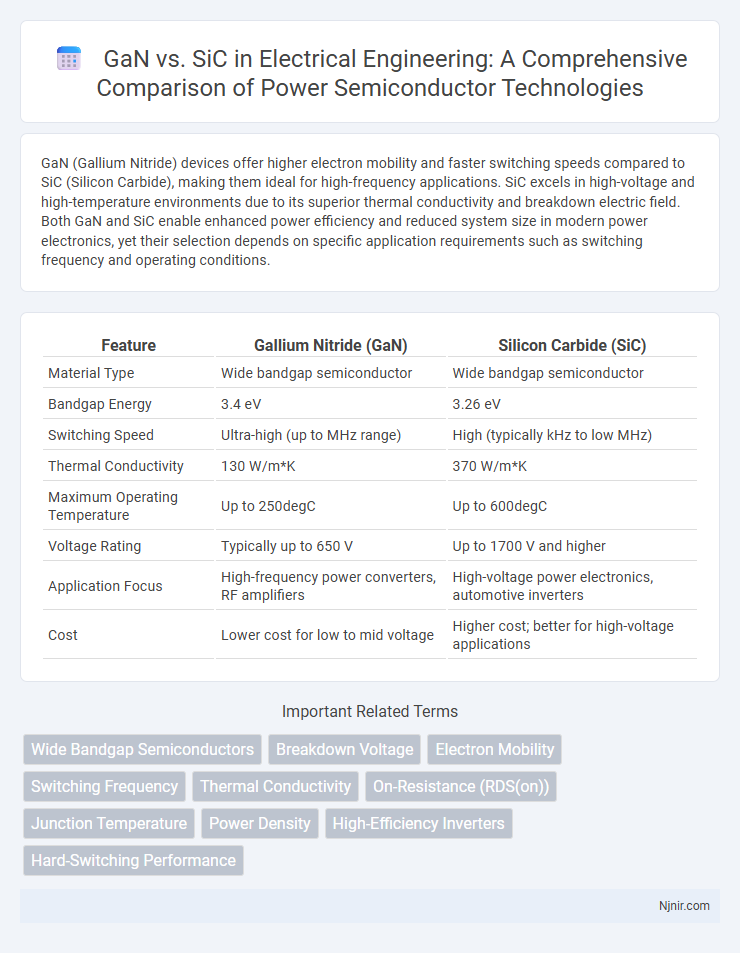

GaN (Gallium Nitride) devices offer higher electron mobility and faster switching speeds compared to SiC (Silicon Carbide), making them ideal for high-frequency applications. SiC excels in high-voltage and high-temperature environments due to its superior thermal conductivity and breakdown electric field. Both GaN and SiC enable enhanced power efficiency and reduced system size in modern power electronics, yet their selection depends on specific application requirements such as switching frequency and operating conditions.

Table of Comparison

| Feature | Gallium Nitride (GaN) | Silicon Carbide (SiC) |

|---|---|---|

| Material Type | Wide bandgap semiconductor | Wide bandgap semiconductor |

| Bandgap Energy | 3.4 eV | 3.26 eV |

| Switching Speed | Ultra-high (up to MHz range) | High (typically kHz to low MHz) |

| Thermal Conductivity | 130 W/m*K | 370 W/m*K |

| Maximum Operating Temperature | Up to 250degC | Up to 600degC |

| Voltage Rating | Typically up to 650 V | Up to 1700 V and higher |

| Application Focus | High-frequency power converters, RF amplifiers | High-voltage power electronics, automotive inverters |

| Cost | Lower cost for low to mid voltage | Higher cost; better for high-voltage applications |

Introduction to GaN and SiC Technologies

Gallium Nitride (GaN) and Silicon Carbide (SiC) are advanced semiconductor materials utilized in high-power and high-frequency applications due to their superior electron mobility and thermal conductivity compared to traditional silicon. GaN technology offers high electron velocity and efficiency, making it ideal for RF amplifiers and fast-switching power devices, while SiC excels in high-voltage, high-temperature environments, providing robustness and efficiency in power electronics such as electric vehicle inverters and industrial motor drives. Both technologies are transforming power conversion systems by enabling higher efficiency, reduced size, and improved performance across various industries.

Fundamental Material Properties: GaN vs SiC

Gallium Nitride (GaN) exhibits a wider bandgap energy of approximately 3.4 eV compared to Silicon Carbide's (SiC) 3.26 eV, enabling GaN devices to operate at higher voltages and temperatures with greater efficiency. GaN offers higher electron mobility and saturation velocity, resulting in faster switching speeds and reduced conduction losses than SiC. Although SiC has superior thermal conductivity around 4.9 W/cm*K, surpassing GaN's 1.3 W/cm*K, its robustness in high-power applications makes it ideal for heavy-duty environments.

Efficiency and Performance Comparison

Gallium Nitride (GaN) transistors exhibit higher switching speeds and lower on-resistance compared to Silicon Carbide (SiC), delivering superior efficiency in high-frequency applications such as RF amplifiers and fast chargers. SiC devices excel in high-power, high-temperature environments due to their robust thermal conductivity and voltage blocking capabilities, making them ideal for electric vehicle inverters and industrial power supplies. The choice between GaN and SiC depends on specific performance requirements: GaN offers enhanced efficiency at lower voltages and frequencies, while SiC provides better performance in high-voltage, high-power scenarios.

