Fiber optic sensors offer superior sensitivity and immunity to electromagnetic interference compared to capacitive sensors, making them ideal for precise measurements in harsh electrical environments. Capacitive sensors excel at detecting changes in capacitance due to their simple design and cost-effectiveness, commonly used for proximity and humidity sensing. The choice between fiber optic and capacitive sensors depends on application requirements such as measurement accuracy, environmental conditions, and integration complexity.

Table of Comparison

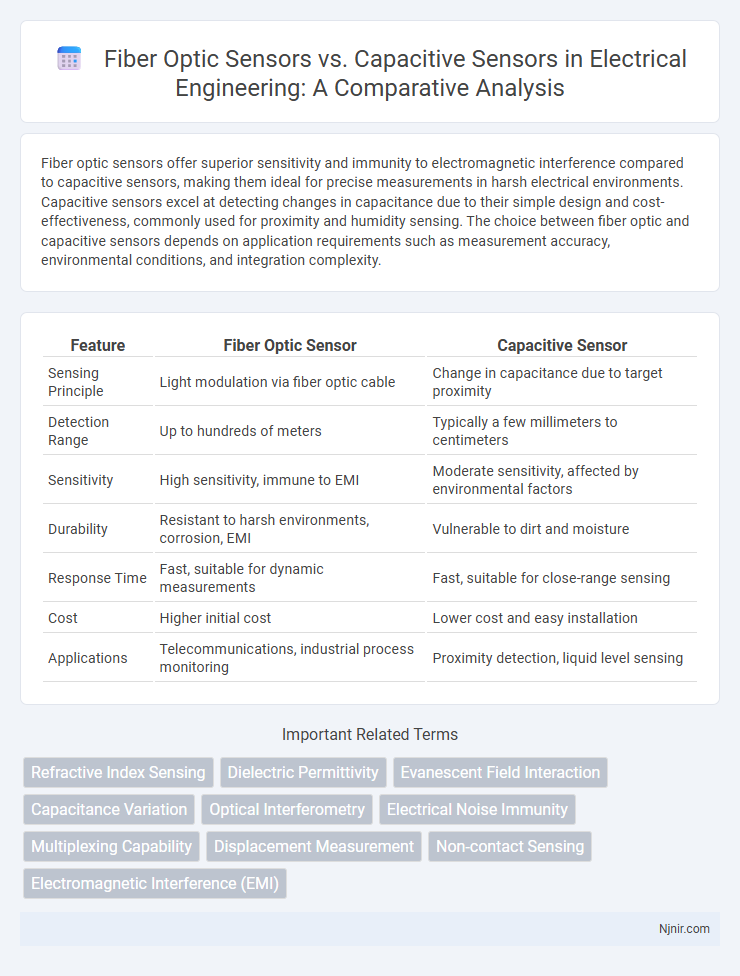

| Feature | Fiber Optic Sensor | Capacitive Sensor |

|---|---|---|

| Sensing Principle | Light modulation via fiber optic cable | Change in capacitance due to target proximity |

| Detection Range | Up to hundreds of meters | Typically a few millimeters to centimeters |

| Sensitivity | High sensitivity, immune to EMI | Moderate sensitivity, affected by environmental factors |

| Durability | Resistant to harsh environments, corrosion, EMI | Vulnerable to dirt and moisture |

| Response Time | Fast, suitable for dynamic measurements | Fast, suitable for close-range sensing |

| Cost | Higher initial cost | Lower cost and easy installation |

| Applications | Telecommunications, industrial process monitoring | Proximity detection, liquid level sensing |

Introduction to Fiber Optic and Capacitive Sensors

Fiber optic sensors utilize light transmission through optical fibers to detect changes in temperature, pressure, or strain with high sensitivity and immunity to electromagnetic interference. Capacitive sensors measure changes in capacitance caused by the proximity or material properties of an object, offering precise detection in touchscreens, humidity sensors, and level measurement applications. Both sensor types enable accurate monitoring, but fiber optic sensors excel in harsh environments while capacitive sensors provide fast, cost-effective solutions for surface and object detection.

Working Principles: Fiber Optic vs Capacitive Sensors

Fiber optic sensors operate by detecting changes in light transmission caused by external physical parameters such as temperature, pressure, or strain, using optical fibers that transmit light signals. Capacitive sensors function based on variations in capacitance caused by the proximity or presence of objects, where the sensor measures changes in the electric field between conductive plates. The working principle of fiber optic sensors enables high sensitivity and immunity to electromagnetic interference, whereas capacitive sensors excel in detecting material properties and object positions through changes in dielectric constants.

Key Components and Construction

Fiber optic sensors utilize optical fibers as their key components, where light transmission changes based on external stimuli such as temperature, pressure, or strain, enabling precise measurement. Capacitive sensors consist primarily of conductive plates separated by a dielectric material, detecting variations in capacitance caused by changes in proximity, pressure, or humidity. The construction of fiber optic sensors involves a light source, optical fibers, and photodetectors, while capacitive sensors are built with electrodes, dielectrics, and signal processing circuits.

