Ethernet offers higher bandwidth and faster data transfer rates compared to traditional Fieldbus systems, making it ideal for complex industrial automation requiring real-time communication and extensive device connectivity. Fieldbus excels in deterministic control and robustness in harsh environments, providing simplified wiring and reliable performance for localized, low-speed device communication. Choosing between Ethernet and Fieldbus depends on specific application needs such as speed, network size, and environmental conditions.

Table of Comparison

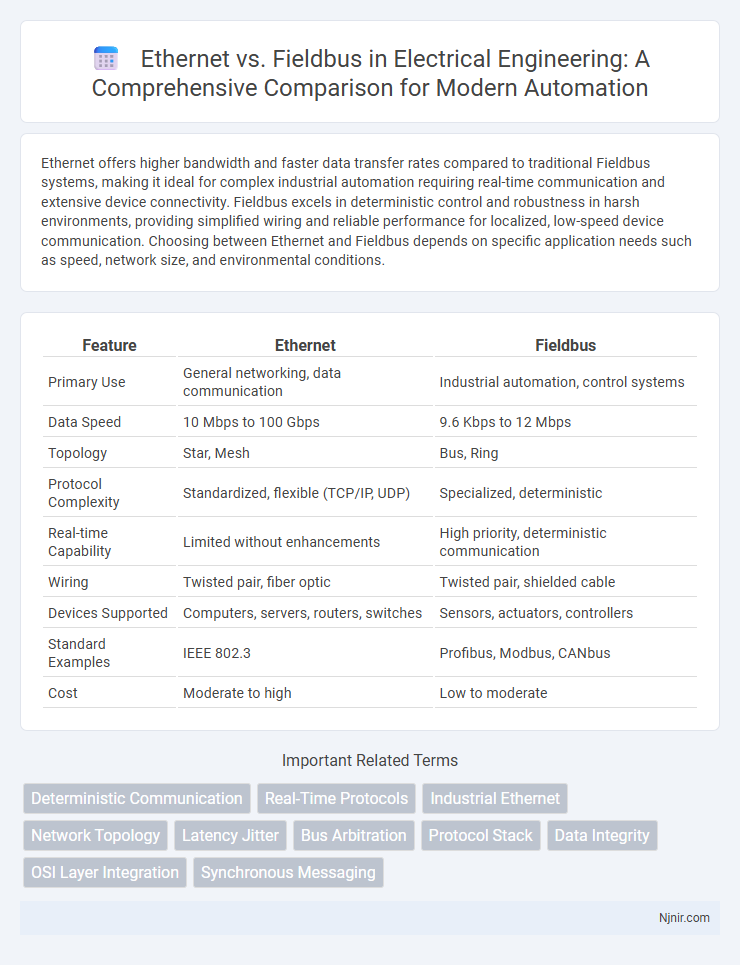

| Feature | Ethernet | Fieldbus |

|---|---|---|

| Primary Use | General networking, data communication | Industrial automation, control systems |

| Data Speed | 10 Mbps to 100 Gbps | 9.6 Kbps to 12 Mbps |

| Topology | Star, Mesh | Bus, Ring |

| Protocol Complexity | Standardized, flexible (TCP/IP, UDP) | Specialized, deterministic |

| Real-time Capability | Limited without enhancements | High priority, deterministic communication |

| Wiring | Twisted pair, fiber optic | Twisted pair, shielded cable |

| Devices Supported | Computers, servers, routers, switches | Sensors, actuators, controllers |

| Standard Examples | IEEE 802.3 | Profibus, Modbus, CANbus |

| Cost | Moderate to high | Low to moderate |

Overview of Ethernet and Fieldbus Technologies

Ethernet technology provides high-speed, scalable communication primarily used in IT networks, supporting protocols such as TCP/IP for robust data exchange. Fieldbus technology is designed for industrial automation, enabling real-time control and signaling between sensors, actuators, and controllers with standardized protocols like Profibus, Modbus, and CAN. Both technologies serve distinct roles: Ethernet excels in broad data communication, while Fieldbus offers deterministic performance essential for process control.

Key Differences Between Ethernet and Fieldbus

Ethernet supports high-speed data transfer rates up to 10 Gbps and is widely used in general network communications, while Fieldbus operates at lower speeds, typically under 1 Mbps, specifically designed for real-time industrial automation. Ethernet uses standard TCP/IP protocols for flexible network integration, whereas Fieldbus employs specialized communication protocols like PROFIBUS or Modbus, optimized for deterministic, time-critical control tasks. Ethernet networks handle extensive data traffic with broader scalability, contrasted with Fieldbus networks focused on reliable, low-latency device-to-device communication in harsh industrial environments.

Network Architecture and Topologies

Ethernet network architecture typically employs a star topology featuring switches or hubs to connect multiple devices, supporting high-speed data transfer and scalability in industrial environments. Fieldbus systems utilize a bus topology where devices are connected in series along a single communication line, optimizing deterministic communication and simplified wiring for control networks. Ethernet enables flexible, hierarchical network structures with IP-based communication, while Fieldbus provides specialized protocols tailored for real-time process control in automation systems.

Communication Protocols and Standards

Ethernet communication protocols, including IEEE 802.3 standards, offer high-speed data transfer rates up to 10 Gbps, supporting scalable and flexible industrial automation networks. Fieldbus protocols like Profibus, Foundation Fieldbus, and Modbus operate at lower speeds but provide deterministic real-time communication essential for process control and device-level integration. Ethernet's TCP/IP stack enables seamless integration with enterprise systems, whereas Fieldbus emphasizes reliability and simplicity in harsh industrial environments through specialized wiring and device interoperability standards.

