Smokeless motors use advanced materials and design to eliminate smoke production, enhancing environmental safety and reducing maintenance. Carbon brush motors rely on physical contact between brushes and the commutator, which generates friction, heat, and smoke during operation. Smokeless technology improves motor longevity and efficiency by minimizing wear and particulate emissions compared to traditional carbon brush systems.

Table of Comparison

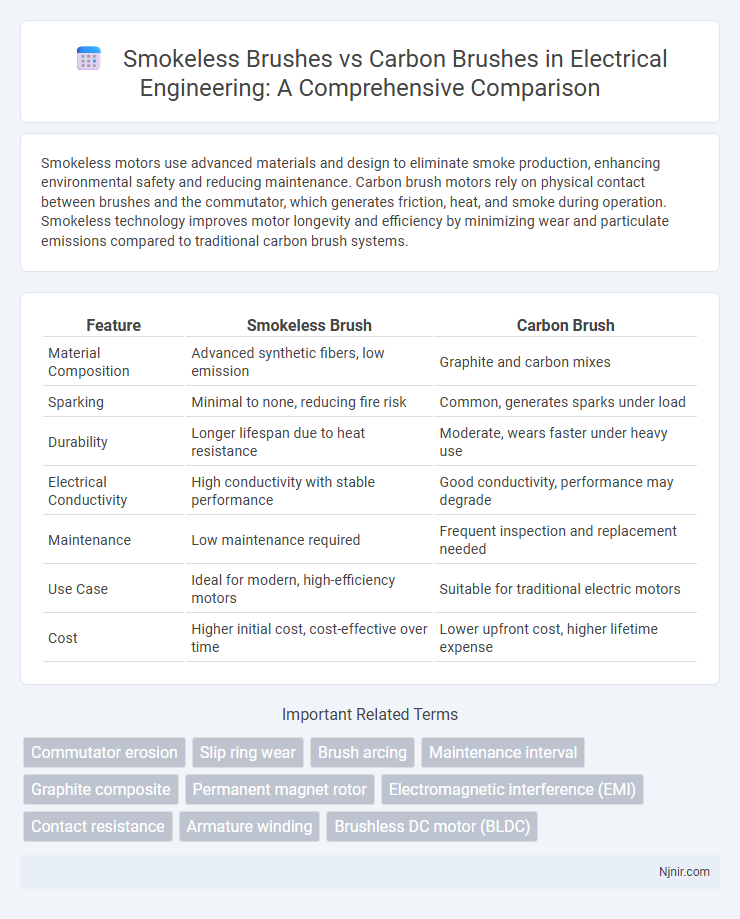

| Feature | Smokeless Brush | Carbon Brush |

|---|---|---|

| Material Composition | Advanced synthetic fibers, low emission | Graphite and carbon mixes |

| Sparking | Minimal to none, reducing fire risk | Common, generates sparks under load |

| Durability | Longer lifespan due to heat resistance | Moderate, wears faster under heavy use |

| Electrical Conductivity | High conductivity with stable performance | Good conductivity, performance may degrade |

| Maintenance | Low maintenance required | Frequent inspection and replacement needed |

| Use Case | Ideal for modern, high-efficiency motors | Suitable for traditional electric motors |

| Cost | Higher initial cost, cost-effective over time | Lower upfront cost, higher lifetime expense |

Introduction to Smokeless and Carbon Brushes

Smokeless brushes use advanced composite materials that reduce friction and wear, resulting in cleaner operation with minimal residue, ideal for high-performance electrical motors. Carbon brushes are traditionally made from natural carbon or graphite, providing reliable conductivity and durability but producing visible dust during use. Selecting between smokeless and carbon brushes depends on specific motor requirements, maintenance preferences, and environmental considerations.

Working Principles of Brush Technologies

Smokeless motor brushes operate using advanced composite materials that reduce sparking and heat generation during electrical contact, enhancing efficiency and lifespan in high-performance applications. Carbon brushes function by conducting current through a sliding contact with the commutator, utilizing soft carbon to maintain electrical connection while minimizing wear and friction. The key difference lies in smokeless technology's ability to minimize carbon dust emission, improving environmental safety and motor reliability compared to traditional carbon brush systems.

Material Composition Comparison

Smokeless motors typically use advanced composite materials such as high-grade ceramics and rare earth magnets, which enhance durability and thermal efficiency. Carbon brushes, on the other hand, are primarily made from a mixture of carbon and graphite, designed for electrical conductivity and wear resistance. The key material difference lies in smokeless motors' innovative composites that reduce sparking, whereas carbon brushes rely on traditional carbon-based materials for contact and conductivity.

