Variable Frequency Drives (VFDs) control motor speed by adjusting the frequency and voltage supplied to AC motors, offering energy efficiency and smooth speed variation ideal for pumps and fans. Servo drives provide precise position, velocity, and torque control through feedback systems, making them essential for robotics and CNC machinery requiring high accuracy. Choosing between VFDs and servo drives depends on application demands, with VFDs suited for variable speed needs and servo drives for precision motion control.

Table of Comparison

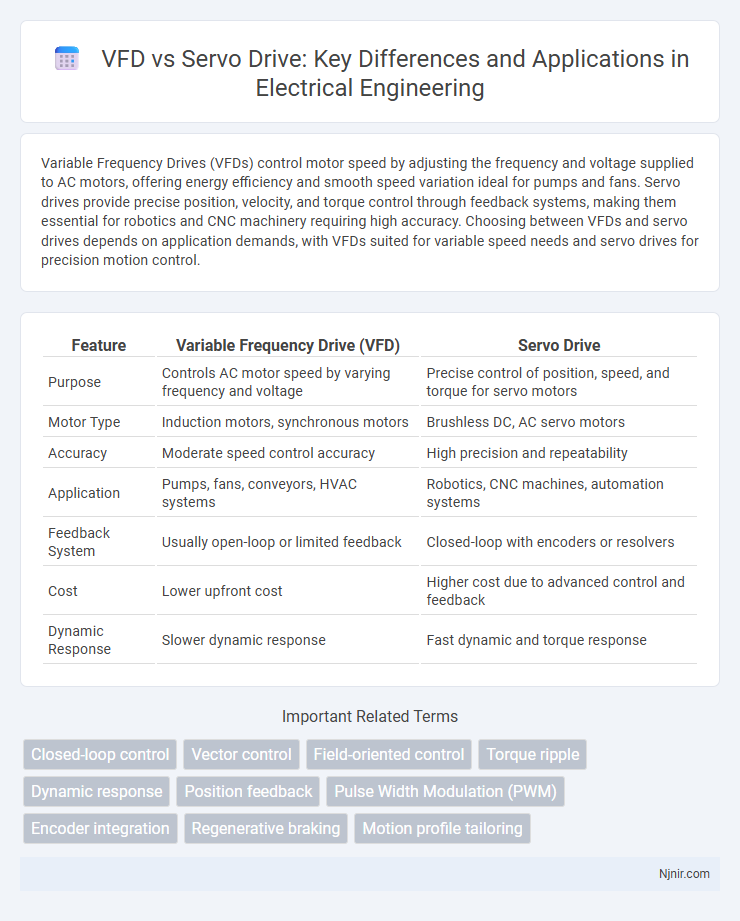

| Feature | Variable Frequency Drive (VFD) | Servo Drive |

|---|---|---|

| Purpose | Controls AC motor speed by varying frequency and voltage | Precise control of position, speed, and torque for servo motors |

| Motor Type | Induction motors, synchronous motors | Brushless DC, AC servo motors |

| Accuracy | Moderate speed control accuracy | High precision and repeatability |

| Application | Pumps, fans, conveyors, HVAC systems | Robotics, CNC machines, automation systems |

| Feedback System | Usually open-loop or limited feedback | Closed-loop with encoders or resolvers |

| Cost | Lower upfront cost | Higher cost due to advanced control and feedback |

| Dynamic Response | Slower dynamic response | Fast dynamic and torque response |

Introduction to VFDs and Servo Drives

Variable Frequency Drives (VFDs) regulate motor speed and torque by varying the frequency and voltage supplied to AC motors, primarily used for energy savings in pump, fan, and conveyor applications. Servo drives provide precise motion control by continuously adjusting the motor's position, velocity, and torque based on feedback from encoders or resolvers, essential in robotics, CNC machines, and automation systems. Understanding VFDs involves grasping their role in improving motor efficiency and process control, while servo drives emphasize accuracy and dynamic response in complex motion tasks.

Fundamental Operating Principles

Variable Frequency Drives (VFDs) control the speed of AC motors by varying the frequency and voltage supplied to the motor, enabling efficient speed regulation for applications like pumps and fans. Servo drives precisely control position, speed, and torque using feedback from encoders or resolvers, making them ideal for robotics, CNC machines, and automated manufacturing. The fundamental operating principle of VFDs is scalar control, focusing on frequency adjustment, whereas servo drives rely on closed-loop feedback systems for dynamic and accurate motor control.

Key Differences in Motion Control

VFD (Variable Frequency Drive) primarily controls AC motor speed by adjusting frequency and voltage, ideal for constant torque applications requiring smooth speed variation. Servo drives provide precise position, speed, and torque control through closed-loop feedback systems, making them essential for high-accuracy motion control in robotics and CNC machinery. Unlike VFDs, servo drives use encoders and sensors to continuously monitor motor performance, ensuring rapid response and exact motion execution.

