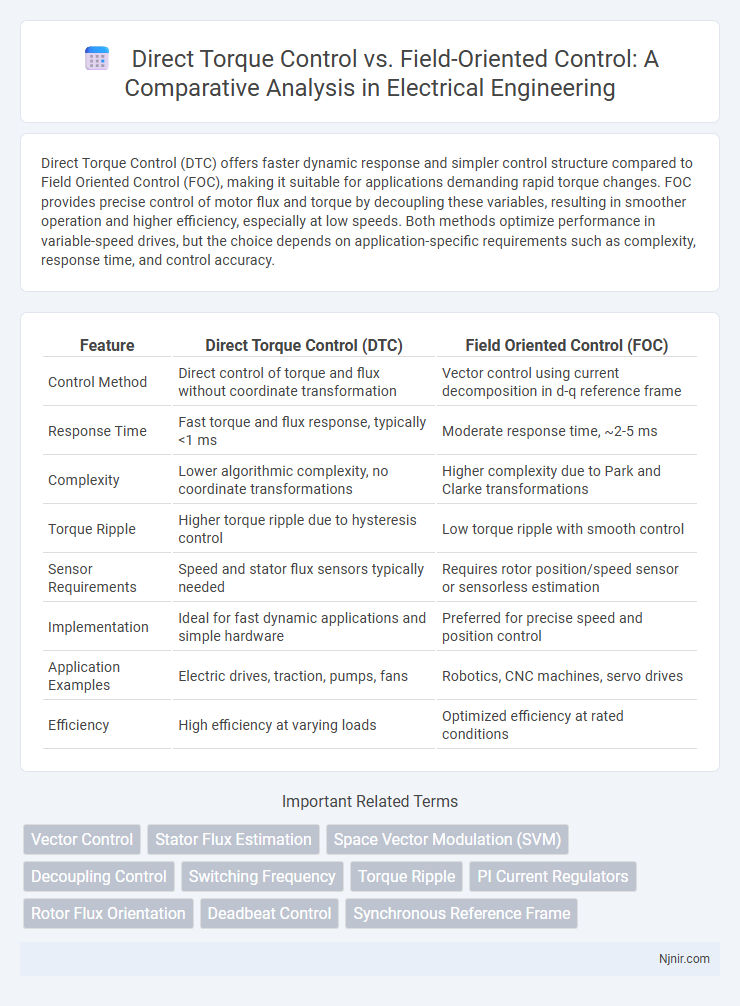

Direct Torque Control (DTC) offers faster dynamic response and simpler control structure compared to Field Oriented Control (FOC), making it suitable for applications demanding rapid torque changes. FOC provides precise control of motor flux and torque by decoupling these variables, resulting in smoother operation and higher efficiency, especially at low speeds. Both methods optimize performance in variable-speed drives, but the choice depends on application-specific requirements such as complexity, response time, and control accuracy.

Table of Comparison

| Feature | Direct Torque Control (DTC) | Field Oriented Control (FOC) |

|---|---|---|

| Control Method | Direct control of torque and flux without coordinate transformation | Vector control using current decomposition in d-q reference frame |

| Response Time | Fast torque and flux response, typically <1 ms | Moderate response time, ~2-5 ms |

| Complexity | Lower algorithmic complexity, no coordinate transformations | Higher complexity due to Park and Clarke transformations |

| Torque Ripple | Higher torque ripple due to hysteresis control | Low torque ripple with smooth control |

| Sensor Requirements | Speed and stator flux sensors typically needed | Requires rotor position/speed sensor or sensorless estimation |

| Implementation | Ideal for fast dynamic applications and simple hardware | Preferred for precise speed and position control |

| Application Examples | Electric drives, traction, pumps, fans | Robotics, CNC machines, servo drives |

| Efficiency | High efficiency at varying loads | Optimized efficiency at rated conditions |

Introduction to Modern Motor Control Techniques

Direct Torque Control (DTC) and Field Oriented Control (FOC) are advanced strategies used to precisely control electric motor torque and speed in various industrial applications. DTC offers rapid torque response with simpler control structure by directly regulating torque and flux without requiring coordinate transformation. FOC enhances motor efficiency and dynamic performance by decoupling torque and flux control through coordinate transformations, enabling smooth and accurate motor operation particularly in applications demanding high precision.

Fundamentals of Direct Torque Control (DTC)

Direct Torque Control (DTC) fundamentally relies on the rapid and precise regulation of stator flux and electromagnetic torque by directly selecting voltage vectors based on hysteresis comparators and a switching table, bypassing the need for coordinate transformations used in Field Oriented Control (FOC). The core principle involves estimating the stator flux linkage and torque from motor currents and voltages, followed by determining the optimal inverter switching states to maintain torque and flux within predefined hysteresis bands. This approach enables fast dynamic response and reduced computational complexity, making DTC advantageous for applications requiring high torque accuracy and robustness under varying load conditions.

Fundamentals of Field Oriented Control (FOC)

Field Oriented Control (FOC) achieves precise motor control by decoupling torque and flux components in AC motors through coordinate transformations, enabling independent control similar to a DC motor. It uses Clarke and Park transforms to convert stator currents into a rotating reference frame aligned with the rotor flux, facilitating effective modulation of motor torque and speed. FOC provides enhanced dynamic performance and efficiency compared to Direct Torque Control by maintaining constant flux magnitude and controlling torque-producing current directly.

