Active rectifiers utilize semiconductor switches controlled by external signals to achieve higher efficiency, reduced harmonic distortion, and better power factor correction compared to passive rectifiers. Passive rectifiers rely on diodes and passive components, resulting in simpler design but higher losses and less control over the output waveform. Active rectification enables dynamic adjustment to varying load conditions, making it ideal for advanced power electronics applications demanding precise voltage regulation and minimal electromagnetic interference.

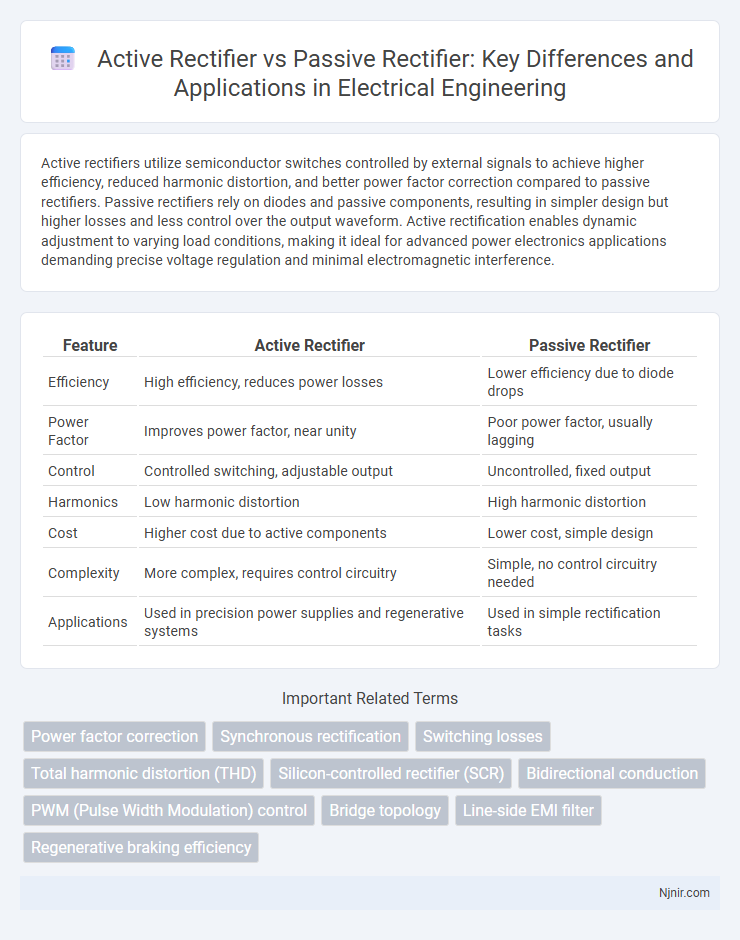

Table of Comparison

| Feature | Active Rectifier | Passive Rectifier |

|---|---|---|

| Efficiency | High efficiency, reduces power losses | Lower efficiency due to diode drops |

| Power Factor | Improves power factor, near unity | Poor power factor, usually lagging |

| Control | Controlled switching, adjustable output | Uncontrolled, fixed output |

| Harmonics | Low harmonic distortion | High harmonic distortion |

| Cost | Higher cost due to active components | Lower cost, simple design |

| Complexity | More complex, requires control circuitry | Simple, no control circuitry needed |

| Applications | Used in precision power supplies and regenerative systems | Used in simple rectification tasks |

Introduction to Rectification in Electrical Engineering

Active rectifiers use semiconductor devices like MOSFETs controlled by external signals to convert AC to DC with higher efficiency and reduced harmonic distortion, enabling bidirectional power flow and improved power factor correction. Passive rectifiers rely on diodes that conduct when forward-biased, providing a simple, robust, and cost-effective solution but with fixed conversion voltage and higher losses due to diode drops. In electrical engineering, rectification transforms alternating current (AC) into direct current (DC), essential for powering DC loads and enabling applications in power supplies, motor drives, and renewable energy systems.

Overview of Active and Passive Rectifiers

Active rectifiers utilize semiconductor devices like MOSFETs or IGBTs controlled by external signals to precisely regulate the conversion of AC to DC power, enhancing efficiency and minimizing harmonic distortion. Passive rectifiers rely on diodes and lack control elements, making them simpler and more robust but less efficient with higher power losses and increased harmonic content. The choice between active and passive rectifiers depends on application requirements such as efficiency, power quality, and cost.

Working Principle of Passive Rectifiers

Passive rectifiers operate by using diodes to convert alternating current (AC) to direct current (DC) without external power sources, relying solely on the inherent properties of semiconductor junctions. The working principle involves allowing current to flow in a single direction during the positive half-cycle of AC while blocking reverse current during the negative half-cycle, resulting in pulsating DC output. This simple design contrasts with active rectifiers, which use controlled electronic switches for improved efficiency and reduced harmonic distortion.

Operation of Active Rectifiers

Active rectifiers utilize semiconductor switches controlled by external signals to convert AC to DC with high efficiency and minimal harmonic distortion. The operation involves real-time adjustment of switching elements to align voltage and current waveforms, ensuring near-unity power factor and reduced energy losses. Unlike passive rectifiers, which rely on diodes and fixed components, active rectifiers dynamically regulate output voltage and current, enabling improved performance in power electronics applications.

