SC connectors offer a push-pull coupling mechanism that provides quick and secure fiber optic connections, making them ideal for high-density applications. FC connectors feature a screw-on mechanism that ensures strong, vibration-resistant connections, commonly used in high-precision environments. Both connector types differ in alignment method and durability, influencing their suitability depending on network requirements and installation conditions.

Table of Comparison

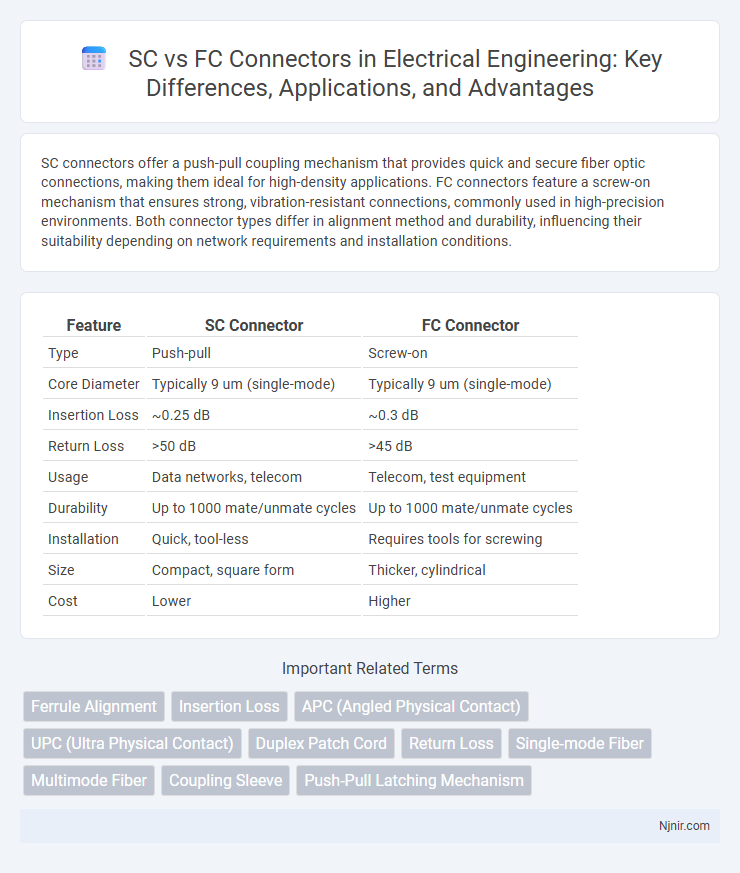

| Feature | SC Connector | FC Connector |

|---|---|---|

| Type | Push-pull | Screw-on |

| Core Diameter | Typically 9 um (single-mode) | Typically 9 um (single-mode) |

| Insertion Loss | ~0.25 dB | ~0.3 dB |

| Return Loss | >50 dB | >45 dB |

| Usage | Data networks, telecom | Telecom, test equipment |

| Durability | Up to 1000 mate/unmate cycles | Up to 1000 mate/unmate cycles |

| Installation | Quick, tool-less | Requires tools for screwing |

| Size | Compact, square form | Thicker, cylindrical |

| Cost | Lower | Higher |

Introduction to SC and FC Connectors

SC (Subscriber Connector) and FC (Ferrule Connector) connectors are widely used in fiber optic networks for high-performance data transmission. SC connectors feature a push-pull mechanism and snap-in connector body for easy installation and high-density connections, commonly used in datacom and telecom applications. FC connectors utilize a threaded connection that ensures secure, low-loss, and stable performance, making them ideal for single-mode fiber in precision environments like measurement and laboratory setups.

Historical Development of Fiber Optic Connectors

The historical development of fiber optic connectors began with the introduction of the FC (Ferrule Connector) in the 1980s, designed primarily for high-vibration telecom environments due to its threaded coupling mechanism providing secure connections. SC (Subscriber Connector) followed, emerging in the late 1980s as a push-pull connector that simplified installation and maintenance, becoming popular in data communication networks. Both connectors played pivotal roles in fiber optic networking evolution, with FC favored in single-mode applications for precision and SC dominating multi-mode networks for ease of use.

SC Connectors: Features and Specifications

SC connectors feature a push-pull coupling mechanism that ensures quick, secure connections ideal for high-density network environments. They offer low insertion loss typically around 0.2 dB and return loss exceeding 50 dB, supporting both single-mode and multimode fiber optic cables. The standardized 2.5mm ferrule diameter and ceramic alignment sleeve provide excellent precision and durability, making SC connectors a reliable choice for telecom and data communication applications.

FC Connectors: Features and Specifications

FC connectors feature a threaded metal body that ensures a secure, vibration-resistant connection commonly used in single-mode fiber applications. They provide low insertion loss, typically around 0.3 dB, and high return loss exceeding 50 dB, making them ideal for precision optical systems. Their robust design supports high-density cabling and reliable performance in telecommunications and measurement equipment.

