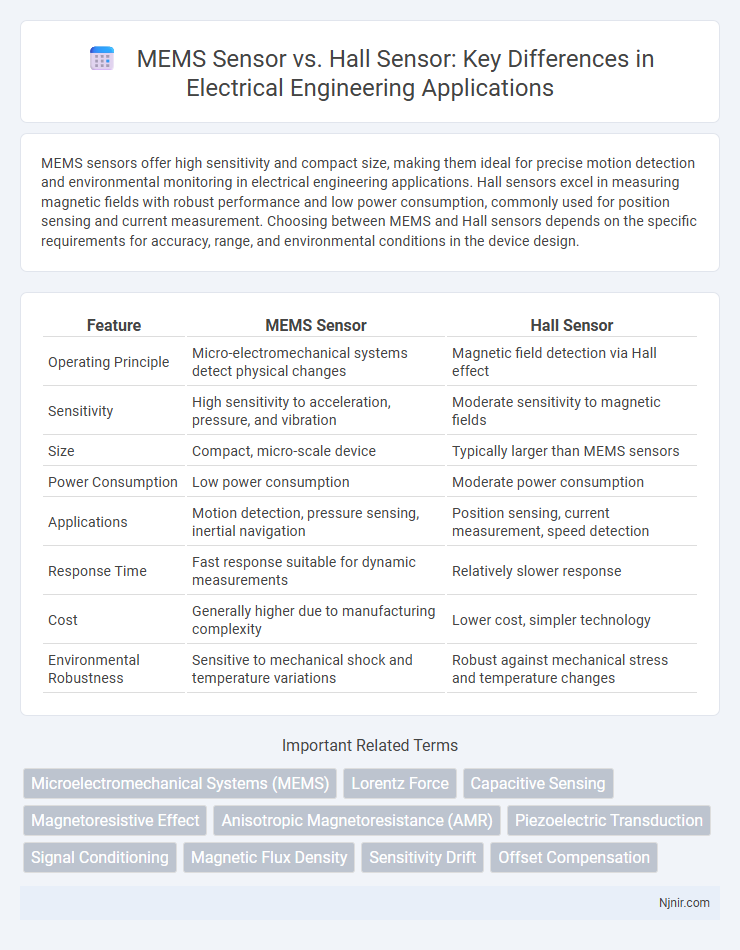

MEMS sensors offer high sensitivity and compact size, making them ideal for precise motion detection and environmental monitoring in electrical engineering applications. Hall sensors excel in measuring magnetic fields with robust performance and low power consumption, commonly used for position sensing and current measurement. Choosing between MEMS and Hall sensors depends on the specific requirements for accuracy, range, and environmental conditions in the device design.

Table of Comparison

| Feature | MEMS Sensor | Hall Sensor |

|---|---|---|

| Operating Principle | Micro-electromechanical systems detect physical changes | Magnetic field detection via Hall effect |

| Sensitivity | High sensitivity to acceleration, pressure, and vibration | Moderate sensitivity to magnetic fields |

| Size | Compact, micro-scale device | Typically larger than MEMS sensors |

| Power Consumption | Low power consumption | Moderate power consumption |

| Applications | Motion detection, pressure sensing, inertial navigation | Position sensing, current measurement, speed detection |

| Response Time | Fast response suitable for dynamic measurements | Relatively slower response |

| Cost | Generally higher due to manufacturing complexity | Lower cost, simpler technology |

| Environmental Robustness | Sensitive to mechanical shock and temperature variations | Robust against mechanical stress and temperature changes |

Overview of MEMS Sensors and Hall Sensors

MEMS sensors utilize microelectromechanical systems technology to measure physical parameters such as acceleration, pressure, and angular velocity with high sensitivity and miniaturization. Hall sensors detect magnetic fields by measuring the voltage generated across a conductor when exposed to a magnetic flux, widely used for position sensing and current measurement. Both sensor types offer distinct advantages in precision, size, and application scope, with MEMS sensors excelling in multi-axis motion detection and Hall sensors providing robust magnetic field detection.

Operating Principles: MEMS vs. Hall Sensors

MEMS sensors operate based on microelectromechanical systems that detect physical changes such as pressure, acceleration, or vibration through mechanical movement of microstructures. Hall sensors rely on the Hall effect, detecting magnetic fields by measuring voltage generated perpendicular to electric current in a conductor exposed to a magnetic field. MEMS technology offers high sensitivity to mechanical stimuli, whereas Hall sensors specialize in precise magnetic field detection for proximity and speed sensing applications.

Key Applications in Electrical Engineering

MEMS sensors are widely used in electrical engineering for precise motion detection, vibration monitoring, and inertial navigation in robotics and consumer electronics, offering high sensitivity and miniaturization. Hall sensors excel in magnetic field detection applications such as current sensing, position encoding, and speed measurement in electric motors and automotive systems due to their robustness and contactless operation. Both sensor types contribute to improving control accuracy, system efficiency, and reliability in industrial automation and smart grid technologies.

