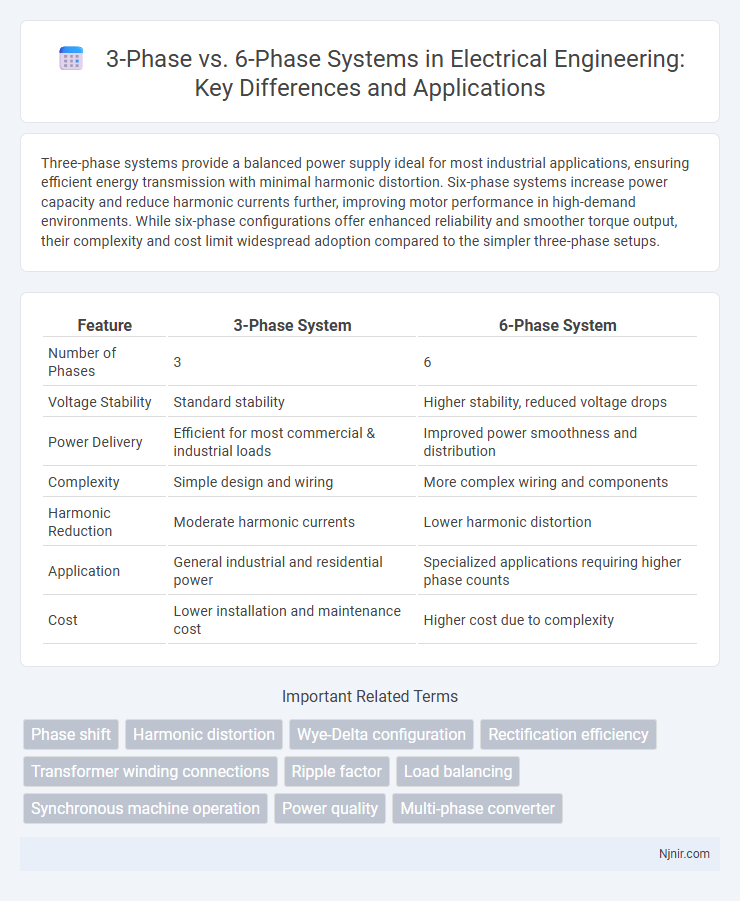

Three-phase systems provide a balanced power supply ideal for most industrial applications, ensuring efficient energy transmission with minimal harmonic distortion. Six-phase systems increase power capacity and reduce harmonic currents further, improving motor performance in high-demand environments. While six-phase configurations offer enhanced reliability and smoother torque output, their complexity and cost limit widespread adoption compared to the simpler three-phase setups.

Table of Comparison

| Feature | 3-Phase System | 6-Phase System |

|---|---|---|

| Number of Phases | 3 | 6 |

| Voltage Stability | Standard stability | Higher stability, reduced voltage drops |

| Power Delivery | Efficient for most commercial & industrial loads | Improved power smoothness and distribution |

| Complexity | Simple design and wiring | More complex wiring and components |

| Harmonic Reduction | Moderate harmonic currents | Lower harmonic distortion |

| Application | General industrial and residential power | Specialized applications requiring higher phase counts |

| Cost | Lower installation and maintenance cost | Higher cost due to complexity |

Introduction to Polyphase Systems

Polyphase systems enhance electrical power transmission by distributing power through multiple alternating current (AC) phases, improving efficiency and stability. In 3-phase systems, three alternating currents are set 120 degrees apart, providing a constant power flow suitable for most industrial and commercial applications. Six-phase systems double the number of phases, reducing torque pulsations and improving power quality, often used in specialized high-voltage or high-power contexts.

Fundamental Principles of 3-Phase and 6-Phase Power

Three-phase power systems use three alternating currents, each 120 degrees out of phase, providing a constant transfer of power and efficient energy distribution. Six-phase power systems, essentially doubling the number of phases, split the power cycles into six 60-degree intervals, reducing harmonic distortion and improving voltage stability in complex applications. The fundamental principle of six-phase systems enhances power quality and reliability compared to the simpler three-phase configuration by ensuring smoother current flow and reduced electrical stress on components.

Historical Development and Applications

The development of 3-phase power systems dates back to the late 19th century, pioneered by Nikola Tesla for efficient electrical power transmission and distribution, becoming the global standard for industrial and commercial applications due to its simplicity and reliability. The 6-phase system evolved later as an extension to reduce harmonic distortion and improve power quality in specialized applications such as high-voltage direct current (HVDC) transmission and multi-pulse rectification in power electronics. While 3-phase systems dominate general power delivery, 6-phase configurations are crucial in advanced electrical engineering contexts that require enhanced efficiency, smoother waveform generation, and reduced electrical losses.

