designed for high current carrying capacity and centralized power distribution. Cables, in contrast, are insulated conductors suited for flexible routing and connecting individual devices or panels over various distances. The fundamental differences lie in their structure, current capacity, installation flexibility, and typical applications within electrical networks.

Design Considerations for Busbar Systems

Busbar systems require careful design consideration, including current-carrying capacity, thermal management, and mechanical strength to ensure efficient power distribution. Proper insulation materials and clearances must be selected to prevent short circuits and electrical faults in high-voltage applications. The modularity and compact nature of busbars facilitate easier installation and maintenance compared to traditional cable distribution systems.

Design Considerations for Cable Distribution

Design considerations for cable distribution prioritize flexibility, ease of installation, and cost-effectiveness compared to busbar systems. Proper cable sizing, insulation level, and routing are critical to minimize voltage drop, heat accumulation, and electromagnetic interference. Ensuring compliance with relevant standards such as IEC 60364 and National Electrical Code (NEC) is essential to guarantee safety, reliability, and maintainability in cable distribution networks.

Installation Procedures: Busbars vs Cables

Busbar installation involves mounting pre-fabricated metal strips or bars on insulators, requiring precise alignment and secure bolting to ensure efficient current distribution, while cable installation entails routing insulated conductive wires through conduits or trays, followed by termination with connectors or lugs. Busbars typically enable faster installation with fewer connection points and reduced labor compared to cable systems, which demand extensive handling, bending, and securing to prevent damage and maintain electrical integrity. Maintenance considerations also differ, as busbars offer easier inspection and modifications, whereas cables require careful tracing and potential re-termination during upgrades or repairs.

Efficiency and Power Loss Comparison

Busbar systems offer higher efficiency compared to cable distribution due to their lower electrical resistance and reduced heat generation, resulting in minimized power losses. Busbars enable improved current-carrying capacity and better thermal management, which significantly reduces energy dissipation during operation. In contrast, cable systems experience greater power loss from resistance and heat, making busbars a more energy-efficient choice for electrical distribution in industrial and commercial applications.

Safety Features and Risk Assessment

Busbar distribution systems enhance safety by reducing fire hazards due to their enclosed and insulated design, minimizing exposure to live electrical parts compared to traditional cables. Risk assessment highlights lower maintenance needs and easier fault identification in busbars, translating to reduced downtime and improved operational safety. Cable distribution poses higher risks from mechanical damage and insulation failure, increasing potential arc flash incidents and requiring more frequent inspections to mitigate hazards.

Cost Analysis: Busbars vs Cable Distribution

Busbar systems typically offer lower installation costs compared to cable distribution due to reduced labor and material expenses, especially in high-current applications. Cable distribution involves higher costs for cable procurement, insulation, and labor-intensive installation processes, increasing overall expenditure. Maintenance costs favor busbars as well, as they provide easier access and better heat dissipation, reducing long-term operational expenses.

Maintenance and Longevity Factors

Busbars offer enhanced maintenance efficiency due to fewer connection points and reduced risk of loose joints compared to cable distribution, which requires regular inspection of multiple cable connections prone to wear. The robust construction of busbars improves longevity by minimizing electrical resistance and heat generation, whereas cables may degrade faster under mechanical stress and environmental factors. Choosing busbars enhances system reliability and lowers long-term maintenance costs in electrical distribution networks.

Applications and Suitability in Electrical Networks

Busbar systems provide efficient power distribution in high-current industrial and commercial electrical networks, where space optimization and minimal energy loss are critical. Cable distribution remains preferred for flexible routing and lower initial installation costs in residential and small-scale applications with varied load requirements. Busbars excel in modular setups and large substations due to better heat dissipation and ease of maintenance, while cables suit complex, non-linear layouts with multiple branching points.

Load balancing

Busbar distribution systems provide superior load balancing by evenly distributing electrical current across multiple connection points, reducing voltage drops and enhancing system reliability compared to cable distribution.

Fault tolerance

Busbar distribution systems offer higher fault tolerance than cable distribution by providing multiple current paths and minimizing risk of failure during short circuits.

Short-circuit withstand

Busbars offer superior short-circuit withstand capacity compared to cables due to their robust construction and lower impedance.

Voltage drop

Busbar distribution systems typically experience significantly lower voltage drop compared to cable distribution due to their larger cross-sectional area and reduced resistance.

Ampacity

Busbars provide higher ampacity and superior heat dissipation compared to cables, enabling more efficient power distribution in compact electrical systems.

Selective coordination

Busbar distribution systems provide superior selective coordination by minimizing fault propagation and enabling precise isolation compared to traditional cable distribution methods.

Power density

Busbar distribution achieves higher power density by enabling compact, efficient current conduction and heat dissipation compared to traditional cable distribution systems.

Thermal management

Busbar distribution systems offer superior thermal management by providing lower resistance and improved heat dissipation compared to traditional cable distribution.

Switchgear integration

Busbar distribution offers enhanced switchgear integration through streamlined connections and reduced installation complexity compared to traditional cable systems.

Modular distribution systems

Modular distribution systems enhance efficiency and flexibility by using busbars for compact, scalable power distribution compared to traditional cable systems that offer less modularity and higher installation complexity.

busbar vs cable distribution Infographic

njnir.com

njnir.com