Copper clad materials offer superior electrical conductivity and excellent heat dissipation, making them ideal for high-frequency and high-power applications. FR4, a glass-reinforced epoxy laminate, provides mechanical strength, flame resistance, and cost-effectiveness, commonly used in standard printed circuit boards. Selecting copper clad over FR4 enhances signal integrity and thermal management but typically increases manufacturing complexity and cost.

Table of Comparison

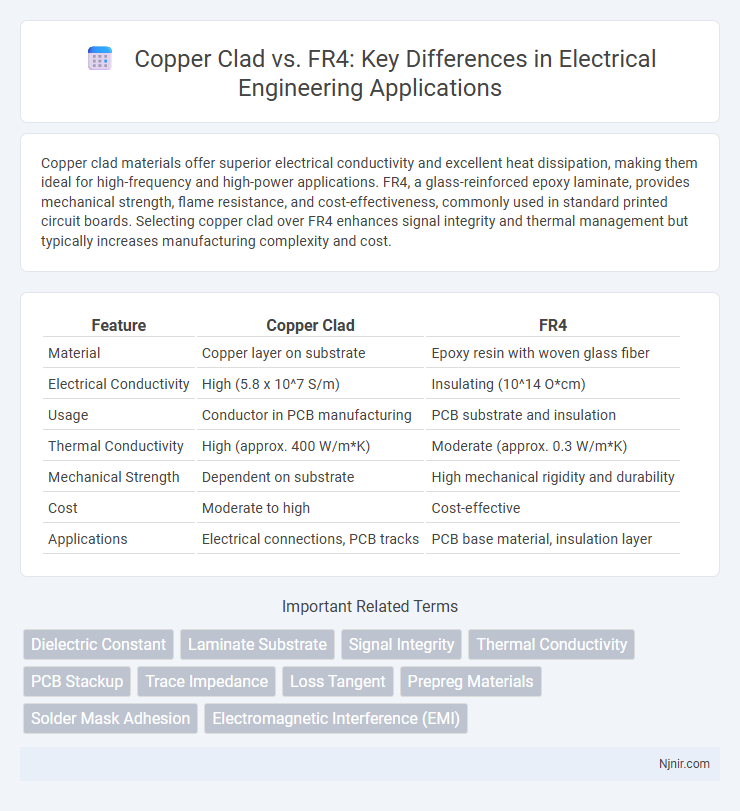

| Feature | Copper Clad | FR4 |

|---|---|---|

| Material | Copper layer on substrate | Epoxy resin with woven glass fiber |

| Electrical Conductivity | High (5.8 x 10^7 S/m) | Insulating (10^14 O*cm) |

| Usage | Conductor in PCB manufacturing | PCB substrate and insulation |

| Thermal Conductivity | High (approx. 400 W/m*K) | Moderate (approx. 0.3 W/m*K) |

| Mechanical Strength | Dependent on substrate | High mechanical rigidity and durability |

| Cost | Moderate to high | Cost-effective |

| Applications | Electrical connections, PCB tracks | PCB base material, insulation layer |

Introduction to Copper Clad and FR4 Materials

Copper clad refers to a composite material consisting of a thin layer of copper bonded to a non-conductive substrate, commonly used in printed circuit boards (PCBs) for excellent electrical conductivity and durability. FR4 is a widely utilized material for PCB substrates, composed of woven fiberglass cloth combined with an epoxy resin binder, offering high mechanical strength, flame resistance, and electrical insulation. Understanding the properties of copper clad and FR4 is essential for designing reliable electronic circuits and ensuring optimal performance in various industrial applications.

Composition and Manufacturing Processes

Copper clad laminates consist of a thin layer of copper foil bonded to a substrate, commonly made of fiberglass-reinforced epoxy resin, whereas FR4 is a specific grade of fiberglass epoxy laminate known for its flame-retardant properties. The manufacturing process of copper clad involves laminating the copper foil onto the substrate through heat and pressure, ensuring strong adhesion and electrical conductivity. FR4 production includes the precise layering of woven fiberglass cloth impregnated with epoxy resin, followed by curing and heat pressing, resulting in a durable, moisture-resistant PCB base material.

Electrical Properties Comparison

Copper clad laminates exhibit superior electrical conductivity with a typical conductivity of about 5.8 x 10^7 S/m, vastly outperforming FR4, which is primarily an insulating material with a dielectric constant (Dk) around 4.5 and a low dissipation factor (Df) near 0.02 at 1 MHz. The low loss tangent of FR4 makes it suitable for high-frequency circuit applications, while copper clad materials enhance current carrying capacity and reduce signal attenuation due to lower resistance. Together, these electrical properties determine performance trade-offs in circuit board design, influencing signal integrity, thermal management, and overall reliability.

Thermal Performance Analysis

Copper clad materials exhibit superior thermal conductivity compared to FR4, enabling more efficient heat dissipation in high-power electronic applications. FR4, a composite epoxy laminate, has a lower thermal conductivity typically around 0.3-0.4 W/mK, while copper clad substrates can reach thermal conductivities above 200 W/mK. This significant difference enhances thermal management, reducing the risk of overheating and improving the reliability and longevity of electronic components.