Electrical Characteristics: Voltage, Current, and Power

Three-phase systems provide balanced voltage and current with a phase difference of 120 degrees, ensuring a constant power flow and efficient operation in industrial applications. Six-phase systems, created by doubling the number of phases, offer smoother voltage waveforms with reduced harmonic distortion and lower pulsating torque, enhancing power quality and machine performance. While voltage levels remain similar, six-phase configurations distribute current more evenly, resulting in improved power handling and reduced electrical stress on components.

System Configuration and Wiring Differences

3-phase systems utilize three conductors carrying alternating currents separated by 120 electrical degrees, creating a balanced power load and standard wiring configurations such as delta or wye connections. In contrast, 6-phase systems double the phase count to six conductors, each spaced by 60 electrical degrees, enabling smoother waveform output, reduced harmonic distortion, and enhanced power quality. Wiring complexity increases in 6-phase systems, requiring advanced insulation and specialized transformers to manage the additional phases and maintain system stability.

Benefits of 3-Phase Systems

3-phase systems deliver consistent power with reduced voltage variation, resulting in enhanced efficiency for industrial motors and large electrical loads. They require less conductor material compared to equivalent single-phase or higher-phase systems, leading to cost savings in installation and maintenance. Improved power quality and smoother operation of equipment in 3-phase systems minimize downtime and extend the lifespan of machinery.

Advantages of 6-Phase Systems

6-phase systems offer improved power density and reduced harmonic distortion compared to traditional 3-phase systems, leading to enhanced electrical efficiency and smoother power delivery. They provide greater fault tolerance and redundancy, allowing for continued operation even if one phase fails, which is critical in industrial applications and power grids. Additionally, 6-phase configurations enable the use of smaller and more economical transformers and conductors, reducing overall infrastructure costs and maintenance requirements.

Efficiency, Harmonic Reduction, and Power Quality

6-phase systems typically offer higher efficiency than 3-phase systems by reducing losses through better load distribution and lower current per phase. Harmonic reduction is significantly improved in 6-phase configurations due to phase displacement and increased pulse number, which leads to smoother waveforms and less distortion. Enhanced power quality in 6-phase systems results from diminished harmonic content and balanced voltages, promoting increased reliability and reduced equipment stress.

Industrial and Utility Sector Applications

In industrial and utility sectors, 3-phase systems are widely employed due to their efficiency in power transmission, balanced load distribution, and compatibility with standard motors and equipment. However, 6-phase systems offer enhanced power quality, reduced harmonic distortion, and improved fault tolerance, making them suitable for specialized applications requiring higher reliability and power capacity. Implementing 6-phase configurations can lead to more compact transformer designs and reduced conductor costs in large-scale utilities, although 3-phase remains dominant for general industrial use.

Comparative Analysis: Selecting the Right Phase System

Three-phase systems provide balanced power delivery with minimal harmonic distortion, ideal for standard industrial and commercial applications due to their efficiency and simplicity. Six-phase systems, offering improved power quality and reduced voltage ripple, are advantageous in high-power and specialized machinery scenarios where enhanced performance and reduced electromagnetic interference are critical. Choosing between three-phase and six-phase depends on factors such as load characteristics, equipment requirements, and cost considerations, with six-phase systems often reserved for complex applications demanding greater precision and stability.

Phase shift

A 6-phase system produces a 60-degree phase shift between each phase, reducing harmonic distortion compared to the 120-degree phase shift in a 3-phase system.

Harmonic distortion

6-phase power systems reduce harmonic distortion significantly compared to 3-phase systems by providing smoother current waveforms and improved power quality.

Wye-Delta configuration

The 3-phase Wye-Delta configuration offers simpler design and cost-effectiveness, while the 6-phase system provides improved power quality and reduced harmonic distortion in industrial applications.

Rectification efficiency

A 6-phase rectifier offers higher rectification efficiency than a 3-phase rectifier by reducing ripple current and improving output voltage quality.

Transformer winding connections

3-phase transformers use three windings spaced 120deg apart for balanced power distribution, while 6-phase transformers employ six windings spaced 60deg apart to reduce harmonic distortion and improve voltage regulation.

Ripple factor

A 6-phase rectifier significantly reduces ripple factor compared to a 3-phase rectifier, enhancing output voltage smoothness and improving power quality in electrical systems.

Load balancing

A 6-phase system offers superior load balancing compared to a 3-phase system by distributing electrical loads more evenly across phases, reducing voltage fluctuations and minimizing harmonic distortion in power delivery.

Synchronous machine operation

A 6-phase synchronous machine offers improved torque ripple reduction, enhanced fault tolerance, and smoother operation compared to a traditional 3-phase synchronous machine.

Power quality

A 6-phase power system significantly improves power quality by reducing harmonic distortion and providing smoother voltage and current waveforms compared to a 3-phase system.

Multi-phase converter

Multi-phase converters with 6 phases improve power density and reduce output voltage ripple compared to 3-phase designs, enhancing efficiency and performance in power electronics.

3-phase vs 6-phase Infographic

njnir.com

njnir.com