AC grounding involves connecting electrical systems to the earth to safely dissipate alternating current fault currents, ensuring system stability and operator safety. DC grounding typically manages direct current circuits, preventing potential differences that could cause equipment damage or hazardous conditions by maintaining a constant reference potential. Proper design of both AC and DC grounding systems minimizes electrical noise, interference, and enhances overall protection against electrical faults.

Table of Comparison

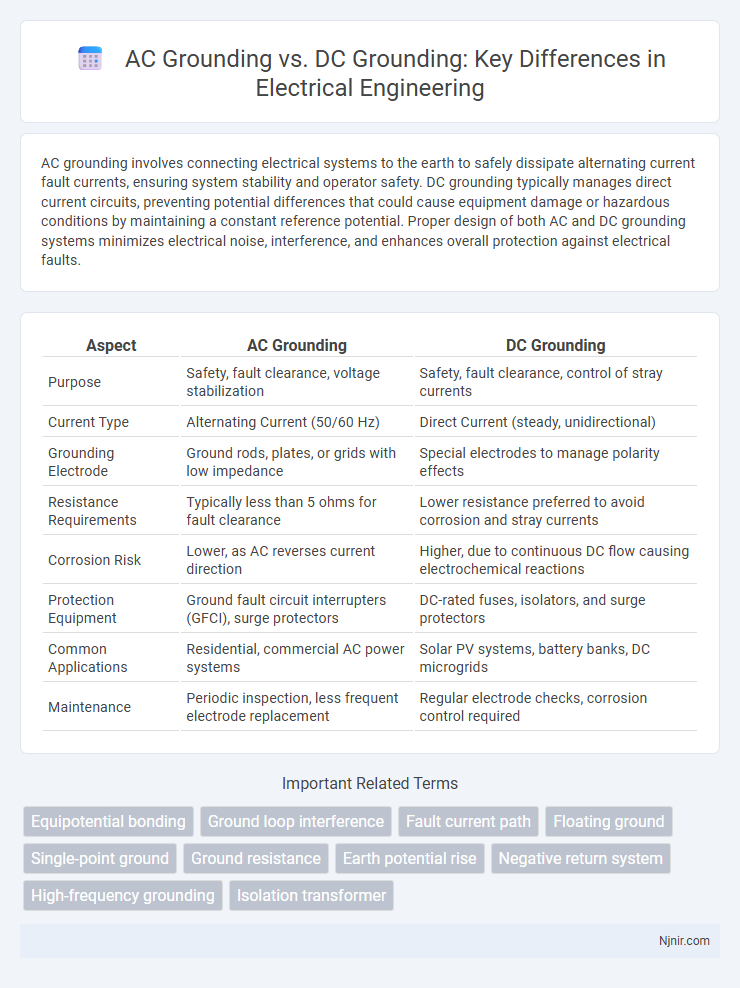

| Aspect | AC Grounding | DC Grounding |

|---|---|---|

| Purpose | Safety, fault clearance, voltage stabilization | Safety, fault clearance, control of stray currents |

| Current Type | Alternating Current (50/60 Hz) | Direct Current (steady, unidirectional) |

| Grounding Electrode | Ground rods, plates, or grids with low impedance | Special electrodes to manage polarity effects |

| Resistance Requirements | Typically less than 5 ohms for fault clearance | Lower resistance preferred to avoid corrosion and stray currents |

| Corrosion Risk | Lower, as AC reverses current direction | Higher, due to continuous DC flow causing electrochemical reactions |

| Protection Equipment | Ground fault circuit interrupters (GFCI), surge protectors | DC-rated fuses, isolators, and surge protectors |

| Common Applications | Residential, commercial AC power systems | Solar PV systems, battery banks, DC microgrids |

| Maintenance | Periodic inspection, less frequent electrode replacement | Regular electrode checks, corrosion control required |

Introduction to AC and DC Grounding

AC grounding involves connecting electrical systems to the earth to stabilize voltage levels and protect against faults in alternating current circuits, ensuring safety and equipment reliability. DC grounding serves a similar purpose in direct current systems but requires distinct techniques due to the constant polarity and different fault characteristics of DC circuits. Proper grounding methods for both AC and DC systems are essential for minimizing shock hazards, reducing electromagnetic interference, and maintaining system integrity.

Fundamental Differences Between AC and DC Systems

AC grounding involves connecting alternating current systems to earth to stabilize voltage and provide a safe path for fault currents, typically using neutral grounding with resistors or reactors to limit fault current magnitude. DC grounding connects direct current systems to earth to prevent potential buildup and corrosion, often implementing grounding through low impedance paths without reactive components due to the unidirectional current flow. The fundamental difference lies in the nature of current flow: AC grounding must handle changing polarity and frequency effects, while DC grounding deals with steady-state currents and electrochemical impacts, influencing grounding design and protective measures accordingly.

Purpose and Importance of Grounding

Grounding in AC systems ensures safety by preventing electric shock and stabilizing voltage during faults, facilitating the proper operation of protective devices. In DC systems, grounding is crucial for circuit stability, preventing stray currents that can cause equipment corrosion or malfunction. Both AC and DC grounding maintain system reliability and protect personnel by providing a controlled path for fault currents, minimizing electrical hazards.

