Busbars provide a compact and efficient method for distributing large amounts of electrical power within switchboards and panel boards, offering lower resistance and reduced voltage drop compared to cables. Unlike cables, busbars have a lower thermal rise and are easier to maintain due to their rigid, accessible structure. They are ideal for high-current applications and complex power distribution layouts where space optimization and heat dissipation are critical.

Table of Comparison

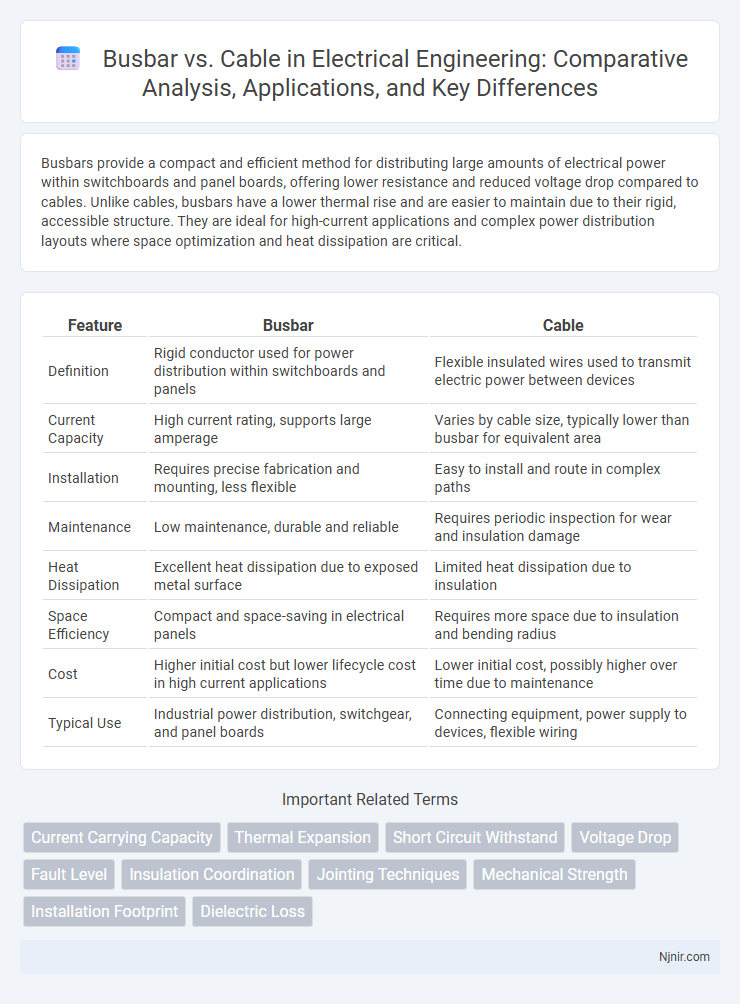

| Feature | Busbar | Cable |

|---|---|---|

| Definition | Rigid conductor used for power distribution within switchboards and panels | Flexible insulated wires used to transmit electric power between devices |

| Current Capacity | High current rating, supports large amperage | Varies by cable size, typically lower than busbar for equivalent area |

| Installation | Requires precise fabrication and mounting, less flexible | Easy to install and route in complex paths |

| Maintenance | Low maintenance, durable and reliable | Requires periodic inspection for wear and insulation damage |

| Heat Dissipation | Excellent heat dissipation due to exposed metal surface | Limited heat dissipation due to insulation |

| Space Efficiency | Compact and space-saving in electrical panels | Requires more space due to insulation and bending radius |

| Cost | Higher initial cost but lower lifecycle cost in high current applications | Lower initial cost, possibly higher over time due to maintenance |

| Typical Use | Industrial power distribution, switchgear, and panel boards | Connecting equipment, power supply to devices, flexible wiring |

Introduction to Busbar and Cable Systems

Busbars and cables are essential components in electrical distribution systems, designed to efficiently conduct large currents within power networks. Busbars, typically made of copper or aluminum, provide a rigid, compact, and low-resistance path for electricity, enabling effective load management and simplified connections in switchgear, panel boards, and substations. Cables, insulated and flexible, are used for power transmission over distances, offering versatility in routing and ease of installation for both low and high-voltage applications.

Fundamental Differences Between Busbars and Cables

Busbars provide a rigid, low-resistance path for large current flow and are typically used in switchgear, panel boards, and busway enclosures, offering high mechanical strength and efficient heat dissipation. Cables consist of insulated conductors designed for flexible installation in various routing scenarios, providing electrical connectivity over longer distances with protection against environmental factors. The fundamental differences lie in busbars' rigid structure optimized for high current carrying capacity in confined spaces, whereas cables prioritize flexibility, insulation, and ease of installation across diverse environments.