Mechanical Strength and Durability

Copper Clad laminates offer enhanced mechanical strength due to their metal layer, providing superior rigidity and resistance to mechanical stress compared to FR4, which is a fiberglass epoxy laminate known for its balance of strength and flexibility. FR4 excels in durability under varying thermal cycles and moisture exposure, maintaining its structural integrity and electrical insulation properties in harsh environments. The choice between Copper Clad and FR4 hinges on application demands, with Copper Clad favored for robust, high-stress mechanical environments, while FR4 is preferred for general-purpose, cost-effective, and thermally stable printed circuit board substrates.

Applications in PCB Design

Copper clad laminates provide excellent electrical conductivity and thermal management, making them ideal for high-frequency and power electronics applications in PCB design. FR4, a fiberglass-reinforced epoxy laminate, is widely used due to its strong mechanical properties, flame resistance, and cost-effectiveness, suitable for consumer electronics and general-purpose circuit boards. Choosing between copper clad and FR4 depends on required electrical performance, thermal stability, and application-specific durability demands.

Cost Considerations and Availability

Copper Clad materials generally offer a lower cost solution compared to FR4 due to simpler manufacturing processes and widespread availability from multiple suppliers. FR4, a fiberglass-reinforced epoxy laminate, tends to be more expensive but provides enhanced mechanical strength and thermal stability, making it suitable for high-performance applications. Availability of copper clad sheets is typically higher in standard sizes, whereas FR4 availability varies depending on thickness and quality grades required, impacting lead times and overall procurement costs.

Environmental and Safety Factors

Copper Clad materials often pose higher environmental risks due to copper's potential toxicity and challenges in recycling compared to FR4, which contains epoxy resin and fiberglass that are more stable and less hazardous but harder to biodegrade. FR4's flame retardant properties reduce fire hazards, enhancing safety during manufacturing and usage, whereas uncoated copper can increase fire risk if oxidized or exposed to high temperatures. Evaluating lifecycle impacts, FR4 generally offers safer handling and disposal profiles, while copper clad's environmental footprint depends significantly on copper recovery and recycling practices.

Selection Criteria for Engineers

Engineers select Copper Clad materials for high thermal conductivity and superior electrical performance in power electronics applications, while FR4 is preferred for its cost-effectiveness and mechanical stability in standard PCB designs. The decision hinges on factors such as thermal management requirements, dielectric constant, and environmental operating conditions. Evaluating parameters like thermal conductivity (Copper Clad up to 400 W/mK versus FR4 typically around 0.3 W/mK) and dielectric loss ensures optimal performance and reliability in specific engineering applications.

Future Trends in PCB Substrate Materials

Copper clad and FR4 remain foundational materials in PCB manufacturing, but future trends signal a shift towards advanced substrates like high-frequency laminates and flexible materials to meet escalating performance demands. Emerging technologies prioritize thermal management, signal integrity, and miniaturization, driving innovation beyond traditional copper clad FR4 composites. Integration of eco-friendly and high-reliability materials also characterizes the trajectory of next-generation PCB substrates for 5G, IoT, and wearable electronics.

Dielectric Constant

Copper clad materials typically exhibit a stable dielectric constant around 4.5, while FR4's dielectric constant ranges from 4.2 to 4.8, influencing signal integrity and impedance in PCB design.

Laminate Substrate

Copper clad laminate substrate offers superior electrical conductivity and enhanced thermal dissipation compared to FR4, making it ideal for high-performance printed circuit boards.

Signal Integrity

Copper Clad materials provide superior signal integrity compared to FR4 due to lower dielectric losses and better conductivity, reducing signal attenuation and crosstalk in high-frequency PCB applications.

Thermal Conductivity

Copper Clad laminates offer significantly higher thermal conductivity, typically around 400 W/mK, compared to FR4 material which has thermal conductivity near 0.3 W/mK, making copper clad ideal for efficient heat dissipation in electronic circuits.

PCB Stackup

Copper Clad PCB stackups offer enhanced conductivity and thermal management compared to FR4, which primarily serves as an insulating substrate with lower thermal conductivity and electrical performance.

Trace Impedance

Copper Clad substrates offer more consistent trace impedance control compared to FR4 due to their uniform copper thickness and superior dielectric properties.

Loss Tangent

Copper Clad materials generally exhibit lower loss tangent values compared to FR4, making them more suitable for high-frequency PCB applications requiring minimal signal attenuation.

Prepreg Materials

Copper clad prepreg materials offer enhanced electrical performance and durability compared to standard FR4 prepregs due to their superior dielectric properties and moisture resistance.

Solder Mask Adhesion

Copper clad substrates exhibit superior solder mask adhesion compared to FR4 due to their enhanced surface roughness and chemical compatibility.

Electromagnetic Interference (EMI)

Copper Clad substrates provide superior electromagnetic interference (EMI) shielding compared to FR4, reducing signal degradation in high-frequency electronic applications.

Copper Clad vs FR4 Infographic

njnir.com

njnir.com