RCD and RC snubbers both serve to protect electrical circuits from voltage spikes but differ in design and function; an RCD snubber includes a diode for rapid discharge, making it ideal for inductive loads, while an RC snubber uses only a resistor and capacitor to absorb energy and smooth out transient voltages. RCD snubbers are more effective in clamping voltage spikes quickly, reducing electromagnetic interference (EMI) and improving component longevity. RC snubbers provide simpler design and cost-efficiency, suitable for less demanding applications with lower transient voltages.

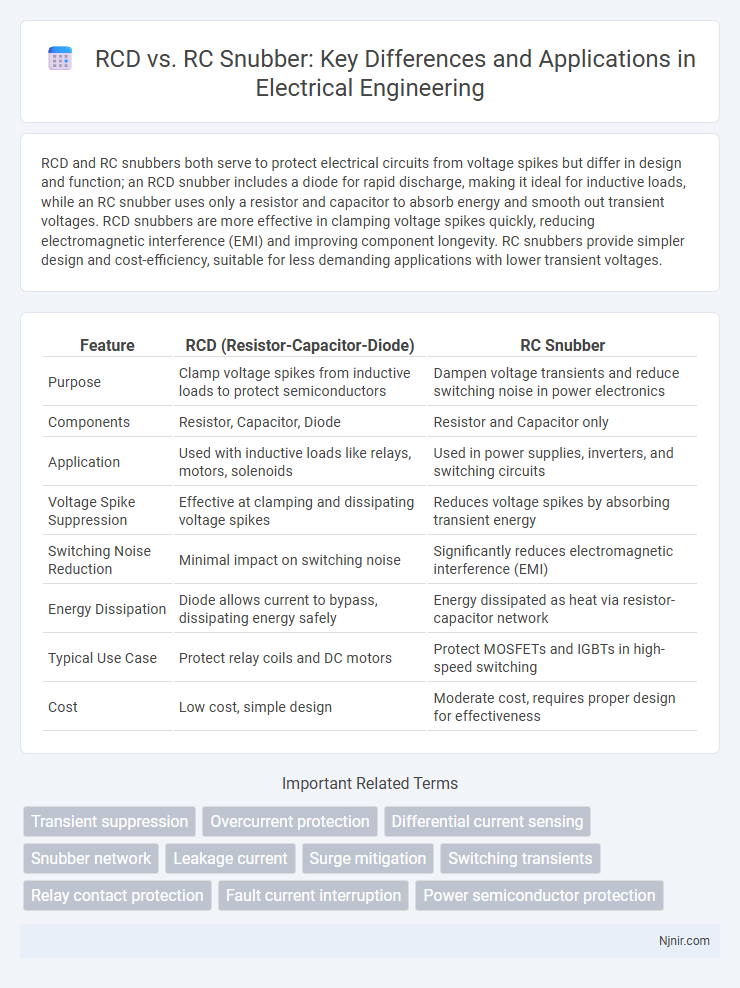

Table of Comparison

| Feature | RCD (Resistor-Capacitor-Diode) | RC Snubber |

|---|---|---|

| Purpose | Clamp voltage spikes from inductive loads to protect semiconductors | Dampen voltage transients and reduce switching noise in power electronics |

| Components | Resistor, Capacitor, Diode | Resistor and Capacitor only |

| Application | Used with inductive loads like relays, motors, solenoids | Used in power supplies, inverters, and switching circuits |

| Voltage Spike Suppression | Effective at clamping and dissipating voltage spikes | Reduces voltage spikes by absorbing transient energy |

| Switching Noise Reduction | Minimal impact on switching noise | Significantly reduces electromagnetic interference (EMI) |

| Energy Dissipation | Diode allows current to bypass, dissipating energy safely | Energy dissipated as heat via resistor-capacitor network |

| Typical Use Case | Protect relay coils and DC motors | Protect MOSFETs and IGBTs in high-speed switching |

| Cost | Low cost, simple design | Moderate cost, requires proper design for effectiveness |

Introduction to RCD and RC Snubber Circuits

RCD snubber circuits consist of a resistor, capacitor, and diode designed to protect switching devices from voltage spikes by dissipating energy stored in inductive loads. RC snubber circuits combine a resistor and capacitor to reduce voltage transients and limit the rate of voltage change (dv/dt) across semiconductor devices. Both circuits improve the reliability and longevity of power electronics by mitigating switching noise and reducing electromagnetic interference.

Fundamental Differences Between RCD and RC Snubbers

RCD snubbers utilize a resistor, capacitor, and diode to efficiently clamp voltage spikes and dissipate energy during switching events in inductive loads, preventing device damage. RC snubbers consist only of a resistor and capacitor connected across the switch, primarily attenuating voltage oscillations and reducing switching noise without the rectifying action of a diode. The fundamental difference lies in the presence of the diode in RCD snubbers, enabling controlled energy release and enhanced protection against voltage transients compared to the purely passive damping of RC snubbers.

Circuit Components and Configurations

RCD snubbers consist of a resistor, capacitor, and diode connected in series, designed to absorb voltage spikes by clamping the transient energy and dissipating it through the resistor. RC snubbers use only a resistor and capacitor in series across the switching device or transformer winding to limit voltage rise and reduce switching noise without a diode, making them simpler but less effective at energy dissipation. The diode in RCD snubbers provides a controlled path for the stored energy in the capacitor to safely discharge, enhancing protection against voltage spikes compared to the passive damping approach of RC snubbers.

