Substrate Integrated Waveguide (SIW) technology offers lower loss and higher quality factors compared to microstrip lines, making it ideal for high-frequency applications in electrical engineering. SIW provides better shielding from electromagnetic interference due to its enclosed structure, enhancing signal integrity over microstrip configurations. This results in improved performance in filters, antennas, and other microwave components where minimizing radiation loss and crosstalk is critical.

Table of Comparison

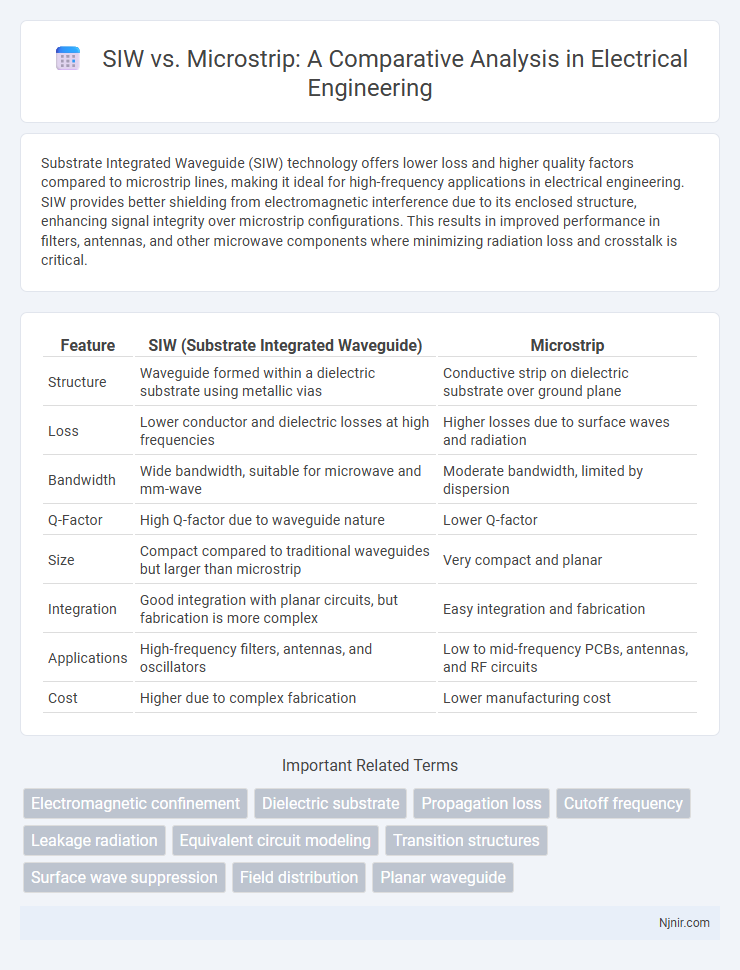

| Feature | SIW (Substrate Integrated Waveguide) | Microstrip |

|---|---|---|

| Structure | Waveguide formed within a dielectric substrate using metallic vias | Conductive strip on dielectric substrate over ground plane |

| Loss | Lower conductor and dielectric losses at high frequencies | Higher losses due to surface waves and radiation |

| Bandwidth | Wide bandwidth, suitable for microwave and mm-wave | Moderate bandwidth, limited by dispersion |

| Q-Factor | High Q-factor due to waveguide nature | Lower Q-factor |

| Size | Compact compared to traditional waveguides but larger than microstrip | Very compact and planar |

| Integration | Good integration with planar circuits, but fabrication is more complex | Easy integration and fabrication |

| Applications | High-frequency filters, antennas, and oscillators | Low to mid-frequency PCBs, antennas, and RF circuits |

| Cost | Higher due to complex fabrication | Lower manufacturing cost |

Introduction to SIW and Microstrip Technologies

Substrate Integrated Waveguide (SIW) technology combines the benefits of traditional waveguide structures with planar circuit fabrication, enabling low-loss, high-quality signal transmission in a compact form factor. Microstrip technology utilizes a planar transmission line with a conducting strip separated from a ground plane by a dielectric substrate, widely favored for its simple fabrication and compatibility with integrated circuits. Both SIW and Microstrip techniques play crucial roles in modern high-frequency and microwave circuit design, offering distinct advantages in performance, cost, and integration.

Fundamental Differences Between SIW and Microstrip

Substrate Integrated Waveguide (SIW) and microstrip differ fundamentally in their electromagnetic wave propagation mechanisms, where SIW confines waves within a dielectric substrate using metallic via arrays forming waveguide walls, resulting in low loss and high-quality factor. Microstrip employs a single conductor strip on a dielectric substrate above a ground plane, supporting quasi-TEM modes with higher radiation loss and susceptibility to environmental variations. The intrinsic shielding in SIW provides superior isolation and reduced interference compared to the more exposed field distribution in microstrip technology.

Electromagnetic Wave Propagation in SIW vs Microstrip

Substrate Integrated Waveguides (SIW) provide superior electromagnetic wave confinement and lower radiation losses compared to microstrip lines, enabling higher quality signal transmission at microwave frequencies. SIW structures support TE modes with minimal dispersion and reduced interference from substrate modes, contrasting with microstrip lines where quasi-TEM wave propagation experiences higher dielectric and conductor losses. This results in improved power handling and bandwidth efficiency for SIW in high-frequency applications compared to traditional microstrip technology.

