Stepper motors provide precise, incremental movement ideal for applications requiring accurate position control without feedback systems. Servo motors offer higher torque and speed with feedback mechanisms that ensure dynamic response and accurate positioning under varying loads. Choosing between stepper and servo motors depends on the need for precision, load requirements, and control complexity in the electrical engineering design.

Table of Comparison

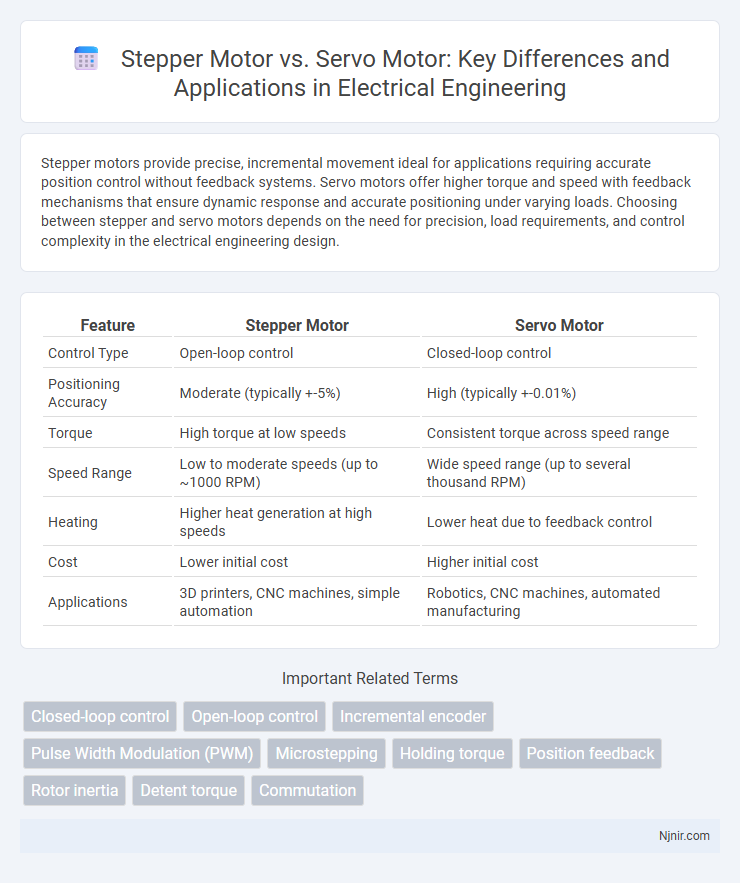

| Feature | Stepper Motor | Servo Motor |

|---|---|---|

| Control Type | Open-loop control | Closed-loop control |

| Positioning Accuracy | Moderate (typically +-5%) | High (typically +-0.01%) |

| Torque | High torque at low speeds | Consistent torque across speed range |

| Speed Range | Low to moderate speeds (up to ~1000 RPM) | Wide speed range (up to several thousand RPM) |

| Heating | Higher heat generation at high speeds | Lower heat due to feedback control |

| Cost | Lower initial cost | Higher initial cost |

| Applications | 3D printers, CNC machines, simple automation | Robotics, CNC machines, automated manufacturing |

Introduction to Stepper and Servo Motors

Stepper motors provide precise control through discrete step movements, commonly used in applications requiring accurate positioning like 3D printers and CNC machines. Servo motors deliver continuous rotation with feedback systems that ensure high torque and speed control, ideal for robotics and automation requiring dynamic performance. Both motor types play crucial roles in motion control but differ significantly in design, operational principles, and application suitability.

Fundamental Operating Principles

Stepper motors operate by dividing a full rotation into a series of discrete steps controlled by electrical pulses, allowing precise control of position without feedback systems. Servo motors rely on a continuous feedback loop using encoders or resolvers to adjust motor position and speed dynamically for high precision and torque. The fundamental difference lies in open-loop control of stepper motors versus closed-loop control in servo motors, affecting their response accuracy and application suitability.

Key Differences in Design and Functionality

Stepper motors use discrete step movements driven by digital pulses, offering precise position control without feedback systems, while servo motors rely on continuous rotation with real-time feedback via encoders for accurate position and speed control. Stepper motors typically have simpler designs with open-loop control, making them cost-effective for low to medium precision applications; servo motors feature more complex closed-loop systems that enable higher torque, speed, and dynamic response. The design difference impacts their functionality: stepper motors excel in holding torque and repeatability at low speeds, whereas servo motors offer higher efficiency, smoother motion, and adaptability in high-performance and variable load environments.

Control Methods and Signal Types

Stepper motors operate using open-loop control with pulse signals, where each pulse corresponds to a discrete step, enabling precise position control without feedback. Servo motors utilize closed-loop control systems that rely on feedback signals such as encoders or resolvers to continuously adjust motor position, speed, and torque. The control method in servo motors allows for higher precision and dynamic response compared to the stepper motor's simpler pulse-driven control.

