Litz wire significantly reduces skin and proximity effects in high-frequency electrical applications compared to solid wire, enhancing efficiency and minimizing losses. Its construction of multiple insulated strands allows improved current distribution, which is crucial in transformers, inductors, and RF circuits. Solid wire, while simpler and cheaper, struggles with increased AC resistance and heat generation at high frequencies, making it less suitable for such specialized tasks.

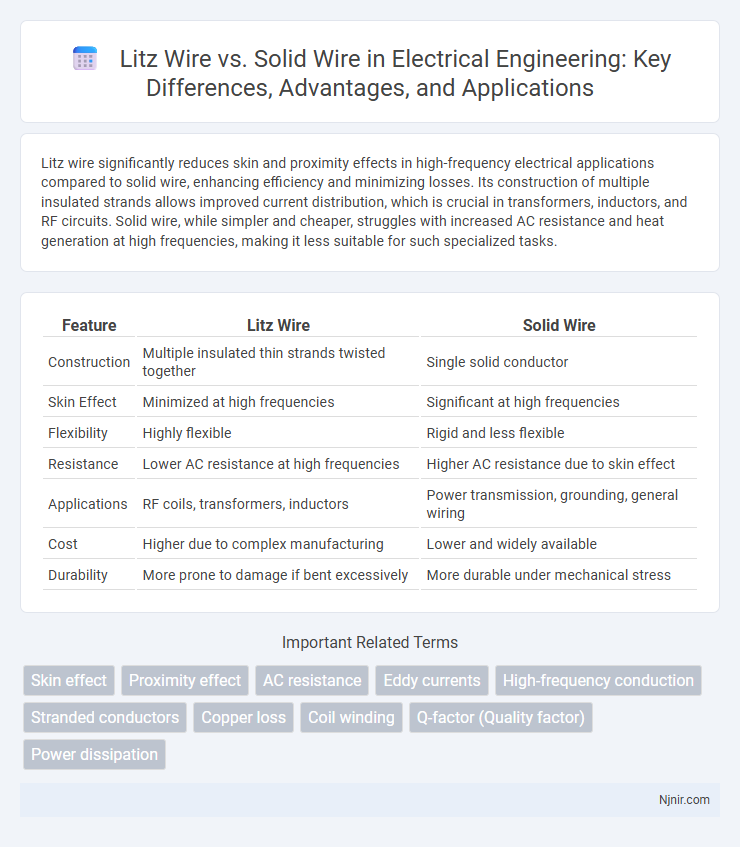

Table of Comparison

| Feature | Litz Wire | Solid Wire |

|---|---|---|

| Construction | Multiple insulated thin strands twisted together | Single solid conductor |

| Skin Effect | Minimized at high frequencies | Significant at high frequencies |

| Flexibility | Highly flexible | Rigid and less flexible |

| Resistance | Lower AC resistance at high frequencies | Higher AC resistance due to skin effect |

| Applications | RF coils, transformers, inductors | Power transmission, grounding, general wiring |

| Cost | Higher due to complex manufacturing | Lower and widely available |

| Durability | More prone to damage if bent excessively | More durable under mechanical stress |

Introduction to Litz Wire and Solid Wire

Litz wire consists of multiple individually insulated thin copper strands twisted or woven together to reduce skin effect and proximity effect losses at high frequencies, making it ideal for RF and inductive applications. Solid wire, composed of a single solid conductor, offers simplicity, mechanical strength, and lower cost but experiences higher AC resistance due to skin effect in high-frequency environments. Understanding these fundamental differences is essential for selecting the appropriate wire type in electrical and electronic design projects.

Construction and Design Differences

Litz wire consists of multiple thin, individually insulated strands woven together to reduce skin effect and proximity effect losses at high frequencies, enhancing signal transmission efficiency. Solid wire features a single, solid conductor that offers mechanical strength and lower resistance at low frequencies but suffers from increased losses in high-frequency applications due to current crowding. The multi-stranded construction of Litz wire optimizes flexibility and electromagnetic performance, while solid wire prioritizes durability and simplicity in design.

Electrical Conductivity Comparison

Litz wire exhibits superior electrical conductivity compared to solid wire at high frequencies due to its multiple insulated strands that reduce skin effect and proximity effect losses. Solid wire conductivity decreases significantly with frequency as current crowds near the surface, causing increased resistance and energy loss. The enhanced performance of Litz wire in RF applications and transformers stems from its minimized AC resistance, resulting in improved efficiency and signal integrity.