Efficiency in Electrical Machines

Smokeless motors offer higher efficiency in electrical machines due to reduced sparking and minimal energy loss compared to carbon brush motors, which experience friction and wear from brush contact. The absence of brushes in smokeless designs leads to lower maintenance costs and longer operational life, enhancing overall machine reliability. Carbon brush motors generally have lower efficiency because of electrical resistance and mechanical drag caused by brush-commutator interaction.

Maintenance and Longevity

Smokeless motors typically require less maintenance due to the absence of carbon brushes, which eliminates frequent brush replacements and reduces wear on the commutator. Carbon brush motors demand regular inspection and replacement of brushes to maintain optimal performance, often resulting in shorter overall motor lifespan. The brushless design significantly enhances longevity by minimizing friction and electrical wear components.

Performance in Varying Load Conditions

Smokeless motors maintain consistent torque and operational efficiency under varying load conditions due to their advanced brushless design, minimizing power loss and heat generation. Carbon brush motors experience voltage drops and performance fluctuations as brushes wear and create friction, leading to reduced efficiency under heavy or fluctuating loads. Smokeless motors offer superior durability and stable performance, making them ideal for applications requiring reliable operation across diverse load scenarios.

Environmental Impact and Emissions

Smokeless motors generate significantly lower emissions compared to carbon brush motors, reducing air pollution and contributing to improved environmental health. Carbon brush motors produce particulate matter and greenhouse gases due to friction and wear, leading to higher environmental degradation. The adoption of smokeless technology supports sustainability goals by minimizing carbon footprint and operational waste.

Cost Analysis and Life Cycle

Smokeless motors generally have a higher upfront cost due to advanced materials and technology compared to traditional carbon brush motors, which are more economical initially but incur frequent maintenance expenses from brush replacements. The life cycle of smokeless motors is significantly longer, often doubling that of carbon brush motors, leading to reduced downtime and lower total ownership costs over time. Maintenance costs for carbon brush motors accumulate quickly, making smokeless alternatives more cost-effective in intensive or long-term applications despite the initial investment.

Industry Applications and Suitability

Smokeless motors, leveraging brushless technology, offer enhanced efficiency and reduced maintenance, making them ideal for industries like HVAC, robotics, and medical equipment requiring long service life and low noise. Carbon brush motors remain suitable for heavy-duty applications such as construction machinery and power tools due to their simplicity, cost-effectiveness, and ability to handle high torque. Selecting between smokeless and carbon brush motors depends on specific industrial requirements like operational environment, maintenance capacity, and power demands.

Future Trends in Brush Technology

Brush technology is rapidly evolving with future trends favoring smokeless designs due to their enhanced efficiency and reduced environmental impact. Carbon brushes, although widely used for their conductivity and durability, face challenges from wear and maintenance requirements, leading to a gradual shift toward advanced composite and graphene-based alternatives. Innovations in materials and manufacturing processes aim to extend lifespan and improve performance, positioning smokeless brushes as a key development in sustainable industrial applications.

Commutator erosion

Brushless motors significantly reduce commutator erosion compared to carbon brush motors by eliminating physical contact and sparking during operation.

Slip ring wear

Slip ring wear occurs more frequently in carbon brush systems due to increased friction, while smokeless brushes minimize wear by reducing contact degradation.

Brush arcing

Brush arcing occurs more frequently in carbon brushes due to increased friction and wear, whereas smokeless brushes significantly reduce arcing by maintaining consistent electrical contact and minimizing carbon dust.

Maintenance interval

Brushless motors have significantly longer maintenance intervals compared to carbon brush motors due to the absence of brushes that wear out and require regular replacement.

Graphite composite

Graphite composite carbon brushes provide superior conductivity and wear resistance compared to smokeless carbon brushes, enhancing electric motor performance and lifespan.

Permanent magnet rotor

Permanent magnet rotor motors with smokeless design offer higher efficiency and lower maintenance compared to traditional carbon brush systems by eliminating brush wear and sparking.

Electromagnetic interference (EMI)

Brushless motors generate significantly less electromagnetic interference (EMI) compared to carbon brush motors, enhancing performance in sensitive electronic applications.

Contact resistance

Brushless motors feature significantly lower contact resistance compared to carbon brush motors, resulting in improved efficiency and reduced power loss.

Armature winding

Smokeless armature winding enhances efficiency and reduces maintenance by eliminating carbon brush wear and sparking compared to traditional carbon brush armatures.

Brushless DC motor (BLDC)

Brushless DC motors (BLDC) outperform carbon brush motors by offering higher efficiency, lower maintenance, longer lifespan, and reduced electrical noise due to the absence of brushes.

Smokeless vs Carbon brush Infographic

njnir.com

njnir.com