Synchronous motors operate at a constant speed synchronized with the supply frequency, making them ideal for applications requiring precise speed control. Asynchronous motors, also known as induction motors, run at speeds slightly less than the supply frequency and are favored for their robustness and simplicity. The choice between synchronous and asynchronous motors depends on factors such as load characteristics, efficiency requirements, and control complexity.

Table of Comparison

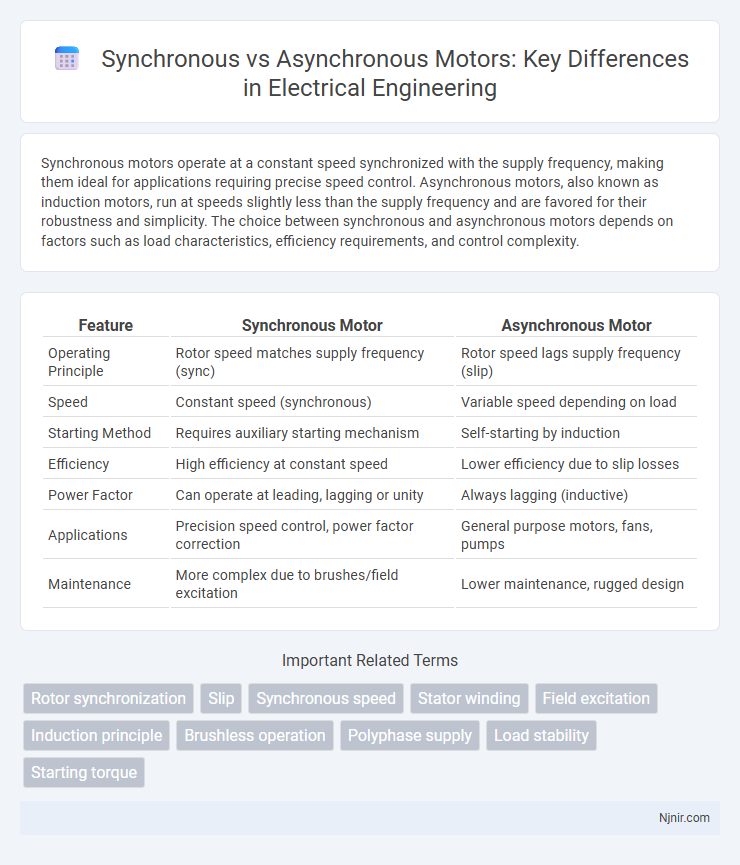

| Feature | Synchronous Motor | Asynchronous Motor |

|---|---|---|

| Operating Principle | Rotor speed matches supply frequency (sync) | Rotor speed lags supply frequency (slip) |

| Speed | Constant speed (synchronous) | Variable speed depending on load |

| Starting Method | Requires auxiliary starting mechanism | Self-starting by induction |

| Efficiency | High efficiency at constant speed | Lower efficiency due to slip losses |

| Power Factor | Can operate at leading, lagging or unity | Always lagging (inductive) |

| Applications | Precision speed control, power factor correction | General purpose motors, fans, pumps |

| Maintenance | More complex due to brushes/field excitation | Lower maintenance, rugged design |

Introduction to Synchronous and Asynchronous Motors

Synchronous motors operate at constant speed synchronized with the supply frequency, making them ideal for precise speed control applications. Asynchronous motors, also known as induction motors, run at speeds slightly less than the supply frequency, offering robust performance with simpler construction and lower maintenance costs. Both motor types are essential in industrial and commercial settings, with synchronous motors favored for high-efficiency and load-sensitive operations, while asynchronous motors provide versatility and reliability.

Fundamental Operating Principles

Synchronous motors operate based on the principle that the rotor rotates at the same speed as the stator's rotating magnetic field, achieved through the excitation of the rotor winding by a direct current. Asynchronous motors, or induction motors, rely on electromagnetic induction to produce current in the rotor winding, causing it to rotate at a speed slightly less than the stator's magnetic field, known as slip. The fundamental difference lies in synchronous motors requiring external excitation for rotor magnetization, while asynchronous motors induce rotor currents via relative motion.

Construction Differences

Synchronous motors feature rotor windings supplied with direct current, producing a constant magnetic field that rotates in sync with the stator's rotating magnetic field, while asynchronous motors have squirrel-cage rotors without external excitation, relying on induced currents to generate rotor magnetism. The construction of synchronous motors includes slip rings and brushes or permanent magnets, whereas asynchronous motors lack these components, resulting in a simpler and more rugged design. These differences impact maintenance requirements, with synchronous motors needing periodic brush inspection and asynchronous motors offering greater durability in harsh environments.