Precision and Accuracy Comparison

Stepper motors provide precise positioning by moving in fixed angular increments, making them suitable for applications requiring repeatable, open-loop control with moderate accuracy. Servo motors offer higher accuracy and precision through closed-loop feedback systems using encoders, enabling smooth motion and correction of position errors in real time. Precision in servo motors typically exceeds that of stepper motors, with servo systems achieving resolutions as fine as 0.001 degrees compared to the common 1.8-degree step angle in stepper motors.

Torque, Speed, and Power Characteristics

Stepper motors provide precise position control with moderate torque at low to medium speeds, making them ideal for applications requiring accurate stepwise movement. Servo motors offer higher torque across a wide speed range with faster acceleration and smoother motion, driven by closed-loop feedback systems for dynamic performance. In terms of power characteristics, servo motors typically deliver greater power efficiency and thermal management, supporting demanding industrial and robotic tasks compared to stepper motors.

Applications in Electrical Engineering

Stepper motors excel in applications requiring precise position control without feedback, commonly used in 3D printers, CNC machines, and robotics for incremental motion control. Servo motors dominate in high-torque, high-speed systems demanding closed-loop feedback, such as automation equipment, robotic arms, and aerospace control surfaces. Electrical engineering projects leverage stepper motors for cost-effective, open-loop control, while servo motors are preferred where dynamic response and positional accuracy are critical.

Advantages and Limitations of Stepper Motors

Stepper motors offer precise position control and simple construction, making them ideal for applications requiring open-loop control without feedback systems. Their advantages include high reliability, low cost, and ease of use in low-speed and high-torque scenarios. Limitations involve lower efficiency, reduced torque at high speeds, and potential resonance issues compared to servo motors, which restrict their performance in dynamic and high-precision tasks.

Advantages and Limitations of Servo Motors

Servo motors offer high precision, torque, and speed control, making them ideal for applications requiring accurate positioning and smooth operation. Their closed-loop feedback system enhances performance and efficiency but increases complexity and cost compared to stepper motors. Limitations include sensitivity to electromagnetic interference and the need for sophisticated controllers, which can complicate maintenance in certain environments.

Cost, Maintenance, and Selection Criteria

Stepper motors generally offer lower initial costs and simpler maintenance due to their open-loop control systems, making them ideal for applications requiring precise positioning without feedback mechanisms. Servo motors, while more expensive upfront and demanding more complex maintenance because of their closed-loop feedback control, provide higher efficiency, torque, and accuracy for dynamic and high-performance tasks. Selection criteria depend on the application's speed, precision, torque requirements, and budget constraints, with stepper motors favored for lower-cost, low-to-medium torque tasks and servo motors chosen for high-speed, high-torque, and precision-driven environments.

Closed-loop control

Stepper motors operate with open-loop control relying on fixed step increments, whereas servo motors utilize closed-loop control systems with feedback sensors to achieve precise position, speed, and torque regulation.

Open-loop control

Stepper motors use open-loop control to achieve precise position by dividing rotations into fixed steps, while servo motors typically rely on closed-loop feedback for accurate positioning and dynamic response.

Incremental encoder

Incremental encoders in stepper motors provide basic position feedback by counting pulses per step, while servo motors use more precise incremental encoders to continuously monitor shaft position and velocity for accurate closed-loop control.

Pulse Width Modulation (PWM)

Stepper motors utilize Pulse Width Modulation (PWM) to control current in coils for precise position steps, while servo motors use PWM signals to regulate rotor position through feedback for continuous rotational control.

Microstepping

Microstepping enhances stepper motor precision by dividing each full step into smaller steps, enabling smoother motion control compared to servo motors, which rely on feedback systems for positional accuracy.

Holding torque

Stepper motors provide consistent holding torque without power consumption when stationary, while servo motors deliver higher holding torque with active power and feedback control for precision.

Position feedback

Servo motors provide precise position feedback through closed-loop control systems, whereas stepper motors rely on open-loop control without inherent position feedback.

Rotor inertia

Stepper motors typically have higher rotor inertia than servo motors, resulting in slower acceleration and reduced dynamic response.

Detent torque

Stepper motors exhibit significant detent torque due to their permanent magnet construction, providing holding torque even when unpowered, whereas servo motors generally have minimal detent torque because their design relies on feedback-controlled torque output.

Commutation

Stepper motors use open-loop commutation with discrete step control via pulse signals while servo motors employ closed-loop commutation relying on feedback sensors like encoders for precise position and velocity adjustments.

Stepper Motor vs Servo Motor Infographic

njnir.com

njnir.com