Applications and Use Cases

Variable Frequency Drives (VFDs) are widely used in applications requiring adjustable speed control of AC motors, such as HVAC systems, pumps, and conveyors, where energy efficiency and simple speed variation are critical. Servo drives excel in precision motion control tasks found in robotics, CNC machinery, and automated manufacturing processes, offering high torque accuracy and dynamic response. Choosing between VFDs and servo drives depends largely on the application's demand for speed variability versus precise position and torque control.

Precision and Positioning Capabilities

Servo drives offer superior precision and advanced positioning capabilities compared to Variable Frequency Drives (VFDs), making them ideal for applications requiring exact motion control and repeatability. VFDs primarily control motor speed by varying frequency but lack the fine-tuned feedback mechanisms inherent in servo systems that enable precise angular positioning and rapid response to dynamic loads. For high-accuracy tasks in robotics, CNC machinery, and automation, servo drives provide closed-loop control with encoders or resolvers, ensuring exact position tracking unmatched by VFD-controlled induction motors.

Speed and Torque Control

Variable Frequency Drives (VFDs) offer efficient speed control by adjusting motor frequency and voltage, ideal for applications with moderate torque requirements and steady speed variations. Servo drives provide precise speed and torque control through closed-loop feedback systems, delivering high-performance dynamic response and accuracy essential for complex motion control tasks. For applications demanding rapid acceleration, deceleration, and synchronized torque adjustments, servo drives outperform VFDs in maintaining consistent motion precision.

Energy Efficiency Comparison

Variable Frequency Drives (VFDs) optimize motor speed by adjusting frequency and voltage, resulting in significant energy savings during variable-load operations, especially in pumping and HVAC systems. Servo drives offer precise motion control but typically consume more power due to continuous feedback and high-performance components. For applications prioritizing energy efficiency over precision, VFDs generally provide a more cost-effective and energy-saving solution.

Integration and Compatibility

VFDs (Variable Frequency Drives) offer broad compatibility with standard AC motors and straightforward integration into existing industrial systems due to their simpler control architecture. Servo drives provide advanced integration capabilities with feedback systems like encoders or resolvers, enabling precise motion control and synchronization in complex automation applications. Compatibility challenges may arise with servo drives when interfacing with older equipment not designed for closed-loop control, whereas VFDs excel in legacy system upgrades.

Cost Considerations

VFDs (Variable Frequency Drives) typically offer lower upfront costs compared to servo drives, making them ideal for applications with basic speed control requirements. Servo drives, while more expensive initially, deliver precise motion control and higher efficiency, which can reduce long-term operational costs in complex automation systems. Evaluating total cost of ownership, including maintenance and energy consumption, is crucial when comparing VFD and servo drive investments.

Choosing the Right Drive for Your Application

Choosing the right drive for your application depends on factors such as precision, control complexity, and load type. VFDs (Variable Frequency Drives) offer efficient speed control for AC motors in simple applications like pumps and fans, while servo drives provide high-precision positioning and torque control essential for robotics, CNC machines, and automation systems. Evaluate system requirements including response time, feedback mechanisms, and budget constraints to determine whether a VFD or a servo drive best matches performance needs.

Closed-loop control

Servo drives provide precise closed-loop control by continuously monitoring and adjusting motor position and speed, whereas VFDs typically operate in open-loop or sensor-less modes with less accurate feedback.

Vector control

Vector control in VFDs offers precise torque and speed regulation by controlling both magnitude and phase of motor currents, while servo drives provide superior dynamic response and position accuracy through closed-loop feedback and direct shaft position monitoring.

Field-oriented control

Field-oriented control enables servo drives to provide superior torque accuracy and dynamic response compared to VFDs, which primarily use scalar control methods.

Torque ripple

Servo drives minimize torque ripple through precise feedback control, while VFDs experience higher torque ripple due to less accurate motor current regulation.

Dynamic response

Servo drives offer superior dynamic response compared to VFDs due to their precise position and speed control with rapid acceleration and deceleration capabilities.

Position feedback

Servo drives provide precise position feedback through encoders, while VFDs typically lack direct position feedback and rely on indirect methods like motor current or sensorless estimations.

Pulse Width Modulation (PWM)

Pulse Width Modulation (PWM) in VFDs controls AC motor speed by adjusting voltage and frequency, whereas servo drives use high-frequency PWM signals for precise motor position and torque control.

Encoder integration

Servo drives require precise encoder integration for accurate position feedback, whereas VFDs typically use simpler sensorless or basic encoder inputs mainly for speed control.

Regenerative braking

Servo drives enable efficient regenerative braking by converting kinetic energy back to electrical energy for reuse, whereas VFDs typically dissipate braking energy as heat through resistors.

Motion profile tailoring

Servo drives offer superior motion profile tailoring compared to VFDs by enabling precise control of speed, position, and torque for complex, dynamic applications.

VFD vs servo drive Infographic

njnir.com

njnir.com