Efficiency Comparison: Active vs Passive Rectifiers

Active rectifiers use controlled semiconductor switches to reduce power losses and improve efficiency, often achieving efficiencies above 95%, whereas passive rectifiers rely on diodes that cause higher voltage drops and increased energy dissipation, resulting in lower overall efficiency. The dynamic control in active rectifiers minimizes harmonic distortion and reactive power, enhancing power factor and reducing conduction losses compared to passive designs. This efficiency advantage makes active rectifiers preferable in applications demanding energy savings and high-performance power conversion.

Harmonic Distortion and Power Quality

Active rectifiers significantly reduce harmonic distortion by employing controlled semiconductor switches and sophisticated modulation techniques, resulting in improved power quality compared to passive rectifiers. Passive rectifiers rely on diode bridges and passive filters, which often lead to higher Total Harmonic Distortion (THD) levels and inferior power factor correction, negatively impacting overall system efficiency. Implementing active rectifiers enhances power factor, minimizes voltage waveform distortion, and ensures compliance with stringent power quality standards such as IEEE 519.

Control and Flexibility in Rectifier Design

Active rectifiers offer superior control and flexibility in rectifier design by utilizing semiconductor switches and feedback control circuits to regulate output voltage and current precisely. In contrast, passive rectifiers rely on diodes and passive components, providing limited control over the output and fixed conduction angles, which restricts their adaptability to varying loads and input conditions. The advanced control schemes in active rectifiers enable dynamic response to load changes, improved power factor correction, and reduced harmonic distortion, making them ideal for modern applications requiring high efficiency and reliability.

Applications of Active Rectifiers

Active rectifiers are essential in renewable energy systems, such as solar photovoltaic inverters, due to their higher efficiency and precise control over power quality. They are widely used in electric vehicle chargers and uninterruptible power supplies (UPS) to improve energy conversion and reduce harmonic distortion. Industrial motor drives benefit from active rectifiers by achieving bidirectional power flow and enhanced power factor correction, optimizing overall system performance.

Applications of Passive Rectifiers

Passive rectifiers are widely utilized in applications requiring simple, reliable conversion of AC to DC power without the need for complex control circuitry, such as in power supplies for small electronics, battery chargers, and basic DC motor drives. Their robust design, consisting primarily of diodes, makes them suitable for environments with minimal electromagnetic interference and low-cost industrial systems. Passive rectifiers excel in scenarios where efficiency and power quality demands are moderate, and maintenance simplicity is a priority.

Future Trends in Rectifier Technology

Active rectifiers leverage advanced semiconductor devices and digital control systems to enhance energy efficiency, reduce harmonic distortion, and enable bidirectional power flow, positioning them as a key technology for future smart grids and renewable energy integration. Passive rectifiers, while simpler and cost-effective, face limitations in efficiency and power quality, which restrict their applicability in evolving high-performance power systems. Emerging trends emphasize the development of wide-bandgap semiconductors such as SiC and GaN in active rectifiers to achieve higher switching frequencies, greater thermal management, and improved overall system reliability.

Power factor correction

Active rectifiers achieve superior power factor correction by dynamically controlling input current waveform, whereas passive rectifiers rely on fixed components resulting in lower power factor efficiency and higher harmonic distortion.

Synchronous rectification

Synchronous rectification in active rectifiers utilizes MOSFETs to achieve higher efficiency and lower power loss compared to passive rectifiers that rely on diodes for current flow control.

Switching losses

Active rectifiers minimize switching losses by using controlled semiconductor switches, while passive rectifiers exhibit higher switching losses due to fixed diode conduction.

Total harmonic distortion (THD)

Active rectifiers significantly reduce Total Harmonic Distortion (THD) compared to passive rectifiers by dynamically controlling input current waveform and minimizing harmonics injection into the power system.

Silicon-controlled rectifier (SCR)

Active rectifiers using Silicon-controlled rectifiers (SCRs) provide improved control and efficiency over passive rectifiers by enabling regulated power flow and reduced harmonic distortion in AC to DC conversion.

Bidirectional conduction

Active rectifiers enable bidirectional conduction through controlled switching devices, whereas passive rectifiers rely on diodes allowing unidirectional current flow only.

PWM (Pulse Width Modulation) control

Active rectifiers using PWM control achieve higher efficiency and better power factor correction compared to passive rectifiers by actively regulating voltage and current waveforms.

Bridge topology

Active rectifiers in bridge topology improve efficiency and reduce harmonic distortion by using controlled switches, whereas passive rectifiers rely on fixed diodes, resulting in higher energy losses and lower power quality.

Line-side EMI filter

Active rectifiers generate lower line-side EMI due to their controlled switching techniques, whereas passive rectifiers rely on bulky line-side EMI filters to mitigate higher electromagnetic interference.

Regenerative braking efficiency

Active rectifiers significantly enhance regenerative braking efficiency by dynamically converting and controlling energy flow, whereas passive rectifiers offer limited energy recovery due to fixed diode-based designs.

Active rectifier vs Passive rectifier Infographic

njnir.com

njnir.com