Data Transmission Speed and Latency

Ethernet offers significantly higher data transmission speeds, often reaching up to 1 Gbps or more, compared to traditional Fieldbus systems that typically operate at speeds ranging from 31.25 kbps to 12 Mbps. Latency in Ethernet networks is generally lower and more consistent due to advanced switching and full-duplex capabilities, whereas Fieldbus systems may experience variable latency caused by bus arbitration and limited bandwidth. For industrial automation requiring real-time communication, Ethernet's superior speed and reduced latency provide enhanced performance over conventional Fieldbus protocols.

Reliability and Determinism in Industrial Networks

Ethernet industrial networks provide high-speed data transmission but can face challenges in achieving deterministic communication due to variable latency and potential collisions in standard configurations. Fieldbus systems, designed specifically for industrial automation, offer inherently deterministic communication with time-synchronized data exchange, ensuring predictable and reliable real-time control. Advanced Ethernet protocols like PROFINET and EtherCAT enhance reliability and determinism by implementing real-time scheduling and redundancy features, bridging the gap between traditional Ethernet flexibility and Fieldbus reliability.

Scalability and Flexibility in System Integration

Ethernet offers superior scalability and flexibility in system integration by supporting high data rates and enabling easy expansion through standardized network protocols such as TCP/IP and EtherNet/IP. Fieldbus systems provide deterministic communication suitable for smaller, fixed configurations but are limited in scalability due to proprietary protocols and slower data transfer speeds. Industrial Ethernet's compatibility with modern Internet of Things (IoT) devices and cloud-based systems further enhances its adaptability in complex, evolving automation environments.

Installation, Maintenance, and Cost Factors

Ethernet offers faster data transmission speeds and easier integration with existing IT infrastructure but requires skilled installation and higher initial costs due to complex cabling and networking equipment. Fieldbus systems feature simpler wiring and lower installation expenses, making them suitable for smaller or legacy automation setups, with maintenance often involving straightforward segment checks and replacements. Maintenance costs for Ethernet can be higher due to the need for ongoing network management and cybersecurity measures, while Fieldbus maintenance is generally less intensive but may lack scalability for complex systems.

Typical Applications in Industrial Automation

Ethernet technology is widely used in industrial automation for high-speed data communication in applications such as real-time process control, machine monitoring, and smart manufacturing systems, supporting protocols like PROFINET and EtherNet/IP. Fieldbus systems, including Profibus, Modbus, and DeviceNet, are typically implemented in distributed control systems for sensor-actuator communication, offering deterministic performance in safety-critical environments and legacy equipment integration. Both Ethernet and Fieldbus play crucial roles, with Ethernet favored for large-scale data exchange and Fieldbus optimized for robust, real-time device-level communication in industrial automation networks.

Future Trends: Ethernet Evolution vs. Fieldbus Longevity

Ethernet evolution advances with higher bandwidths, real-time communication protocols like TSN (Time-Sensitive Networking), and widespread adoption in industrial IoT, positioning it as the backbone for future smart manufacturing systems. Fieldbus systems maintain longevity in legacy industrial environments due to their robustness, deterministic performance, and established infrastructure, especially in process automation and hazardous areas. Industry trends indicate a gradual shift towards Ethernet-based solutions while supporting Fieldbus for stable, mission-critical applications during the transition phase.

Deterministic Communication

Ethernet offers high-speed data transfer but lacks inherent deterministic communication, whereas Fieldbus systems provide deterministic communication essential for real-time industrial control applications.

Real-Time Protocols

Ethernet-based real-time protocols like EtherCAT and PROFINET offer higher data transfer speeds and deterministic communication compared to traditional Fieldbus systems such as PROFIBUS and DeviceNet, enhancing industrial automation performance.

Industrial Ethernet

Industrial Ethernet offers higher data transfer speeds, improved real-time communication, and enhanced scalability compared to traditional Fieldbus systems, making it ideal for modern industrial automation networks.

Network Topology

Ethernet supports flexible star and hierarchical network topologies with high data rates, while Fieldbus typically uses linear or bus topologies optimized for real-time industrial control and deterministic communication.

Latency Jitter

Ethernet exhibits lower latency jitter compared to traditional Fieldbus systems, enabling more consistent and deterministic communication for real-time industrial control applications.

Bus Arbitration

Ethernet uses Carrier Sense Multiple Access with Collision Detection (CSMA/CD) for bus arbitration, enabling devices to detect and manage data collisions, whereas Fieldbus employs deterministic master-slave or token-passing arbitration methods to ensure prioritized and collision-free data transmission in industrial networks.

Protocol Stack

Ethernet utilizes a layered protocol stack based on the OSI model with TCP/IP for high-speed data transmission, while Fieldbus employs a simplified, application-specific protocol stack optimized for real-time industrial control and deterministic communication.

Data Integrity

Ethernet offers higher data integrity than Fieldbus by utilizing advanced error detection, correction protocols, and faster real-time communication capabilities in industrial automation networks.

OSI Layer Integration

Ethernet operates primarily at the OSI model's Physical and Data Link layers enabling high-speed, standardized communication, while Fieldbus integrates more deeply across the Data Link and Application layers to support deterministic real-time control in industrial automation systems.

Synchronous Messaging

Ethernet supports high-speed synchronous messaging with precise time synchronization protocols like IEEE 1588, whereas Fieldbus systems typically rely on deterministic but slower cyclic communication for synchronous data transfer.

Ethernet vs Fieldbus Infographic

njnir.com

njnir.com