Starting Mechanisms

Synchronous motors start using an external prime mover or a separate starting mechanism like a pony motor or damper winding to bring the rotor up to synchronous speed before locking in with the stator's rotating magnetic field. Asynchronous motors, also known as induction motors, rely on electromagnetic induction generated by the stator to produce a starting torque without any external assistance. The difference in starting mechanisms impacts efficiency, control complexity, and application suitability in industrial environments.

Speed Control and Torque Characteristics

Synchronous motors maintain a constant speed determined by the supply frequency, making precise speed control challenging without varying the supply frequency through inverters. Asynchronous motors exhibit slip, allowing their speed to vary with load changes, providing inherent speed regulation and simpler control under varying torque demands. Torque in synchronous motors remains consistent at synchronous speed, while asynchronous motors produce torque through rotor slip, enabling better torque adaptability during load fluctuations.

Efficiency and Power Factor Comparison

Synchronous motors typically exhibit higher efficiency and a near-unity power factor due to their ability to operate at synchronous speed without slip, minimizing energy losses. Asynchronous (induction) motors generally have lower efficiency and a lagging power factor because of rotor slip and induced current losses. Optimizing power factor using synchronous motors can lead to energy savings and improved system stability in industrial applications.

Applications in Industry

Synchronous motors are widely used in industries requiring precise speed control and constant speed operation, such as in robotics, conveyor systems, and large compressors. Asynchronous motors, also known as induction motors, dominate applications like pumps, fans, and industrial mixers due to their robustness, low cost, and ease of maintenance. The choice between synchronous and asynchronous motors depends on factors like efficiency requirements, load characteristics, and the need for power factor correction in industrial environments.

Advantages and Limitations

Synchronous motors offer precise speed control and high efficiency, making them ideal for applications requiring constant speed under varying loads, but they require complex starting mechanisms and are generally more expensive. Asynchronous motors provide simplicity, robustness, and low cost, with self-starting capabilities, yet they exhibit slip-induced speed variations and lower overall efficiency compared to synchronous motors. The choice depends on application-specific needs such as speed stability, cost constraints, and maintenance considerations.

Selection Criteria for Motor Type

Selection criteria for synchronous versus asynchronous motors primarily depend on application requirements such as speed precision and load characteristics. Synchronous motors are preferred for applications demanding constant speed and high efficiency, such as conveyors and robotics, due to their ability to maintain sync with the supply frequency. On the other hand, asynchronous motors, also known as induction motors, are favored for their robustness, cost-effectiveness, and simplicity, making them ideal for variable loads and general industrial use.

Future Trends and Innovations in Electric Motors

Future trends in electric motors emphasize the integration of advanced materials like high-temperature superconductors to enhance synchronous motor efficiency and power density. Innovations in asynchronous motors include the development of smart control algorithms and sensorless technology to improve performance and reduce energy consumption. Both motor types are increasingly incorporating IoT connectivity and AI-driven predictive maintenance for optimized operation in industrial and automotive applications.

Rotor synchronization

The rotor in a synchronous motor rotates at the same speed as the stator's rotating magnetic field, maintaining constant synchronization, whereas the rotor in an asynchronous motor lags behind the stator field speed, resulting in slip.

Slip

Slip in asynchronous motors varies with load and speed, enabling self-starting operation, while synchronous motors operate with zero slip by maintaining constant rotor speed synchronized with the stator's magnetic field.

Synchronous speed

Synchronous motors operate at a constant synchronous speed determined by the power supply frequency and the number of poles, while asynchronous motors run below synchronous speed due to slip.

Stator winding

The stator winding in synchronous motors generates a constant rotating magnetic field synchronized with the rotor speed, whereas in asynchronous motors, it produces a rotating magnetic field that induces rotor current and operates at a slip relative to the rotor speed.

Field excitation

Synchronous motors use external field excitation through DC current to create a constant magnetic field in the rotor, while asynchronous motors rely on induced currents from the stator's rotating magnetic field for rotor excitation.

Induction principle

Synchronous motors operate based on the principle of magnetic field synchronization between the rotor and stator, whereas asynchronous motors rely on electromagnetic induction to generate rotor current and torque through slip.

Brushless operation

Brushless synchronous motors offer precise speed control and higher efficiency compared to asynchronous motors, which rely on slip and typically have lower power density in brushless designs.

Polyphase supply

Polyphase supply powers synchronous motors by creating a rotating magnetic field that locks rotor speed to supply frequency, whereas asynchronous motors operate with a rotor speed slightly less than the rotating field, producing slip for torque generation.

Load stability

Synchronous motors provide superior load stability by maintaining constant speed under varying loads, while asynchronous motors experience speed fluctuations due to slip.

Starting torque

Synchronous motors typically have low starting torque and require external means to start, while asynchronous (induction) motors provide high starting torque inherently due to rotor slip.

synchronous vs asynchronous motor Infographic

njnir.com

njnir.com