Sensitivity and Accuracy Comparison

MEMS sensors typically offer higher sensitivity due to their micro-scale mechanical structures that detect minute changes in physical parameters, making them ideal for precise measurements. Hall sensors provide reliable accuracy in detecting magnetic fields but generally have lower sensitivity compared to MEMS sensors, especially in low-field environments. The choice between MEMS and Hall sensors depends on the application requirements, with MEMS excelling in high-precision scenarios and Hall sensors favored for robust, cost-effective magnetic field detection.

Size and Integration Capabilities

MEMS sensors typically exhibit smaller form factors compared to Hall sensors, enabling more compact device integration. The microscale fabrication techniques of MEMS sensors allow seamless integration with CMOS technology, enhancing multifunctional system design. Hall sensors, while larger, are often preferred for their robustness but offer limited integration density in compact electronics.

Power Consumption Analysis

MEMS sensors generally exhibit lower power consumption compared to Hall sensors due to their microelectromechanical structure, which enables energy-efficient signal transduction. Hall sensors require a constant current to maintain sensitivity, often resulting in higher power draw, especially in continuous operation. Optimizing MEMS sensor designs for low-power applications enhances battery life in portable devices, making them preferable for energy-sensitive systems.

Response Time and Frequency Range

MEMS sensors typically offer faster response times, often in the microsecond range, enabling precise real-time measurements in dynamic environments. Hall sensors, while reliable for magnetic field detection, generally exhibit slower response times, usually in the millisecond range. MEMS sensors also support wider frequency ranges, from DC to several kilohertz up to megahertz, whereas Hall sensors are usually limited to lower frequency ranges, typically below 10 kHz.

Environmental Robustness and Reliability

MEMS sensors exhibit superior environmental robustness compared to Hall sensors due to their solid-state microfabrication, enabling resistance to shock, vibration, and temperature extremes. Their encapsulation techniques protect sensitive components from dust, moisture, and electromagnetic interference, enhancing long-term reliability in harsh conditions. Hall sensors, while effective for magnetic field detection, often require additional shielding and are more susceptible to environmental degradation and drift over time.

Cost Considerations and Market Trends

MEMS sensors generally offer lower production costs due to batch fabrication processes using semiconductor technology, making them highly cost-effective for large-scale applications. Hall sensors, while typically less expensive in raw component cost, may incur higher integration and calibration expenses in complex systems. Market trends show increasing adoption of MEMS sensors driven by demand in consumer electronics and IoT devices, while Hall sensors remain preferred for automotive and industrial applications due to their robustness and magnetic field sensitivity.

Future Prospects of MEMS and Hall Sensors

MEMS sensors are poised to dominate future markets due to their miniaturization, low power consumption, and integration capabilities with IoT devices, enabling advanced applications in automotive, healthcare, and consumer electronics. Hall sensors will continue to thrive in magnetic field detection, especially for precise current sensing and position measurement in electric vehicles and industrial automation, driven by demand for energy efficiency and smart systems. Advances in material science and signal processing are expected to enhance sensitivity and reliability for both MEMS and Hall sensors, expanding their use in emerging technologies like autonomous systems and wearable electronics.

Microelectromechanical Systems (MEMS)

Microelectromechanical Systems (MEMS) sensors offer high precision and miniaturization advantages over Hall sensors by integrating mechanical elements, sensors, actuators, and electronics on a single silicon chip.

Lorentz Force

MEMS sensors utilize mechanical deformation to detect forces, while Hall sensors measure magnetic fields through the Lorentz force acting on charge carriers in a conductor.

Capacitive Sensing

Capacitive MEMS sensors offer higher sensitivity, lower power consumption, and greater miniaturization potential compared to traditional Hall sensors for precise magnetic field detection.

Magnetoresistive Effect

MEMS sensors leveraging the magnetoresistive effect offer higher sensitivity and smaller size compared to traditional Hall sensors, enabling precise magnetic field detection in compact applications.

Anisotropic Magnetoresistance (AMR)

Anisotropic Magnetoresistance (AMR) in MEMS sensors offers higher sensitivity and miniature integration compared to traditional Hall sensors, enabling precise magnetic field detection in compact applications.

Piezoelectric Transduction

Piezoelectric transduction in MEMS sensors enables precise mechanical-to-electrical energy conversion, offering higher sensitivity and miniaturization advantages over Hall sensors, which rely on magnetic field detection.

Signal Conditioning

MEMS sensors require complex signal conditioning circuits including amplification, filtering, and temperature compensation, whereas Hall sensors typically need simpler signal conditioning primarily for offset and noise reduction.

Magnetic Flux Density

MEMS sensors offer precise magnetic flux density measurements through microfabricated structures, while Hall sensors directly detect magnetic flux density via the Hall effect, providing high sensitivity in varying magnetic field applications.

Sensitivity Drift

MEMS sensors exhibit significantly lower sensitivity drift over temperature variations compared to Hall sensors, making them more reliable for precision measurements in dynamic environments.

Offset Compensation

MEMS sensors achieve superior offset compensation through built-in temperature drift correction and calibration algorithms, whereas Hall sensors typically require external circuitry for effective offset adjustment.

MEMS sensor vs Hall sensor Infographic

njnir.com

njnir.com