High-Frequency Performance

Litz wire significantly reduces skin effect and proximity effect losses at high frequencies due to its multiple insulated strands woven together, enhancing signal integrity in RF applications. Solid wire experiences increased resistance and signal attenuation as frequency rises because current tends to flow on the conductor's surface, limiting its efficiency in high-frequency circuits. Consequently, Litz wire is preferred in transformers, inductors, and coils operating in the kHz to MHz range, where minimizing AC resistance is critical for optimal performance.

Skin Effect and Proximity Effect

Litz wire significantly reduces the skin effect by using multiple insulated strands, increasing the effective surface area for current flow at high frequencies and minimizing AC resistance. Compared to solid wire, Litz wire also mitigates the proximity effect by distributing magnetic fields more evenly across individual strands, which decreases power losses in tightly packed coils or windings. These characteristics make Litz wire ideal for high-frequency applications such as transformers, inductors, and RF circuits where efficiency and reduced heat generation are critical.

Mechanical Flexibility and Durability

Litz wire exhibits superior mechanical flexibility compared to solid wire due to its construction of multiple thin, insulated strands twisted together, allowing it to withstand repeated bending and flexing without breaking. Solid wire tends to be less flexible and more prone to fatigue and fracture under continuous mechanical stress, making it less durable in dynamic applications. The enhanced durability of Litz wire makes it ideal for use in high-frequency, flexible environments such as winding coils in electric motors and transformers.

Applications in Electrical Engineering

Litz wire, composed of multiple thin insulated strands, is ideal for high-frequency applications such as transformers, inductors, and RF coils due to its reduced skin effect and minimized AC resistance. Solid wire, with a single conductive core, is commonly used in low-frequency and DC circuits where mechanical strength and cost-efficiency are priorities. Electrical engineers select Litz wire in precision electronics and power electronics to improve efficiency and reduce energy losses in alternating current systems.

Cost and Availability

Litz wire generally costs more than solid wire due to its complex manufacturing process involving multiple insulated strands, making it less widely available and typically found through specialized suppliers. In contrast, solid wire is more affordable and readily accessible in a variety of gauges and materials at most hardware and electronics stores. For budget-conscious projects requiring standard conductivity, solid wire remains the preferred choice, while Litz wire is reserved for applications needing reduced skin effect losses despite its higher price and limited availability.

Installation and Handling Considerations

Litz wire offers superior flexibility and reduced skin effect losses, making it ideal for complex winding installations and tight spaces compared to rigid solid wire. Its braided structure requires careful untangling and precise soldering techniques to maintain electrical integrity during installation. Solid wire is easier to handle and terminate but is prone to breakage when bent repeatedly, limiting its use in dynamic or compact applications.

Choosing Between Litz Wire and Solid Wire

Choosing between Litz wire and solid wire depends on the application's frequency and efficiency requirements. Litz wire reduces skin effect and proximity losses by using multiple insulated strands, making it ideal for high-frequency transformers, inductors, and RF coils. Solid wire offers lower resistance and mechanical strength, suited for low-frequency or DC applications where skin effect is negligible.

Skin effect

Litz wire minimizes the skin effect by using multiple insulated strands to reduce AC resistance, while solid wire experiences increased resistance at higher frequencies due to current crowding on the conductor's surface.

Proximity effect

Litz wire significantly reduces the proximity effect in high-frequency applications compared to solid wire by using multiple insulated strands to minimize eddy current losses.

AC resistance

Litz wire significantly reduces AC resistance in high-frequency applications by minimizing skin and proximity effects compared to solid wire.

Eddy currents

Litz wire significantly reduces eddy current losses compared to solid wire by using multiple insulated strands to minimize skin effect and improve efficiency in high-frequency applications.

High-frequency conduction

Litz wire reduces skin effect and proximity effect losses in high-frequency conduction, providing superior performance over solid wire in RF and high-frequency applications.

Stranded conductors

Stranded conductors like Litz wire significantly reduce skin effect and proximity losses at high frequencies compared to solid wire, improving signal integrity and efficiency in RF and high-frequency applications.

Copper loss

Litz wire significantly reduces copper loss in high-frequency applications compared to solid wire by minimizing skin effect and proximity effect losses.

Coil winding

Litz wire significantly reduces skin effect and proximity losses in high-frequency coil winding applications, improving efficiency compared to solid wire.

Q-factor (Quality factor)

Litz wire significantly improves the Q-factor in high-frequency applications by reducing skin and proximity effect losses compared to solid wire.

Power dissipation

Litz wire significantly reduces power dissipation caused by skin and proximity effects compared to solid wire, making it ideal for high-frequency applications.

Litz wire vs Solid wire Infographic

njnir.com

njnir.com