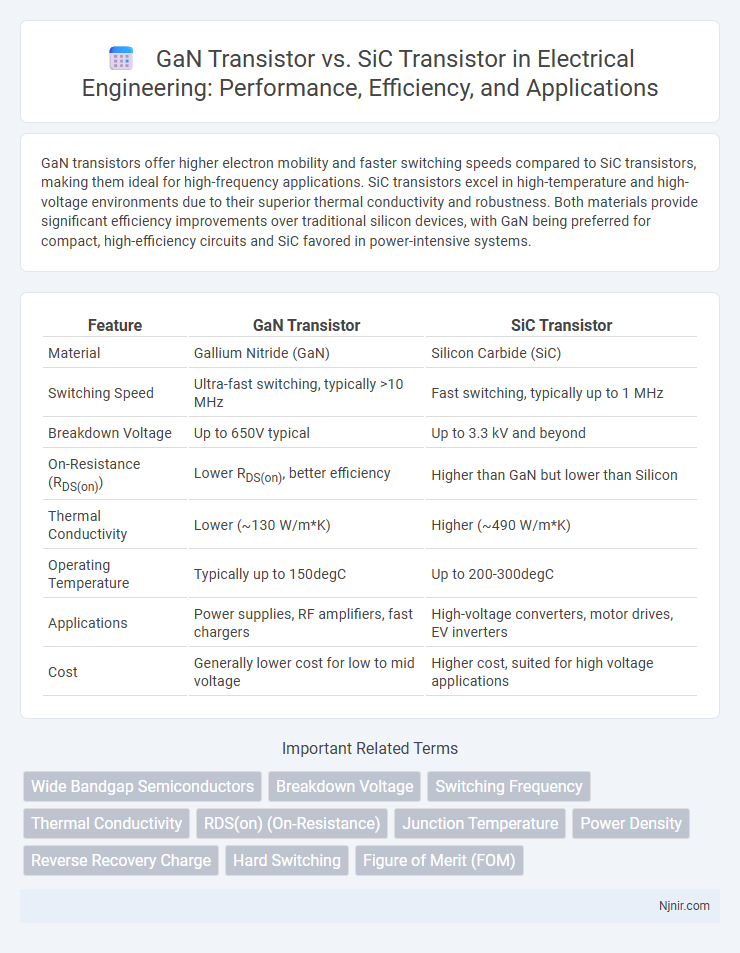

GaN transistors offer higher electron mobility and faster switching speeds compared to SiC transistors, making them ideal for high-frequency applications. SiC transistors excel in high-temperature and high-voltage environments due to their superior thermal conductivity and robustness. Both materials provide significant efficiency improvements over traditional silicon devices, with GaN being preferred for compact, high-efficiency circuits and SiC favored in power-intensive systems.

Table of Comparison

| Feature | GaN Transistor | SiC Transistor |

|---|---|---|

| Material | Gallium Nitride (GaN) | Silicon Carbide (SiC) |

| Switching Speed | Ultra-fast switching, typically >10 MHz | Fast switching, typically up to 1 MHz |

| Breakdown Voltage | Up to 650V typical | Up to 3.3 kV and beyond |

| On-Resistance (RDS(on)) | Lower RDS(on), better efficiency | Higher than GaN but lower than Silicon |

| Thermal Conductivity | Lower (~130 W/m*K) | Higher (~490 W/m*K) |

| Operating Temperature | Typically up to 150degC | Up to 200-300degC |

| Applications | Power supplies, RF amplifiers, fast chargers | High-voltage converters, motor drives, EV inverters |

| Cost | Generally lower cost for low to mid voltage | Higher cost, suited for high voltage applications |

Introduction to GaN and SiC Transistors

GaN transistors utilize gallium nitride semiconductor material, known for its wide bandgap and high electron mobility, enabling faster switching speeds and higher efficiency in power electronics. SiC transistors, made from silicon carbide, offer exceptional thermal conductivity and high breakdown voltage, making them ideal for high-power and high-temperature applications. Both GaN and SiC transistors surpass traditional silicon devices by providing improved performance in electric vehicles, renewable energy systems, and industrial power converters.

Material Properties: GaN vs. SiC

Gallium Nitride (GaN) transistors exhibit higher electron mobility and saturation velocity compared to Silicon Carbide (SiC), enabling faster switching speeds and improved high-frequency performance. SiC offers superior thermal conductivity and robustness, allowing devices to operate efficiently at higher temperatures and power densities. Material properties such as bandgap energy, with GaN around 3.4 eV and SiC approximately 3.3 eV, influence their respective breakdown voltages and leakage currents, making GaN ideal for high-frequency, low-loss applications and SiC preferable in high-power, high-temperature environments.

Switching Performance Comparison

GaN transistors exhibit faster switching speeds than SiC transistors due to their higher electron mobility and lower gate charge, resulting in reduced switching losses and improved efficiency in high-frequency applications. SiC transistors, while slower in switching speed, handle higher voltage and temperature ratings, offering robustness in harsh environments but at the cost of increased switching losses. The superior switching performance of GaN transistors makes them ideal for high-frequency power conversion, while SiC devices excel in high-voltage, high-power scenarios requiring thermal stability.

