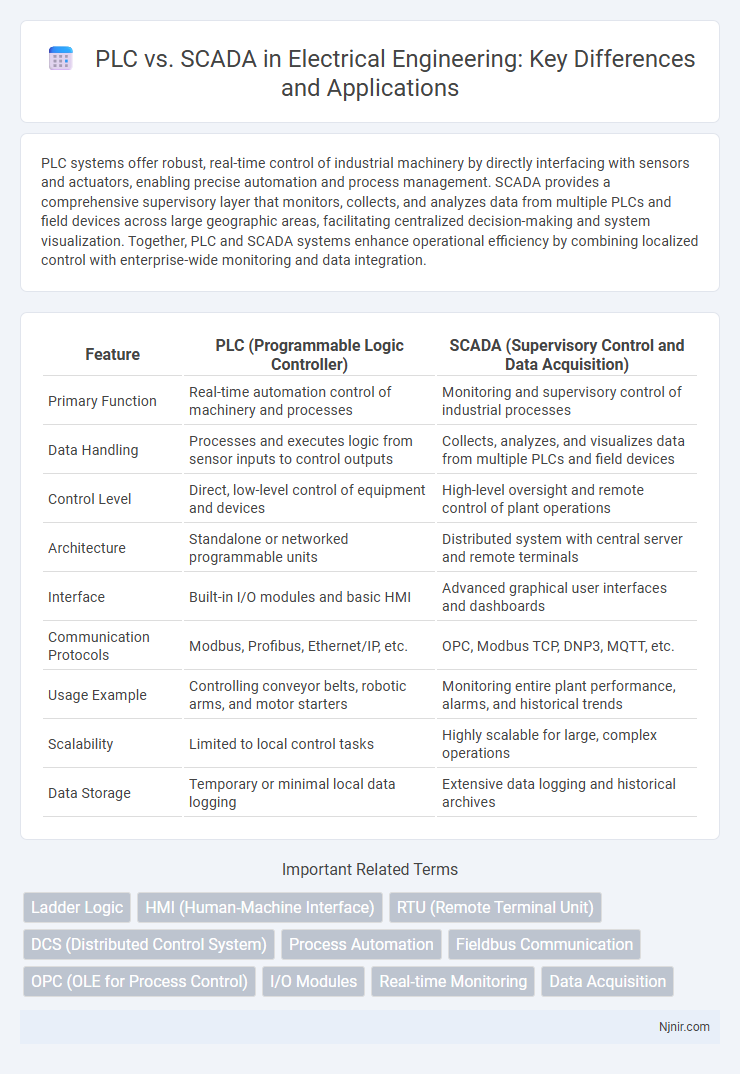

PLC systems offer robust, real-time control of industrial machinery by directly interfacing with sensors and actuators, enabling precise automation and process management. SCADA provides a comprehensive supervisory layer that monitors, collects, and analyzes data from multiple PLCs and field devices across large geographic areas, facilitating centralized decision-making and system visualization. Together, PLC and SCADA systems enhance operational efficiency by combining localized control with enterprise-wide monitoring and data integration.

Table of Comparison

| Feature | PLC (Programmable Logic Controller) | SCADA (Supervisory Control and Data Acquisition) |

|---|---|---|

| Primary Function | Real-time automation control of machinery and processes | Monitoring and supervisory control of industrial processes |

| Data Handling | Processes and executes logic from sensor inputs to control outputs | Collects, analyzes, and visualizes data from multiple PLCs and field devices |

| Control Level | Direct, low-level control of equipment and devices | High-level oversight and remote control of plant operations |

| Architecture | Standalone or networked programmable units | Distributed system with central server and remote terminals |

| Interface | Built-in I/O modules and basic HMI | Advanced graphical user interfaces and dashboards |

| Communication Protocols | Modbus, Profibus, Ethernet/IP, etc. | OPC, Modbus TCP, DNP3, MQTT, etc. |

| Usage Example | Controlling conveyor belts, robotic arms, and motor starters | Monitoring entire plant performance, alarms, and historical trends |

| Scalability | Limited to local control tasks | Highly scalable for large, complex operations |

| Data Storage | Temporary or minimal local data logging | Extensive data logging and historical archives |

Introduction to PLC and SCADA

Programmable Logic Controllers (PLCs) are industrial digital computers designed for automation of electromechanical processes, offering real-time control and reliable operation in manufacturing environments. Supervisory Control and Data Acquisition (SCADA) systems provide centralized monitoring and control of industrial processes by collecting data from sensors and remote equipment across large-scale operations. PLCs handle direct control and execution of machinery functions, while SCADA enables high-level visualization, data analysis, and operational decision-making.

Core Functions of PLC

Programmable Logic Controllers (PLCs) primarily execute real-time control tasks by monitoring inputs from sensors and devices and triggering corresponding outputs to actuators within industrial automation systems. They perform core functions such as sequential control, timing, counting, arithmetic operations, and data manipulation to maintain precise and reliable machine operations. Unlike SCADA systems that provide supervisory monitoring and data acquisition, PLCs focus on direct control and immediate decision-making at the equipment level.

