SF6 breakers provide superior insulation and arc-quenching capabilities due to sulfur hexafluoride gas, offering excellent performance in high-voltage applications and minimal maintenance requirements. Vacuum breakers utilize vacuum interrupters to extinguish arcs efficiently, resulting in compact designs and faster recovery times ideal for medium-voltage systems. The choice between SF6 and vacuum breakers depends on environmental considerations, voltage levels, and maintenance preferences.

Table of Comparison

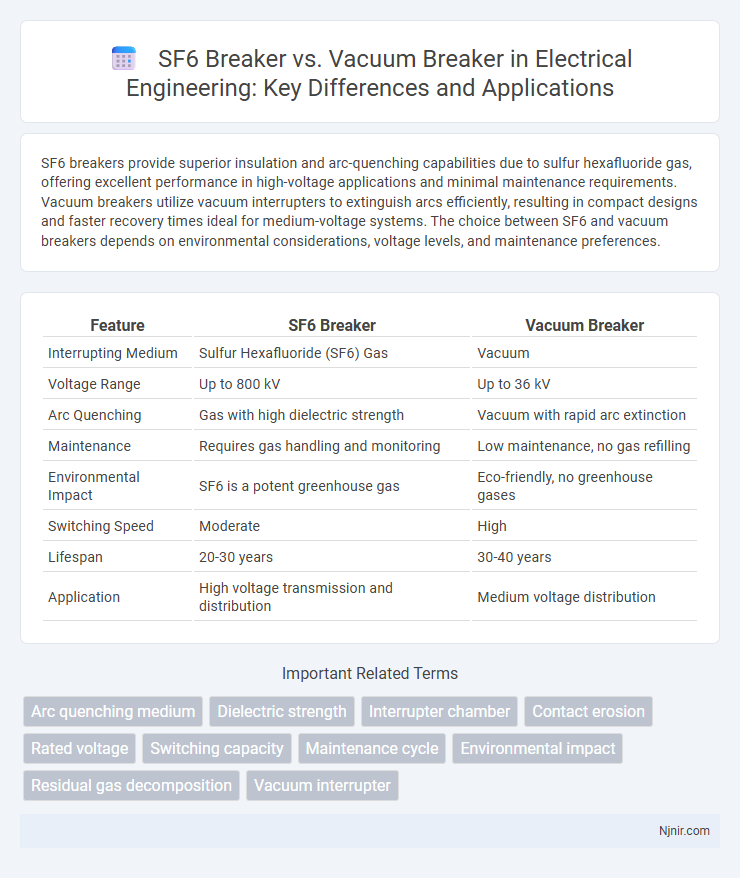

| Feature | SF6 Breaker | Vacuum Breaker |

|---|---|---|

| Interrupting Medium | Sulfur Hexafluoride (SF6) Gas | Vacuum |

| Voltage Range | Up to 800 kV | Up to 36 kV |

| Arc Quenching | Gas with high dielectric strength | Vacuum with rapid arc extinction |

| Maintenance | Requires gas handling and monitoring | Low maintenance, no gas refilling |

| Environmental Impact | SF6 is a potent greenhouse gas | Eco-friendly, no greenhouse gases |

| Switching Speed | Moderate | High |

| Lifespan | 20-30 years | 30-40 years |

| Application | High voltage transmission and distribution | Medium voltage distribution |

Introduction to SF6 and Vacuum Circuit Breakers

SF6 circuit breakers utilize sulfur hexafluoride gas as an insulating and arc-extinguishing medium, offering excellent dielectric strength and arc quenching capabilities, making them suitable for high-voltage applications up to 800 kV. Vacuum circuit breakers operate by containing the arc in a vacuum interrupter where ionized metal vapor arcs are extinguished rapidly, providing reliable performance up to medium voltage levels around 38 kV. SF6 breakers are preferred for their superior insulation and interrupting performance in extra-high voltage systems, while vacuum breakers are favored for their environmental benefits and lower maintenance in medium voltage networks.

Operating Principles of SF6 Circuit Breakers

SF6 circuit breakers operate by using sulfur hexafluoride gas to quench the arc formed when interrupting current, capitalizing on SF6's excellent dielectric and arc-extinguishing properties. The gas insulates and cools the contacts during operation, enabling effective arc suppression and rapid recovery of dielectric strength. Unlike vacuum breakers that interrupt current in a vacuum, SF6 breakers rely on the high electronegativity and thermal stability of SF6 gas for superior arc extinction in high-voltage applications.

Operating Principles of Vacuum Circuit Breakers

Vacuum circuit breakers operate by separating contacts within a vacuum, where the lack of gas molecules rapidly extinguishes the arc formed during interruption, ensuring minimal contact erosion and high dielectric strength. Unlike SF6 breakers that use sulfur hexafluoride gas for arc quenching, vacuum breakers rely on the vacuum's exceptional insulating properties to interrupt current flow, enabling reliable switching for medium voltage applications. This operating principle results in lower maintenance requirements, environmental benefits, and efficient performance in high-frequency switching scenarios.

Key Differences Between SF6 and Vacuum Breakers

SF6 breakers use sulfur hexafluoride gas as an insulating and arc-quenching medium, providing excellent dielectric strength and fast arc extinction, making them suitable for high-voltage applications. Vacuum breakers extinguish arcs by creating a vacuum environment, which results in minimal contact erosion and requires less maintenance, ideal for medium-voltage systems. Key differences include SF6 breakers' environmental concerns due to greenhouse gas emissions versus vacuum breakers' eco-friendly nature and the compact design advantage of vacuum breakers compared to the heavier SF6 types.