Working Principles of RCD and RC Snubbers

RCD snubbers operate by using a resistor, capacitor, and diode to absorb and dissipate transient voltage spikes, protecting switching devices from voltage overshoot during turn-off events. The capacitor in the RCD snubber temporarily stores the energy from the inductive load, while the diode directs the surge current into the capacitor and resistor, which then dissipates the energy as heat. RC snubbers, composed of only a resistor and capacitor, reduce voltage spikes by providing a path for the transient energy to be absorbed and dissipated, but lack the diode's directional control, making them less effective for high-voltage switching applications compared to RCD snubbers.

Applications in Power Electronics

RCD and RC snubbers are widely utilized in power electronics to protect switching devices from voltage spikes and reduce electromagnetic interference. RCD snubbers excel in circuits with high di/dt and high voltage stress, such as inductive load switching and power converters, by dissipating excess energy through a diode and capacitor network. RC snubbers are preferred for damping high-frequency oscillations and controlling dv/dt in circuits like MOSFET and IGBT gate drives, offering improved switching performance and device longevity.

Advantages and Limitations

RCD snubbers offer simplicity and effective voltage spike suppression in inductive circuits, providing efficient energy dissipation through a resistor, capacitor, and diode combination. RC snubbers excel in controlling high-frequency switching noise and limiting dv/dt, enhancing device protection and reducing electromagnetic interference, though they may generate continuous power loss due to resistor heating. While RCD snubbers are cost-effective and easy to implement, their main limitation is slower response time compared to RC snubbers, which require careful resistor-capacitor sizing to balance performance and power dissipation.

Efficiency and Performance Considerations

RCD snubbers offer high efficiency in dissipating voltage spikes by using resistor-capacitor-diode networks to clamp transient voltages quickly, minimizing power loss in switching devices. RC snubbers, while simpler and less costly, tend to dissipate more power due to continuous energy absorption through the resistor, reducing overall system efficiency. Performance-wise, RCD snubbers provide superior protection in high-frequency switching applications by faster energy dissipation, whereas RC snubbers are better suited for lower frequency scenarios where simplicity and cost are the priority.

Design Guidelines and Selection Criteria

RCD snubber circuits, consisting of a resistor, capacitor, and diode, are designed to clamp voltage spikes and reduce switching losses in power electronics by controlling energy dissipation and voltage overshoot; selection criteria emphasize capacitor voltage rating, resistor power rating, and diode recovery speed to balance efficiency and protection. RC snubbers, made up of only a resistor and capacitor, focus on damping oscillations and controlling transient voltages without a diode, often selected based on the circuit's resonant frequency, desired damping factor, and power dissipation capacity. Proper design guidelines involve calculating the optimal RC time constant and ensuring component ratings exceed maximum operating conditions to enhance reliability and suppress electromagnetic interference effectively.

Common Use Cases and Practical Examples

RCD snubbers are commonly used in switching power supplies and relay circuits to suppress voltage spikes caused by inductive loads such as motors and transformers, protecting semiconductor devices from damage. RC snubbers are frequently applied in power electronics to reduce high-frequency noise and ringing in semiconductor switches like IGBTs and MOSFETs, improving switching performance and electromagnetic interference (EMI) reduction. Practical examples include RCD snubbers in automotive relay coils and RC snubbers in inverter circuits for industrial motor drives.

Conclusion: Choosing Between RCD and RC Snubber

Choosing between an RCD snubber and an RC snubber depends on the application's voltage and power dissipation requirements; RCD snubbers excel in high-voltage environments by efficiently dissipating energy using a resistor, capacitor, and diode. RC snubbers are more suitable for lower voltage applications where simplicity and cost-effectiveness are prioritized, combining only a resistor and capacitor to suppress voltage spikes. Engineers must balance factors like switching speed, energy absorption, and circuit complexity to select the optimal snubber for reliable transient voltage protection.

Transient suppression

RCD snubbers effectively clamp voltage spikes by dissipating transient energy through a resistor-capacitor-diode network, while RC snubbers primarily reduce transient oscillations by absorbing and smoothing voltage spikes using only a resistor-capacitor circuit.

Overcurrent protection

RCD snubbers provide enhanced overcurrent protection by rapidly diverting fault currents, whereas RC snubbers primarily limit voltage spikes without effectively managing sustained overcurrent conditions.

Differential current sensing

RCD snubbers allow faster discharge of inductive energy while RC snubbers provide better differential current sensing accuracy by smoothing transient spikes.

Snubber network

An RCD snubber uses a resistor-capacitor-diode network to effectively suppress voltage spikes and protect switching devices, while an RC snubber relies on a resistor-capacitor network to reduce switching transients and dampen oscillations in power circuits.

Leakage current

RCD snubbers exhibit lower leakage current compared to RC snubbers, enhancing efficiency and reducing power losses in switching circuits.

Surge mitigation

RCD snubbers effectively dissipate high-energy voltage surges by clamping and discharging the transient, while RC snubbers reduce surge amplitude through resistive-capacitive damping, offering smoother transient suppression.

Switching transients

An RCD snubber effectively suppresses voltage spikes and ringing during switching transients by combining a resistor, capacitor, and diode to clamp the transient energy, while an RC snubber primarily reduces dv/dt and limits switching losses through a resistor-capacitor network without direct energy recovery.

Relay contact protection

RCD snubbers effectively protect relay contacts from high voltage spikes by dissipating energy through a resistor-capacitor-diode network, while RC snubbers use only resistor-capacitor components, making RCD snubbers superior in minimizing contact arcing and extending relay lifespan.

Fault current interruption

RCD snubbers provide faster fault current interruption by rapidly dissipating energy, whereas RC snubbers primarily limit voltage spikes without effectively interrupting fault currents.

Power semiconductor protection

RCD snubbers efficiently clamp voltage spikes for power semiconductor protection while RC snubbers provide energy dissipation to reduce switching losses and thermal stress.

RCD vs RC Snubber Infographic

njnir.com

njnir.com