Grounding Methods for AC Systems

AC grounding methods primarily involve using a solid or resistance grounding approach to stabilize the system voltage during faults and limit fault current. Common techniques include the use of grounding transformers such as zig-zag or wye-delta, which provide a neutral point for grounding and help control transient overvoltages. Effective AC grounding ensures system protection, minimizes equipment damage, and enhances personnel safety by providing a low-resistance path to earth.

Grounding Methods for DC Systems

DC grounding methods primarily include solid grounding, resistance grounding, and ungrounded systems. Solid grounding connects the DC system directly to the earth, providing a low-resistance path for fault currents and enhancing safety by enabling rapid detection of faults. Resistance grounding uses a resistor between the DC system and ground to limit fault current magnitude, reducing equipment damage and preventing arcing in sensitive electronics common in telecom and solar power applications.

Safety Implications of AC vs DC Grounding

AC grounding systems use a low-impedance path to facilitate fault current flow, quickly triggering protective devices and minimizing shock hazards. DC grounding requires careful management to prevent issues such as electrochemical corrosion and persistent fault currents that do not pass zero crossing, increasing the risk of equipment damage and personal injury. Effective grounding designs for both AC and DC systems enhance overall electrical safety by ensuring reliable fault detection and isolation.

Common Applications and Use Cases

AC grounding is commonly applied in residential and commercial electrical systems to ensure safety by preventing electric shock and equipment damage through effective fault current dissipation. DC grounding finds frequent use in telecommunications, photovoltaic systems, and electric vehicles where stable reference points and prevention of voltage fluctuations are critical. Understanding the specific application environment helps in choosing between AC grounding techniques, which focus on alternating currents, and DC grounding methods tailored for direct current systems.

Challenges in AC and DC Grounding Implementations

AC grounding faces challenges such as frequency-dependent impedance variations and potential resonance issues that can cause unstable fault currents and voltage fluctuations. DC grounding struggles with continuous unidirectional current flow, requiring specialized methods to prevent corrosion, mitigating stray current interference, and managing potential differences over long distances. Both grounding types demand careful system design to ensure safety, minimize equipment damage, and maintain operational reliability.

Industry Standards and Regulations

Industry standards for AC grounding are primarily defined by the National Electrical Code (NEC) and IEC 60364, emphasizing safety and fault current paths to prevent electric shock and equipment damage. DC grounding standards, such as those outlined in IEEE 518 and IEC 62485, focus on minimizing corrosion, controlling voltage offset, and ensuring stable reference points in battery and photovoltaic systems. Compliance with these regulations ensures effective grounding practices tailored to the specific characteristics of AC and DC systems in industrial applications.

Future Trends in Electrical Grounding Systems

Future trends in electrical grounding systems emphasize enhanced safety and efficiency in both AC and DC grounding configurations, driven by the increasing integration of renewable energy sources and smart grids. Innovations in adaptive grounding technologies enable real-time monitoring and fault detection, improving system reliability and reducing downtime. Advanced materials and grounding techniques tailored for DC microgrids and hybrid systems are expected to optimize grounding performance and mitigate issues such as stray currents and electromagnetic interference.

Equipotential bonding

Equipotential bonding in AC grounding minimizes voltage differences and electrical shock risk, while DC grounding requires specialized bonding techniques to manage potential imbalances and corrosion risks.

Ground loop interference

Ground loop interference is more prevalent and problematic in AC grounding due to the alternating current inducing circulating currents, whereas DC grounding generally experiences less interference because of its steady current flow.

Fault current path

AC grounding provides a low-impedance fault current path through the earth neutral conductor enabling rapid fault clearance, whereas DC grounding requires careful design to ensure a continuous fault current return path often through dedicated grounding electrodes or isolated systems.

Floating ground

Floating ground in AC systems reduces noise and interference by isolating the return path, whereas DC floating grounds primarily prevent ground loops and corrosion in sensitive electronic circuits.

Single-point ground

Single-point grounding in AC systems minimizes noise and interference by connecting all grounds to a single reference point, whereas in DC systems it primarily prevents ground loops and ensures stable voltage reference.

Ground resistance

AC grounding requires lower ground resistance to effectively dissipate fault currents due to alternating current's frequency-dependent skin effect, while DC grounding demands stable and continuous low resistance to prevent voltage buildup and maintain system safety.

Earth potential rise

AC grounding systems require careful management of Earth potential rise to prevent hazardous voltage gradients, whereas DC grounding often experiences lower Earth potential rise due to steady current flow and different fault characteristics.

Negative return system

DC negative return grounding provides a stable, low-resistance path for fault currents, enhancing system safety and reliability compared to AC grounding, which typically involves earth references and fluctuating impedance.

High-frequency grounding

High-frequency grounding in AC systems requires low-impedance paths to minimize noise and interference, whereas DC grounding emphasizes stable, continuous reference points to prevent voltage drift and corrosion.

Isolation transformer

Isolation transformers provide enhanced safety in AC grounding by preventing direct electrical connection to the main supply, whereas DC grounding often requires different techniques due to the absence of alternating polarity and the risk of continuous current paths.

AC grounding vs DC grounding Infographic

njnir.com

njnir.com