Sensitivity and Accuracy Comparison

Fiber optic sensors exhibit higher sensitivity due to their ability to detect minute changes in light signals caused by environmental variations, making them ideal for precise measurements in complex settings. Capacitive sensors offer excellent accuracy in detecting changes in capacitance related to material properties or proximity but may suffer from interference in electrically noisy environments. Comparing the two, fiber optic sensors deliver superior sensitivity and consistent accuracy over longer distances, while capacitive sensors provide reliable accuracy in short-range applications with conductive or dielectric materials.

Environmental and Operational Suitability

Fiber optic sensors excel in harsh environments due to their immunity to electromagnetic interference, high temperature tolerance up to 1000degC, and resistance to corrosion, making them ideal for explosive or chemically aggressive settings. Capacitive sensors offer reliable performance in clean, low-moisture environments but can experience signal degradation when exposed to dust, moisture, or conductive contaminants. Operational suitability favors fiber optic sensors in high-vibration, electrically noisy industries like aerospace and oil and gas, while capacitive sensors are preferred for simple proximity detection in controlled industrial automation and consumer electronics.

Installation and Maintenance Requirements

Fiber optic sensors require precise alignment and protection from physical damage during installation, often involving specialized connectors and careful handling of delicate fibers. Maintenance demands periodic inspections for fiber integrity and cleaning of optical interfaces to prevent signal loss, with minimal electrical interference concerns. Capacitive sensors offer easier installation with standard wiring and mounting but need regular calibration and cleaning of sensing surfaces to maintain accuracy, particularly in environments with dust or moisture.

Cost Analysis: Initial and Long-Term

Fiber optic sensors generally have higher initial costs due to advanced materials and installation complexity, but offer lower long-term maintenance expenses and resilience in harsh environments. Capacitive sensors are cost-effective initially with simpler installation and components but may require more frequent replacements or calibration, increasing total lifetime costs. Evaluating the total cost of ownership highlights fiber optic sensors' advantage in durability and reduced operational disruptions over time.

Applications in Electrical Engineering

Fiber optic sensors excel in high-voltage and electromagnetic interference-prone environments due to their immunity to electromagnetic noise, making them ideal for power grid monitoring and high-frequency signal detection. Capacitive sensors are widely used in touch panels, humidity detection, and proximity sensing in electrical devices because of their sensitivity to changes in dielectric properties and ability to measure small displacements. Both sensor types contribute significantly to automation, fault detection, and control systems in modern electrical engineering applications.

Advantages and Limitations

Fiber optic sensors offer high sensitivity, immunity to electromagnetic interference, and the ability to operate in harsh environments, making them ideal for applications requiring precise measurements over long distances. Capacitive sensors provide excellent resolution and fast response times, making them suitable for detecting changes in proximity, humidity, or material composition in compact and cost-effective designs. Fiber optic sensors are limited by higher initial costs and complexity in installation, while capacitive sensors can be affected by environmental factors such as dust, moisture, and temperature variations, which may reduce accuracy.

Future Trends and Emerging Technologies

Fiber optic sensors are advancing with innovations in integrated photonics and AI-driven signal processing, enabling enhanced sensitivity and real-time monitoring in harsh environments. Capacitive sensors are evolving through the integration of flexible electronics and nanomaterials, promoting wearables and IoT applications with improved accuracy and miniaturization. Future trends emphasize hybrid sensing platforms that combine fiber optic and capacitive technologies to leverage the strengths of both for smart infrastructure and healthcare diagnostics.

Refractive Index Sensing

Fiber optic sensors offer higher sensitivity and broader measurement range for refractive index sensing compared to capacitive sensors, making them more suitable for precise optical parameter detection.

Dielectric Permittivity

Fiber optic sensors exhibit higher sensitivity to changes in dielectric permittivity compared to capacitive sensors, enabling more precise detection in environments with varying material properties.

Evanescent Field Interaction

Evanescent field interaction in fiber optic sensors enables high-sensitivity detection through light wave attenuation near the fiber surface, whereas capacitive sensors rely on changes in dielectric properties to measure variations without direct optical interaction.

Capacitance Variation

Fiber optic sensors detect changes in light properties for measurement, while capacitive sensors specifically measure capacitance variation caused by changes in dielectric material or geometry.

Optical Interferometry

Fiber optic sensors utilizing optical interferometry offer higher sensitivity and immunity to electromagnetic interference compared to capacitive sensors, making them ideal for precise displacement and vibration measurements in harsh environments.

Electrical Noise Immunity

Fiber optic sensors provide superior electrical noise immunity compared to capacitive sensors, making them ideal for environments with high electromagnetic interference.

Multiplexing Capability

Fiber optic sensors excel in multiplexing capability by allowing multiple sensing points along a single fiber, whereas capacitive sensors typically require separate wiring for each sensor, limiting their scalability in complex applications.

Displacement Measurement

Fiber optic sensors provide higher precision and immunity to electromagnetic interference in displacement measurement compared to capacitive sensors, which are more cost-effective but sensitive to environmental conditions.

Non-contact Sensing

Fiber optic sensors enable high-precision non-contact sensing with immunity to electromagnetic interference, while capacitive sensors detect proximity based on changes in capacitance but may be affected by environmental factors.

Electromagnetic Interference (EMI)

Fiber optic sensors are immune to electromagnetic interference (EMI), making them ideal for environments with high EMI, whereas capacitive sensors are susceptible to EMI, which can cause signal distortion and reduce accuracy.

Fiber optic sensor vs Capacitive sensor Infographic

njnir.com

njnir.com