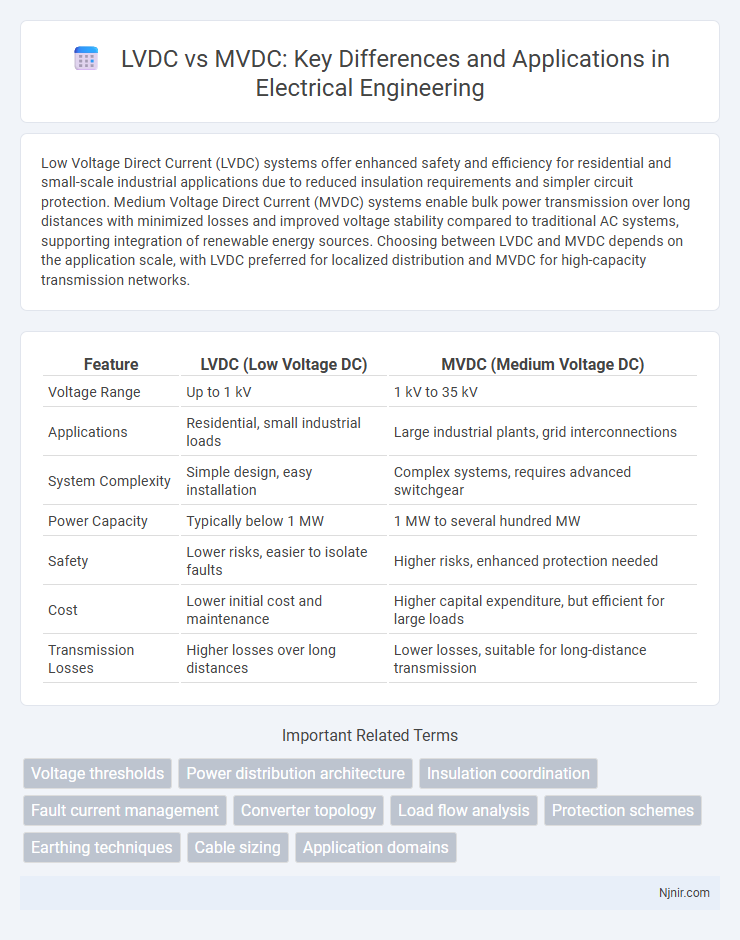

Low Voltage Direct Current (LVDC) systems offer enhanced safety and efficiency for residential and small-scale industrial applications due to reduced insulation requirements and simpler circuit protection. Medium Voltage Direct Current (MVDC) systems enable bulk power transmission over long distances with minimized losses and improved voltage stability compared to traditional AC systems, supporting integration of renewable energy sources. Choosing between LVDC and MVDC depends on the application scale, with LVDC preferred for localized distribution and MVDC for high-capacity transmission networks.

Table of Comparison

| Feature | LVDC (Low Voltage DC) | MVDC (Medium Voltage DC) |

|---|---|---|

| Voltage Range | Up to 1 kV | 1 kV to 35 kV |

| Applications | Residential, small industrial loads | Large industrial plants, grid interconnections |

| System Complexity | Simple design, easy installation | Complex systems, requires advanced switchgear |

| Power Capacity | Typically below 1 MW | 1 MW to several hundred MW |

| Safety | Lower risks, easier to isolate faults | Higher risks, enhanced protection needed |

| Cost | Lower initial cost and maintenance | Higher capital expenditure, but efficient for large loads |

| Transmission Losses | Higher losses over long distances | Lower losses, suitable for long-distance transmission |

Overview of LVDC and MVDC Systems

LVDC (Low Voltage Direct Current) systems operate typically below 1,000 volts and are ideal for residential and commercial applications requiring efficient power delivery at lower voltages. MVDC (Medium Voltage Direct Current) systems function between 1 kV and 35 kV, offering enhanced power transmission capabilities for industrial facilities and utility grids. Both LVDC and MVDC provide improved energy efficiency, reduced losses, and better control compared to traditional AC systems, with MVDC enabling long-distance power transfer and grid integration.

Key Differences Between LVDC and MVDC

LVDC (Low Voltage Direct Current) systems typically operate below 1000 volts, while MVDC (Medium Voltage Direct Current) systems function within the range of 1 kV to 35 kV, enabling MVDC to handle higher power transmission efficiently. LVDC is commonly used in residential and small commercial applications due to its safety and ease of integration, whereas MVDC is preferred in industrial and large-scale power distribution scenarios for reduced losses and improved system stability. The choice between LVDC and MVDC depends on factors like distance, power capacity, and infrastructure requirements, with MVDC offering benefits in long-distance transmission and bulk power transfer.

Voltage Ranges and Standards

LVDC (Low Voltage Direct Current) systems typically operate at voltage levels below 1,000 volts, commonly standardized between 380V and 1kV, suitable for residential and small commercial applications according to standards such as IEC 62852. MVDC (Medium Voltage Direct Current) systems operate in the range of 1kV to 35kV, aligning with standards like IEC 60781 and IEEE 1676, designed for industrial power distribution and large-scale renewable energy integration. The differentiation in voltage ranges directly influences insulation requirements, safety protocols, and equipment specifications, making adherence to respective standards critical for system reliability and interoperability.

Applications of LVDC in Electrical Engineering

LVDC (Low Voltage Direct Current) systems are increasingly utilized in residential and commercial electrical engineering applications due to their efficiency in powering LED lighting, small appliances, and electronic devices. LVDC is preferred for microgrids, renewable energy integration, and battery storage systems because it reduces energy losses and enhances safety at voltages typically below 60 volts. LVDC networks support electric vehicle charging stations, telecommunications, and data centers where precise voltage control and energy management are critical.