Material Composition and Types

Busbars are typically made from highly conductive metals such as copper or aluminum, designed to carry large electrical currents with minimal resistance and heat generation. Cables consist of multiple insulated copper or aluminum wires, allowing for flexible routing and varying voltage levels in electrical distribution. Both busbars and cables vary in types, with busbars including solid, laminated, and insulated varieties, while cables are categorized into power, control, and communication cables based on their specific applications.

Electrical Performance and Efficiency

Busbars provide superior electrical performance due to their low resistance and higher current carrying capacity compared to cables, reducing energy losses and improving overall system efficiency. Their rigid, solid structure ensures stable conductor spacing, minimizing electromagnetic interference and voltage drop, which enhances operational reliability. Unlike cables, busbars also facilitate better heat dissipation, preventing overheating and maintaining consistent electrical conductivity under heavy load conditions.

Installation and Space Requirements

Busbars require less installation time due to their modular design and simplified connection points compared to cables, which involve multiple terminations and extended routing. Space-wise, busbars occupy significantly less room, offering a compact solution especially beneficial in confined electrical panels or switchgear environments. Cable installations often demand additional space for bends and cable management systems, increasing overall footprint and complexity.

Safety Considerations and Risk Factors

Busbars offer enhanced safety due to their robust construction and reduced exposure to loose connections, lowering the risk of electrical arcing and overheating compared to cables. Cables, when poorly installed or degraded, can pose increased risks of insulation failure, short circuits, and fire hazards. Proper maintenance, insulation quality, and installation practices are critical to minimizing safety risks in both busbars and cables.

Maintenance and Longevity

Busbars require less maintenance compared to cables due to their rigid, enclosed design that minimizes exposure to environmental factors and wear. Their robust construction ensures longer operational life, with reduced risk of insulation degradation and mechanical damage. In contrast, cables often demand frequent inspections and replacements, especially in high-stress or corrosive environments, impacting overall longevity and maintenance costs.

Cost Analysis and Economic Impact

Busbars generally offer lower installation and maintenance costs compared to cables due to their modular structure and ease of assembly in electrical distribution systems. Cables often incur higher expenses related to labor-intensive installation, increased material usage for insulation, and greater susceptibility to damage necessitating frequent replacements. The economic impact favors busbars in large-scale industrial applications where long-term efficiency and reduced downtime translate into significant cost savings over the system's lifecycle.

Applications in Electrical Engineering

Busbars provide efficient power distribution in high-current electrical systems due to their low impedance and heat dissipation capabilities, making them ideal for switchgear, panel boards, and industrial power distribution. Cables are preferred in flexible wiring applications and long-distance power transmission where routing through complex pathways is necessary, commonly used in building wiring, machines, and overhead power lines. The choice between busbars and cables depends on current capacity, installation environment, and maintenance requirements in electrical engineering projects.

Choosing Between Busbar and Cable: Key Factors

Choosing between busbars and cables depends on current capacity, installation space, and heat dissipation requirements. Busbars offer higher current carrying capacity and better heat dissipation in compact spaces, making them ideal for high-power applications and electrical panels. Cables provide flexibility and ease of installation in complex routing scenarios but may require more space and exhibit higher heat buildup at equivalent current ratings.

Current Carrying Capacity

Busbars offer higher current carrying capacity than cables due to their larger cross-sectional area and better heat dissipation properties.

Thermal Expansion

Busbars exhibit lower thermal expansion compared to cables, enhancing stability and reducing mechanical stress in electrical systems.

Short Circuit Withstand

Busbars exhibit higher short circuit withstand capacity compared to cables due to their superior thermal stability and lower impedance.

Voltage Drop

Busbars exhibit significantly lower voltage drop compared to cables due to their larger cross-sectional area and superior conductivity, making them more efficient for high-current, low-voltage-drop electrical distribution.

Fault Level

Busbars typically offer higher fault current ratings and superior heat dissipation compared to cables, making them more suitable for applications with elevated fault level requirements.

Insulation Coordination

Busbar systems offer superior insulation coordination compared to cables by providing consistent dielectric strength and minimized partial discharge risks in high-voltage switchgear applications.

Jointing Techniques

Busbar jointing techniques prioritize low-resistance welding and bolted connections for high current efficiency, while cable jointing focuses on insulated heat-shrink sleeves and crimp terminals to ensure secure, flexible electrical continuity.

Mechanical Strength

Busbars provide superior mechanical strength compared to cables due to their rigid, solid metal construction designed to withstand higher physical stress and vibration.

Installation Footprint

Busbars offer a significantly smaller installation footprint compared to cables, reducing space requirements and simplifying electrical panel design.

Dielectric Loss

Busbars exhibit lower dielectric loss compared to cables due to their solid conductive structure and minimal insulation layers, resulting in enhanced energy efficiency in electrical distribution systems.

Busbar vs Cable Infographic

njnir.com

njnir.com