Fabrication Techniques: SIW vs Microstrip

Substrate Integrated Waveguide (SIW) fabrication involves embedding metallic via arrays within a dielectric substrate to mimic waveguide walls, enabling high-quality factor performances and reduced radiation loss compared to traditional microstrip lines. Microstrip circuits are fabricated using standard photolithography to pattern conductive traces atop a dielectric substrate, offering simpler and cost-effective manufacturing but with higher conductor and dielectric losses at microwave frequencies. SIW fabrication demands precise drilling and plating of via holes, which increases complexity but enhances power handling and isolation, contrasting with the planar and easily customizable microstrip fabrication suited for low-cost, mass production.

Performance Comparison: Losses, Bandwidth, and Efficiency

Substrate Integrated Waveguide (SIW) exhibits lower insertion loss compared to traditional microstrip lines due to its air-filled waveguide structure, which reduces dielectric losses significantly. SIW provides wider bandwidth capabilities and improved power handling, making it more efficient for high-frequency applications like millimeter-wave systems. The enhanced confinement of electromagnetic waves in SIW results in higher radiation efficiency and reduced signal leakage relative to microstrip counterparts.

Applications of SIW and Microstrip in Modern Electronics

Substrate Integrated Waveguide (SIW) technology is extensively used in high-frequency applications such as radar systems, satellite communications, and 5G wireless networks due to its low loss and high-quality factor. Microstrip circuits dominate in compact and cost-effective designs found in smartphones, RFID tags, and IoT devices, benefiting from their planar structure and ease of fabrication. Both SIW and Microstrip play crucial roles in modern electronics, with SIW preferred for high-power, high-frequency components and Microstrip favored for flexible, low-cost circuit integration.

Integration with Other Circuit Elements: SIW vs Microstrip

Substrate Integrated Waveguide (SIW) offers superior integration with planar circuit elements due to its enclosed waveguide structure, which reduces electromagnetic interference and radiation losses compared to Microstrip lines. Microstrip, being an open transmission line, allows easier direct integration with active and passive components on the PCB but suffers from higher crosstalk and susceptibility to environmental noise. SIW's compatibility with standard PCB fabrication techniques enables seamless incorporation of filters, antennas, and amplifiers, enhancing overall system performance in compact microwave and millimeter-wave circuits.

Cost and Manufacturing Considerations

Substrate Integrated Waveguide (SIW) technology offers lower manufacturing costs compared to traditional microstrip circuits due to its compatibility with standard PCB fabrication processes and reduced material usage. Microstrip structures often require expensive high-frequency laminate materials and complex multilayer designs, increasing production expenses. SIW's use of conventional substrates results in easier mass production and better cost efficiency, especially for high-frequency and high-power applications.

Design Challenges and Limitations

Substrate Integrated Waveguide (SIW) presents design challenges including precise via hole placement and fabrication tolerance control to minimize leakage and maintain high-quality factor, which are critical for optimal performance. Microstrip lines face limitations such as higher radiation loss and lower power handling due to the exposed conductor and substrate interface, impacting bandwidth and efficiency. The integration of SIW in planar circuits requires addressing complexity in transitions and mode conversion to ensure minimal insertion loss, contrasting with the simpler but less robust microstrip configuration.

Future Trends in SIW and Microstrip Technologies

Future trends in Substrate Integrated Waveguide (SIW) and microstrip technologies emphasize enhanced integration for compact, high-frequency communication systems. SIW advancements target reduced insertion loss and improved power handling suitable for 5G/6G applications, while microstrip innovations focus on flexible, low-cost substrates enabling wearable and IoT devices. Emerging materials like graphene and metamaterials are being explored to optimize performance and bandwidth across both transmission line technologies.

Electromagnetic confinement

SIW technology offers superior electromagnetic confinement compared to microstrip lines by utilizing enclosed metallic vias that reduce radiation loss and interference.

Dielectric substrate

SIW leverages air-filled or low-loss dielectric substrates to reduce signal attenuation compared to traditional microstrip lines on higher-loss dielectric materials.

Propagation loss

SIW technology exhibits significantly lower propagation loss compared to traditional microstrip lines, primarily due to reduced conductor and dielectric losses resulting from its enclosed waveguide structure.

Cutoff frequency

Substrate Integrated Waveguide (SIW) structures typically exhibit higher cutoff frequencies and lower dispersion compared to conventional Microstrip lines, making SIW preferable for high-frequency and millimeter-wave applications.

Leakage radiation

SIW offers significantly lower leakage radiation compared to microstrip lines due to its enclosed waveguide structure and reduced electromagnetic field exposure.

Equivalent circuit modeling

SIW equivalent circuit modeling captures its resonant cavities and waveguide modes using lumped elements, while microstrip equivalent circuits emphasize distributed capacitance and inductance representing the planar transmission line characteristics.

Transition structures

SIW-to-microstrip transition structures optimize electromagnetic energy transfer by minimizing reflection and insertion loss through tapered or gradual impedance matching sections.

Surface wave suppression

Substrate Integrated Waveguide (SIW) significantly suppresses surface wave propagation compared to microstrip lines by combining waveguide-like leakage characteristics with planar circuit fabrication, resulting in lower radiation loss and enhanced signal integrity.

Field distribution

SIW offers confined electromagnetic field distribution with reduced radiation loss compared to the more dispersed field pattern in microstrip transmission lines.

Planar waveguide

Substrate Integrated Waveguide (SIW) offers lower loss, higher quality factor, and better integration with planar circuits compared to traditional microstrip lines in planar waveguide applications.

SIW vs Microstrip Infographic

njnir.com

njnir.com