Thermal Management and Heat Dissipation

GaN (Gallium Nitride) exhibits superior thermal conductivity compared to traditional silicon, enabling more efficient heat dissipation in high-power electronic devices. SiC (Silicon Carbide) surpasses both GaN and Si with its even higher thermal conductivity and greater ability to withstand elevated temperatures, making it ideal for robust thermal management in power electronics. Effective heat dissipation in SiC devices reduces the need for extensive cooling systems, enhancing reliability and efficiency in applications such as electric vehicles and industrial inverters.

Switching Speed and Frequency Capabilities

GaN (Gallium Nitride) devices offer superior switching speeds compared to SiC (Silicon Carbide), with switching frequencies often exceeding several MHz, enabling higher power density and efficiency in power electronics. SiC transistors excel in high voltage and temperature environments but generally operate at lower switching frequencies, typically up to a few hundred kHz. The intrinsic material properties of GaN allow faster electron mobility, resulting in reduced switching losses and enabling applications demanding rapid switching and high-frequency operation.

Applications in Power Electronics

Gallium Nitride (GaN) power devices excel in high-frequency applications such as RF amplifiers and fast-switching power converters due to their high electron mobility and efficiency. Silicon Carbide (SiC) semiconductors are preferred for high-voltage and high-temperature environments, making them ideal for electric vehicle inverters, industrial motor drives, and renewable energy systems. Both GaN and SiC enhance power density and thermal performance, but GaN dominates low to mid-voltage ranges while SiC leads in ultra-high voltage applications above 600V.

Reliability and Durability Analysis

Gallium Nitride (GaN) devices exhibit superior reliability in high-frequency and high-temperature environments due to their wide bandgap and high electron mobility, reducing thermal degradation and enhancing lifespan compared to Silicon Carbide (SiC). SiC components demonstrate exceptional durability under extreme voltage and harsh mechanical stress, benefiting from their robust crystal lattice and high critical electric field strength. Both GaN and SiC technologies offer distinct advantages in reliability and durability, with GaN excelling in efficiency-driven applications and SiC favored for power-intensive, rugged conditions.

Manufacturing Costs and Scalability

GaN (Gallium Nitride) devices generally offer lower manufacturing costs due to simpler epitaxial growth on silicon substrates and the potential for higher wafer yields compared to SiC (Silicon Carbide), which requires more complex, time-intensive processing on expensive substrates. SiC fabrication involves high-temperature processes and less mature manufacturing infrastructure, resulting in higher per-unit costs and scalability challenges for mass production. While GaN technology scales efficiently for high-volume consumer electronics, SiC remains favored for high-power, high-temperature applications despite its cost and scalability constraints.

Recent Innovations and Industry Adoption

Recent innovations in Gallium Nitride (GaN) technology have led to higher electron mobility and efficiency in power electronics compared to Silicon Carbide (SiC), enabling faster switching speeds and reduced energy loss. SiC continues to dominate high-power, high-temperature applications due to its superior thermal conductivity and robustness, supported by extensive industry adoption in electric vehicles and renewable energy sectors. Leading semiconductor companies are accelerating GaN integration in consumer electronics and data center power supplies, driving widespread adoption through cost-effective manufacturing advancements.

Future Trends in Wide Bandgap Semiconductors

Wide bandgap semiconductors, specifically GaN and SiC, are driving significant advancements in power electronics due to their superior efficiency and thermal performance. Future trends emphasize GaN's rapid adoption in high-frequency applications like 5G infrastructure, while SiC continues to dominate high-voltage, high-power automotive and industrial sectors. Emerging research focuses on enhancing material quality, scalability, and cost reduction to accelerate widespread implementation across renewable energy, electric vehicles, and smart grid technologies.

Wide Bandgap Semiconductors

Wide bandgap semiconductors like GaN and SiC offer superior efficiency, higher breakdown voltages, and faster switching speeds compared to traditional silicon, making them ideal for high-power, high-frequency applications.

Breakdown Voltage

Gallium Nitride (GaN) devices typically exhibit lower breakdown voltage than Silicon Carbide (SiC) devices, with GaN breakdown voltages generally reaching up to 600-1200V while SiC devices can handle breakdown voltages exceeding 1700V, making SiC more suitable for high-voltage power applications.

Electron Mobility

Gallium Nitride (GaN) exhibits higher electron mobility compared to Silicon Carbide (SiC), enabling faster switching speeds and improved efficiency in power electronic devices.

Switching Frequency

Gallium Nitride (GaN) transistors achieve significantly higher switching frequencies, often exceeding several megahertz, compared to Silicon Carbide (SiC) devices due to their lower gate charge and faster electron mobility.

Thermal Conductivity

Gallium Nitride (GaN) exhibits a thermal conductivity of approximately 130 W/m*K, significantly lower than Silicon Carbide's (SiC) thermal conductivity of around 370 W/m*K, making SiC more efficient for high-power thermal management applications.

On-Resistance (RDS(on))

GaN devices typically exhibit lower On-Resistance (RDS(on)) compared to SiC devices, enabling higher efficiency and reduced conduction losses in power electronics applications.

Junction Temperature

GaN devices typically exhibit higher maximum junction temperatures around 225degC compared to SiC devices, which usually tolerate junction temperatures up to 175degC, enhancing thermal performance in high-power applications.

Power Density

GaN-based power devices achieve higher power density than SiC counterparts due to superior electron mobility and faster switching speeds.

High-Efficiency Inverters

GaN-based high-efficiency inverters outperform SiC counterparts by offering faster switching speeds, lower conduction losses, and improved thermal management, enabling enhanced power density and energy savings in advanced power electronics applications.

Hard-Switching Performance

GaN transistors demonstrate superior hard-switching performance compared to SiC devices due to lower switching losses, faster switching speeds, and reduced drain-source capacitance.

GaN vs SiC Infographic

njnir.com

njnir.com