Applications of MVDC in Electrical Engineering

Medium Voltage Direct Current (MVDC) systems are increasingly applied in electrical engineering for efficient power transmission in microgrids, renewable energy integration, and electric ship power distribution. MVDC enables reduced energy losses and improved control over power quality compared to Low Voltage Direct Current (LVDC) systems, making it ideal for industrial plants and offshore platforms. Key applications include connecting wind farms to grids, powering DC traction systems, and enhancing reliability in hybrid AC/DC networks.

Efficiency and Power Loss Comparisons

LVDC (Low Voltage Direct Current) systems demonstrate higher efficiency in short-distance power distribution due to reduced insulation requirements and lower converter losses, primarily suitable for residential and commercial applications below 1 kV. MVDC (Medium Voltage Direct Current) systems, operating typically between 1 kV and 35 kV, excel in long-distance and high-power transmission by minimizing I2R losses through higher voltage levels and enabling thinner conductor materials, thus offering superior overall efficiency for industrial and utility-scale networks. Comparative studies reveal MVDC systems reduce power losses by up to 30% compared to LVDC in medium to large-scale implementations, promoting better scalability and energy savings in smart grid integration.

Safety Considerations: LVDC vs MVDC

Low Voltage Direct Current (LVDC) systems typically operate below 1000 volts, offering enhanced safety due to reduced electrical shock risk and simpler insulation requirements compared to Medium Voltage Direct Current (MVDC) systems, which range from 1000 to 35,000 volts and demand more robust protective gear and specialized equipment. MVDC systems present increased hazards such as arc flash risks and require stringent safety protocols including advanced fault detection and isolation mechanisms to prevent severe injuries or equipment damage. Proper training, comprehensive personal protective equipment (PPE), and adherence to industry standards like IEC 61850 are crucial in mitigating safety risks associated with both LVDC and MVDC installations.

Infrastructure and Installation Requirements

LVDC (Low Voltage Direct Current) systems require less complex infrastructure with smaller, lighter cabling and simpler protective devices, facilitating easier installation and reduced space utilization in distribution networks. MVDC (Medium Voltage Direct Current) installations demand more robust insulation, specialized switchgear, and advanced control equipment to handle higher voltages safely, leading to increased infrastructure costs and more rigorous installation procedures. Choosing between LVDC and MVDC depends on application scale, voltage levels, and the balance between installation complexity and operational efficiency.

Cost Analysis: LVDC versus MVDC

LVDC (Low Voltage Direct Current) systems typically incur lower initial infrastructure costs due to simpler insulation and switchgear requirements compared to MVDC (Medium Voltage Direct Current) systems. However, MVDC offers enhanced efficiency and reduced line losses over longer distances, potentially lowering operational expenses and total cost of ownership in large-scale applications. Cost analysis must balance upfront capital expenditure against long-term savings, factoring in project scale, distance, and load requirements for optimal economic performance.

Future Trends in DC Power Distribution

Future trends in DC power distribution emphasize the shift from Medium Voltage Direct Current (MVDC) to Low Voltage Direct Current (LVDC) systems for enhanced efficiency and scalability in renewable energy integration and electric vehicle infrastructure. LVDC systems offer improved safety, lower installation costs, and better compatibility with low-voltage smart grid technologies, fostering decentralized power generation and storage. Advancements in power electronics and semiconductor technology drive higher performance and reliability in LVDC applications, positioning it as a critical component of next-generation energy networks.

Voltage thresholds

LVDC systems typically operate below 1 kV, whereas MVDC systems function within voltage ranges from 1 kV to 35 kV, defining the primary threshold for classification.

Power distribution architecture

LVDC power distribution architecture offers enhanced energy efficiency and reduced power losses for localized applications, whereas MVDC systems enable long-distance transmission with higher voltage levels and improved grid stability.

Insulation coordination

Insulation coordination in LVDC systems requires lower dielectric strength materials due to reduced voltage stress, while MVDC systems demand advanced insulation design and higher dielectric strength to manage increased voltage levels and prevent electrical breakdown.

Fault current management

LVDC systems offer easier fault current management due to lower voltage levels and simpler protection schemes, while MVDC systems require advanced protection technologies to handle higher fault currents and ensure system stability.

Converter topology

LVDC converter topology typically employs simpler, low-voltage semiconductor devices with reduced insulation requirements, while MVDC converter topology integrates advanced modular multilevel converters (MMCs) or high-voltage direct current (HVDC) designs to efficiently handle higher voltage levels and improve power quality.

Load flow analysis

Load flow analysis in MVDC systems offers improved accuracy and stability compared to LVDC due to higher voltage levels reducing current magnitude and associated losses.

Protection schemes

LVDC protection schemes primarily utilize fuses and low-voltage circuit breakers designed for rapid fault isolation, whereas MVDC systems require advanced protection methods such as directional relays, DC circuit breakers with high interrupting capacity, and sophisticated fault detection algorithms to manage higher voltage levels and complex fault scenarios.

Earthing techniques

LVDC systems typically use solid or low-resistance grounding for earthing, while MVDC systems often implement high-resistance or resonant grounding techniques to manage fault currents and ensure system stability.

Cable sizing

LVDC cable sizing requires larger conductor cross-sections due to higher current levels compared to MVDC, which benefits from smaller cables because of higher voltage and lower current for the same power transmission.

Application domains

LVDC systems are primarily used in residential and small commercial applications for efficient low-voltage power distribution, while MVDC systems are favored in industrial, marine, and renewable energy sectors for high-voltage direct current transmission and large-scale power integration.

LVDC vs MVDC Infographic

njnir.com

njnir.com