Working Principles: DTC vs FOC

Direct Torque Control (DTC) regulates motor torque and flux by selecting voltage vectors based on instantaneous errors using a hysteresis controller, enabling fast dynamic response without requiring coordinate transformation. Field Oriented Control (FOC) employs coordinate transformation of stator currents into a rotating reference frame aligned with the rotor flux, enabling independent control of torque and flux components via PID controllers for precise motor operation. DTC offers faster torque response and simpler control structure while FOC provides smoother torque control and better steady-state performance.

Control Architecture Comparison

Direct Torque Control (DTC) employs a control architecture centered on direct manipulation of motor torque and flux using predefined switching states of the inverter, resulting in a fast dynamic response without the need for complex coordinate transformations. Field Oriented Control (FOC) relies on a vector control architecture that decouples torque and flux by transforming stator currents into a rotating reference frame using Park and Clarke transformations, enabling precise control through independent current regulators. DTC offers simpler implementation with fewer sensors, while FOC provides superior steady-state control accuracy and smoother torque output due to continuous current control.

Performance in Dynamic Response

Direct Torque Control (DTC) offers faster dynamic response and superior torque control compared to Field Oriented Control (FOC), making it highly efficient for applications requiring rapid torque changes. DTC minimizes torque ripple and reduces the response time to load disturbances due to its direct manipulation of flux and torque. In contrast, FOC provides smoother operation but typically exhibits slower dynamic performance because of its reliance on coordinate transformation and current regulators.

Efficiency and Energy Consumption

Direct Torque Control (DTC) offers faster dynamic response and reduced switching losses, leading to improved efficiency in electric motor drives compared to Field Oriented Control (FOC). DTC minimizes energy consumption by directly controlling torque and flux without requiring complex coordinate transformations, which reduces computational load and inverter switching frequency. Field Oriented Control achieves high precision in torque and speed regulation but typically involves higher switching losses and slightly increased energy usage due to continuous modulation processes.

Implementation Complexity and Hardware Requirements

Direct Torque Control (DTC) typically demands simpler hardware with fewer sensors and eliminates the need for pulse-width modulation, reducing implementation complexity. Field Oriented Control (FOC) relies on precise rotor position sensors and sophisticated transformations, leading to higher hardware costs and more complex software algorithms. While DTC offers faster dynamic response with less computational burden, FOC provides smoother torque control at the expense of increased implementation complexity and hardware requirements.

Applications: Industrial Use Cases

Direct Torque Control (DTC) excels in applications requiring rapid torque response and precise control, such as steel rolling mills and electric vehicle traction systems where dynamic load changes occur frequently. Field Oriented Control (FOC) is widely used in industrial automation and robotics due to its smooth and efficient motor operation, making it ideal for conveyors, CNC machines, and HVAC systems. Both control methods optimize energy consumption and motor performance, but DTC is preferred for high dynamic performance, whereas FOC is favored for steady-state efficiency and noise reduction.

Future Trends in Motor Drive Control

Future trends in motor drive control emphasize the integration of Artificial Intelligence with Direct Torque Control (DTC) to enhance real-time torque precision and reduce switching losses. Advances in sensor technology and machine learning algorithms are driving the evolution of Field Oriented Control (FOC) towards adaptive parameter tuning for improved efficiency in variable load conditions. The convergence of IoT connectivity with DTC and FOC techniques is enabling predictive maintenance and energy-optimized performance in industrial motor drives.

Vector Control

Direct Torque Control achieves faster dynamic response and simpler implementation by directly regulating torque and flux, while Field Oriented Control precisely decouples torque and flux components through coordinate transformation for smoother and more efficient vector control of AC motors.

Stator Flux Estimation

Direct Torque Control achieves faster and more accurate stator flux estimation by directly controlling flux vectors, whereas Field Oriented Control relies on coordinate transformations and sensor feedback for stator flux calculation.

Space Vector Modulation (SVM)

Direct Torque Control achieves faster torque response by directly controlling stator flux using hysteresis comparators, while Field Oriented Control combined with Space Vector Modulation ensures precise voltage vector synthesis for smooth motor operation and reduced torque ripple.

Decoupling Control

Direct Torque Control (DTC) achieves faster dynamic response and simpler implementation by directly controlling torque and flux without requiring coordinate transformation, whereas Field Oriented Control (FOC) decouples torque and flux components using coordinate transformation for precise and independent control of motor currents.

Switching Frequency

Direct Torque Control offers lower switching frequency compared to Field Oriented Control, resulting in reduced switching losses and improved inverter efficiency.

Torque Ripple

Direct Torque Control offers lower torque ripple compared to Field Oriented Control by directly regulating torque and flux with faster dynamic response.

PI Current Regulators

Direct Torque Control offers faster dynamic response than Field Oriented Control but requires more complex PI current regulator tuning for optimal torque and flux control.

Rotor Flux Orientation

Direct Torque Control (DTC) offers faster dynamic response by directly controlling rotor flux orientation without requiring coordinate transformations, whereas Field Oriented Control (FOC) relies on precise rotor flux alignment through Park and Clarke transformations for efficient torque and flux decoupling.

Deadbeat Control

Deadbeat Control in Direct Torque Control (DTC) offers faster dynamic response and simpler implementation compared to Field Oriented Control (FOC), which prioritizes precise torque and flux regulation through coordinate transformations.

Synchronous Reference Frame

Direct Torque Control achieves faster torque response by directly manipulating stator flux and torque in the synchronous reference frame, while Field Oriented Control uses coordinate transformation to independently control flux and torque components for precise motor performance.

Direct Torque Control vs Field Oriented Control Infographic

njnir.com

njnir.com