Efficiency and Power Losses

GaN transistors exhibit higher efficiency and lower power losses compared to SiC transistors due to their superior electron mobility and faster switching speeds. These characteristics enable GaN devices to operate at higher frequencies with reduced conduction and switching losses, making them ideal for applications requiring compact and energy-efficient power conversion. SiC transistors, while robust in high-voltage environments, generally have higher conduction losses and slower switching speeds relative to GaN devices.

Thermal Management and Heat Dissipation

GaN transistors exhibit superior thermal conductivity compared to SiC transistors, enabling more efficient heat dissipation in high-frequency applications. The lower thermal resistance of GaN devices reduces the need for extensive cooling systems, improving overall power density and reliability. SiC transistors, while excellent for high-temperature environments, generally require more robust thermal management due to their higher junction temperatures and larger die sizes.

Voltage and Current Handling Capabilities

GaN transistors excel in high-frequency applications due to their superior electron mobility, enabling efficient voltage handling typically up to 650V and current densities higher than traditional silicon devices. SiC transistors, on the other hand, provide robust voltage blocking capabilities often exceeding 1200V and superior current conduction, making them ideal for high-power and high-temperature environments. The choice between GaN and SiC transistors depends on the specific voltage and current requirements, with GaN favored for lower voltage, high-speed switching and SiC preferred for extreme voltage and power conditions.

Applications in Power Electronics

GaN transistors are preferred in high-frequency, high-efficiency power electronics applications such as RF amplifiers, fast chargers, and electric vehicle powertrains due to their higher electron mobility and lower on-resistance. SiC transistors excel in high-voltage, high-temperature environments like industrial motor drives, renewable energy inverters, and traction systems, offering superior thermal conductivity and robustness. Both GaN and SiC technologies are transforming power electronics by enabling smaller, lighter, and more efficient power conversion devices.

Reliability and Longevity

GaN transistors exhibit higher reliability and longer operational lifespans compared to SiC transistors due to their superior thermal conductivity and robustness against high-frequency switching stresses. Silicon Carbide transistors demonstrate excellent durability under high-voltage and high-temperature environments but may experience more significant wear in extreme switching cycles. The intrinsic material properties of GaN lead to reduced failure rates and enhanced performance stability over extended use in power electronics applications.

Cost and Availability

Gallium Nitride (GaN) transistors generally exhibit lower manufacturing costs compared to Silicon Carbide (SiC) transistors due to simpler fabrication processes and higher wafer yields. GaN transistors benefit from widespread availability in applications like RF amplifiers and fast chargers, supported by established supply chains and growing production capacity. In contrast, SiC transistors tend to be more expensive and less abundant, driven by complex production requirements and limited high-quality silicon carbide substrates.

Future Trends in Wide Bandgap Semiconductors

GaN transistors exhibit superior electron mobility and higher frequency operation, making them ideal for 5G and electric vehicle applications, while SiC transistors offer exceptional thermal conductivity and high voltage endurance, driving advancements in electric grid infrastructure and industrial motor drives. The future trend emphasizes hybrid integration of GaN and SiC technologies to maximize performance efficiency and cost-effectiveness in power electronics. Emerging research on wide bandgap materials continues to improve switching speeds, thermal management, and robustness, fueling innovation across sustainable energy and high-frequency communication systems.

Wide Bandgap Semiconductors

Wide bandgap semiconductors like GaN transistors offer higher electron mobility and faster switching speeds, while SiC transistors provide superior thermal conductivity and voltage handling for high-power applications.

Breakdown Voltage

GaN transistors typically offer lower breakdown voltage ranges up to 650V compared to SiC transistors, which provide higher breakdown voltages exceeding 1200V for high-power applications.

Switching Frequency

GaN transistors offer significantly higher switching frequencies, often exceeding several MHz, compared to SiC transistors which typically operate efficiently below 1 MHz.

Thermal Conductivity

Gallium Nitride (GaN) transistors exhibit a thermal conductivity of approximately 130 W/m*K, significantly lower than Silicon Carbide (SiC) transistors, which possess thermal conductivity around 370 W/m*K, enabling SiC devices to better dissipate heat in high-power applications.

RDS(on) (On-Resistance)

GaN transistors typically exhibit significantly lower RDS(on) values than SiC transistors, resulting in higher efficiency and reduced conduction losses in high-frequency power applications.

Junction Temperature

GaN transistors typically operate at higher junction temperatures up to 200degC compared to SiC transistors, which can withstand junction temperatures around 250degC, making SiC more suitable for high-temperature applications.

Power Density

GaN transistors deliver higher power density than SiC transistors due to superior electron mobility and breakdown voltage, enabling more efficient and compact power electronics designs.

Reverse Recovery Charge

GaN transistors exhibit significantly lower reverse recovery charge compared to SiC transistors, resulting in faster switching speeds and reduced switching losses in power electronics applications.

Hard Switching

GaN transistors offer faster switching speeds and lower switching losses compared to SiC transistors, making them more efficient for hard switching applications in high-frequency power converters.

Figure of Merit (FOM)

GaN transistors typically exhibit a higher Figure of Merit (FOM) than SiC transistors due to their superior electron mobility and lower on-resistance, leading to enhanced efficiency and faster switching speeds in power electronics applications.

GaN transistor vs SiC transistor Infographic

njnir.com

njnir.com