Mechanical Design Differences

SC connectors feature a push-pull coupling mechanism with a rectangular ferrule, providing quick and easy connections suitable for high-density applications. FC connectors use a threaded coupling mechanism with a cylindrical ferrule, which ensures a secure and vibration-resistant connection ideal for precision and high-performance environments. The distinct mechanical designs impact durability, installation speed, and application suitability between SC and FC connectors.

Insertion Loss and Performance Comparison

SC connectors typically exhibit insertion loss values around 0.2 to 0.5 dB, ensuring efficient signal transmission with minimal power loss. FC connectors, known for their threaded design, often achieve lower insertion loss, approximately 0.1 to 0.3 dB, providing superior performance in high-vibration environments. Overall, FC connectors offer enhanced mechanical stability and consistently lower insertion loss compared to SC connectors, making them preferable for precision optical applications.

Applications in Electrical and Communication Systems

SC connectors are widely used in fiber optic communication systems for their push-pull design, ensuring quick and reliable connections in data centers and telecommunication networks. FC connectors are favored in high-precision electrical measurement instruments and industrial telecom applications due to their threaded coupling mechanism, providing superior durability and stability under vibration. Both connectors are essential in optimizing signal integrity and performance in various electrical and communication systems.

Durability and Reliability Factors

SC connectors feature a robust push-pull locking mechanism that enhances durability by minimizing accidental disconnections and physical wear over time. FC connectors use a screw-on design that provides a secure and stable connection, making them highly reliable in environments subject to vibration or movement. Both connector types are designed with ceramic ferrules to ensure long-term signal integrity and resistance to physical and environmental stresses.

Cost Analysis: SC vs FC Connectors

SC connectors typically offer a lower cost per unit compared to FC connectors, making them a more budget-friendly choice for large-scale deployments. FC connectors, known for their robust metal screw-type design, tend to incur higher manufacturing and material costs, impacting overall expenses. When evaluating total system cost, factors such as installation time and maintenance requirements amplify the cost advantage of SC connectors in many fiber optic applications.

Choosing the Right Connector for Your Project

Selecting the right connector for your project depends on factors like application type, space constraints, and performance requirements. SC connectors offer a push-pull coupling mechanism ideal for quick connections in high-density environments, while FC connectors feature a screw-on mechanism providing superior durability and precision, suitable for single-mode fiber applications. Understanding these distinctions ensures optimal signal integrity and system reliability tailored to your specific fiber optic network needs.

Ferrule Alignment

SC connectors feature a push-pull coupling with precise ferrule alignment using a ceramic ferrule and guide, while FC connectors use a threaded coupling and rely on a keyed ferrule for rotational alignment ensuring stable, low-loss optical connections.

Insertion Loss

SC connectors typically exhibit lower insertion loss ranging from 0.1 to 0.3 dB, while FC connectors usually have a slightly higher insertion loss around 0.2 to 0.5 dB due to their threaded design.

APC (Angled Physical Contact)

SC and FC connectors with APC (Angled Physical Contact) offer superior return loss performance due to their 8-degree angled end face, minimizing back reflections in high-precision fiber optic applications.

UPC (Ultra Physical Contact)

UPC (Ultra Physical Contact) connectors in SC and FC types provide low insertion loss and high return loss, with SC connectors offering easy push-pull connections while FC connectors ensure robust screw-threaded stability for precise fiber alignment.

Duplex Patch Cord

Duplex patch cords with SC connectors feature a push-pull locking mechanism for secure connections, while those with FC connectors utilize a screw-on design for enhanced durability in fiber optic networks.

Return Loss

SC connectors typically offer higher return loss with values around -55 dB, indicating better signal reflection performance compared to FC connectors, which usually have return loss values near -45 dB.

Single-mode Fiber

SC connectors offer push-pull coupling for single-mode fiber applications providing reliable low-loss connections, while FC connectors use threaded coupling to ensure superior stability and precision alignment in high-vibration single-mode fiber environments.

Multimode Fiber

SC connectors offer a robust push-pull design ideal for multimode fiber applications with high-density installations, while FC connectors provide superior precision and low insertion loss, making them preferred for multimode fiber systems requiring high performance and durability.

Coupling Sleeve

SC connectors use push-pull coupling sleeves for quick installation and reliable alignment, while FC connectors feature threaded coupling sleeves providing secure, vibration-resistant connections ideal for high-precision fiber optic applications.

Push-Pull Latching Mechanism

SC connectors feature a push-pull latching mechanism that enables quick, secure, and easy fiber optic cable connections, unlike FC connectors which use a screw-on mechanism for more stable but less convenient coupling.

SC vs FC Connectors Infographic

njnir.com

njnir.com