Core Functions of SCADA

SCADA (Supervisory Control and Data Acquisition) systems primarily provide centralized monitoring, real-time data acquisition, and control of industrial processes, enabling operators to visualize system status and respond promptly to alarms. Core functions include data collection from PLCs and other field devices, processing and analyzing this data for decision-making, and managing automated control commands across wide geographic areas. Unlike PLCs, which execute direct control tasks at the device level, SCADA emphasizes system-wide supervision, historical data trending, and remote diagnostics to enhance operational efficiency and reliability.

Key Differences Between PLC and SCADA

PLC (Programmable Logic Controller) is a hardware device used to control machinery and automate industrial processes by executing specific logic programs. SCADA (Supervisory Control and Data Acquisition) is a software system that monitors, collects, and analyzes real-time data from multiple PLCs and other devices across large industrial operations. The key difference lies in PLC's role in direct control and automation, while SCADA provides centralized supervision, data visualization, and remote control capabilities.

Integration of PLC with SCADA Systems

The integration of PLC with SCADA systems enables seamless real-time monitoring and control of industrial processes by combining PLC's efficient data acquisition and control capabilities with SCADA's advanced visualization and supervisory functions. PLCs execute precise control algorithms at the device level, while SCADA consolidates data from multiple PLCs to provide comprehensive operational insights and remote management. This integration enhances system reliability, improves decision-making through real-time analytics, and supports scalable automation infrastructure in industries such as manufacturing, energy, and water treatment.

Advantages of PLC in Industrial Automation

PLC systems offer real-time processing capabilities crucial for precise control in industrial automation environments. They provide high reliability and robustness, functioning effectively under extreme temperatures, vibrations, and electrical noise common in manufacturing plants. PLCs support extensive input/output configurations and seamless integration with sensors and actuators, enabling efficient and scalable automation solutions.

Benefits of SCADA for Supervisory Control

SCADA systems offer enhanced real-time data visualization and centralized monitoring, improving decision-making and operational efficiency in industrial environments. Unlike PLCs, which handle direct control tasks, SCADA provides comprehensive supervisory control, enabling remote management and fault detection across multiple PLCs and field devices. This results in minimized downtime, optimized resource allocation, and improved overall system reliability.

Common Applications of PLC and SCADA

Programmable Logic Controllers (PLC) are extensively used in automated manufacturing processes, including assembly lines, robotic devices, and conveyor systems, offering real-time control and precise automation. Supervisory Control and Data Acquisition (SCADA) systems are crucial for monitoring and controlling large-scale industrial operations such as water treatment plants, power generation facilities, and oil and gas pipelines, providing centralized data acquisition and remote control capabilities. Both technologies integrate in industries like automotive, pharmaceuticals, and energy, where PLCs handle local control tasks and SCADA systems manage overall process supervision and data analysis.

Challenges and Limitations of PLC vs SCADA

PLCs face limitations in handling complex data analysis and remote monitoring compared to SCADA systems, which excel in real-time visualization and centralized control but suffer from higher implementation costs and increased cybersecurity risks. PLCs are constrained by their hardware-specific programming and limited scalability, making them less adaptable to expansive industrial networks where SCADA offers more flexibility and integration capabilities. Both systems face challenges in interoperability and require specialized expertise for maintenance, with SCADA's dependence on network stability posing additional risks in critical operations.

Future Trends in PLC and SCADA Technologies

Future trends in PLC and SCADA technologies emphasize increased integration with Industrial Internet of Things (IIoT) for enhanced data analytics and predictive maintenance. Advances in edge computing and AI-driven automation improve real-time decision-making and operational efficiency. Cybersecurity enhancements are critical as interconnected systems face growing threats, driving development in secure communication protocols and resilient architectures.

Ladder Logic

Ladder Logic is primarily used for programming PLCs to control industrial automation processes, while SCADA systems rely on PLCs and other hardware to visualize and manage the entire control system.

HMI (Human-Machine Interface)

PLCs control industrial processes through real-time automation, while SCADA systems provide comprehensive HMI dashboards for monitoring, data visualization, and remote control of multiple PLCs across large-scale operations.

RTU (Remote Terminal Unit)

RTUs in SCADA systems gather real-time data from remote PLCs to enable centralized monitoring and control of industrial processes.

DCS (Distributed Control System)

DCS integrates PLCs and SCADA systems to enhance centralized control, real-time data processing, and automation in complex industrial processes.

Process Automation

PLCs execute real-time control of industrial processes through programmable logic, while SCADA systems provide centralized monitoring and data visualization to optimize process automation efficiency.

Fieldbus Communication

Fieldbus communication enables PLCs to directly interface with field devices, while SCADA systems rely on PLCs to aggregate and transmit data for centralized monitoring and control.

OPC (OLE for Process Control)

OPC (OLE for Process Control) serves as a critical communication protocol enabling seamless data exchange between PLCs (Programmable Logic Controllers) and SCADA (Supervisory Control and Data Acquisition) systems for efficient process automation and monitoring.

I/O Modules

PLC I/O modules directly interface with sensors and actuators for real-time control, while SCADA systems primarily use I/O modules for data acquisition and remote monitoring across industrial networks.

Real-time Monitoring

PLCs provide real-time control and automation at the hardware level, while SCADA systems offer comprehensive real-time monitoring and data visualization across multiple PLCs and remote devices.

Data Acquisition

PLC efficiently controls industrial processes by directly acquiring real-time sensor data, while SCADA systems excel in centralized data acquisition, monitoring, and visualization across multiple PLCs and field devices.

PLC vs SCADA Infographic

njnir.com

njnir.com