Dielectric Strength and Arc Quenching Methods

SF6 breakers utilize sulfur hexafluoride gas, offering superior dielectric strength of approximately 2.5 times that of air, which ensures enhanced insulation capabilities under high voltage stress. Vacuum breakers extinguish arcs by rapidly separating contacts in a vacuum environment, where the absence of gas molecules leads to an immediate arc interruption due to minimal ionization paths. The arc quenching in SF6 breakers relies on the high electronegativity of SF6 gas to capture free electrons, while vacuum breakers depend on dielectric recovery in a vacuum gap, making SF6 breakers preferable for higher voltage applications with stringent insulation requirements.

Applications in Power Systems

SF6 breakers are widely used in high-voltage power transmission systems due to their superior arc-quenching capabilities and excellent insulation properties, making them ideal for voltages above 72 kV. Vacuum breakers find extensive application in medium-voltage systems up to 38 kV, offering fast interruption speed and low maintenance requirements. Both technologies are essential for ensuring system reliability and safety in different voltage ranges within power system protection schemes.

Environmental Impact and Sustainability

SF6 breakers contain sulfur hexafluoride gas, a potent greenhouse gas with a global warming potential approximately 23,500 times that of CO2, raising significant environmental concerns during leaks or end-of-life disposal. Vacuum breakers operate without greenhouse gases, offering a more sustainable and eco-friendly solution by eliminating SF6 emissions and reducing atmospheric impact. Industry trends favor vacuum technology to meet stricter environmental regulations and promote long-term sustainability in power system protection.

Maintenance and Operational Considerations

SF6 breakers require periodic gas monitoring and handling to prevent leaks, given the gas's high global warming potential, whereas vacuum breakers demand minimal maintenance due to the sealed vacuum interrupters. Operationally, SF6 breakers provide reliable interruption in high-voltage applications with effective arc quenching but need careful environmental controls. Vacuum breakers offer faster recovery times and longer lifespans in medium-voltage networks, supported by their compact design and lower risk of insulation degradation.

Cost Comparison and Economic Analysis

SF6 breakers generally involve higher initial costs and maintenance expenses due to the specialized gas handling and environmental regulations associated with sulfur hexafluoride. Vacuum breakers, on the other hand, offer lower capital investment and reduced operational costs because they eliminate the need for gas refills and have simpler maintenance requirements. Economically, vacuum breakers provide better long-term cost efficiency and sustainability, especially in medium-voltage applications where environmental compliance and lifecycle expenses are critical factors.

Future Trends in Circuit Breaker Technology

SF6 breakers are being gradually replaced by vacuum breakers due to environmental concerns surrounding sulfur hexafluoride's high global warming potential. Future trends in circuit breaker technology emphasize eco-friendly alternatives that improve interruption performance, reduce maintenance, and support smart grid integration. Innovations include advanced vacuum interrupters with enhanced dielectric properties and digital monitoring systems enabling predictive maintenance and real-time fault detection.

Arc quenching medium

SF6 breakers use sulfur hexafluoride gas as an arc quenching medium that provides superior dielectric strength and cooling properties, while vacuum breakers extinguish arcs by creating a high vacuum environment that rapidly deionizes the arc path.

Dielectric strength

SF6 circuit breakers offer higher dielectric strength due to sulfur hexafluoride gas's superior insulating properties compared to vacuum circuit breakers' reliance on a vacuum gap.

Interrupter chamber

The interrupter chamber in SF6 breakers uses sulfur hexafluoride gas for superior arc quenching and insulation, while vacuum breakers rely on a vacuum environment to rapidly extinguish arcs by eliminating ionized particles.

Contact erosion

SF6 breakers exhibit lower contact erosion due to their superior arc-quenching gas properties compared to vacuum breakers, which rely on vacuum interrupters but experience higher erosion rates from metal vaporization.

Rated voltage

SF6 breakers typically have rated voltages up to 800 kV, while vacuum breakers are generally rated for voltages up to 38 kV, making SF6 breakers suitable for high-voltage applications and vacuum breakers ideal for medium-voltage systems.

Switching capacity

SF6 breakers offer higher switching capacity and better arc quenching performance compared to vacuum breakers, making them suitable for high-voltage and heavy-load applications.

Maintenance cycle

SF6 breakers typically require longer maintenance cycles of 5 to 10 years due to their sealed gas system, while vacuum breakers generally need more frequent maintenance every 1 to 3 years because of mechanical wear and contact erosion.

Environmental impact

SF6 breakers emit potent greenhouse gases with a global warming potential of 23,500 times that of CO2, whereas vacuum breakers have negligible environmental impact due to their non-gaseous insulation medium.

Residual gas decomposition

SF6 breakers exhibit higher residual gas decomposition due to arc byproducts compared to vacuum breakers, which generate minimal decomposition and offer cleaner interruption performance.

Vacuum interrupter

Vacuum breakers utilize vacuum interrupters that provide superior arc quenching, faster dielectric recovery, and lower environmental impact compared to SF6 breakers.

SF6 breaker vs Vacuum breaker Infographic

njnir.com

njnir.com