Brushless motors offer higher efficiency and reduced maintenance compared to brushed motors due to the absence of physical brushes that cause friction and wear. Brush motors rely on mechanical brushes to conduct current, leading to increased heat generation and potential sparking, which limits their lifespan. Brushless designs utilize electronic commutation to deliver precise control and improved performance, making them ideal for modern electrical engineering applications.

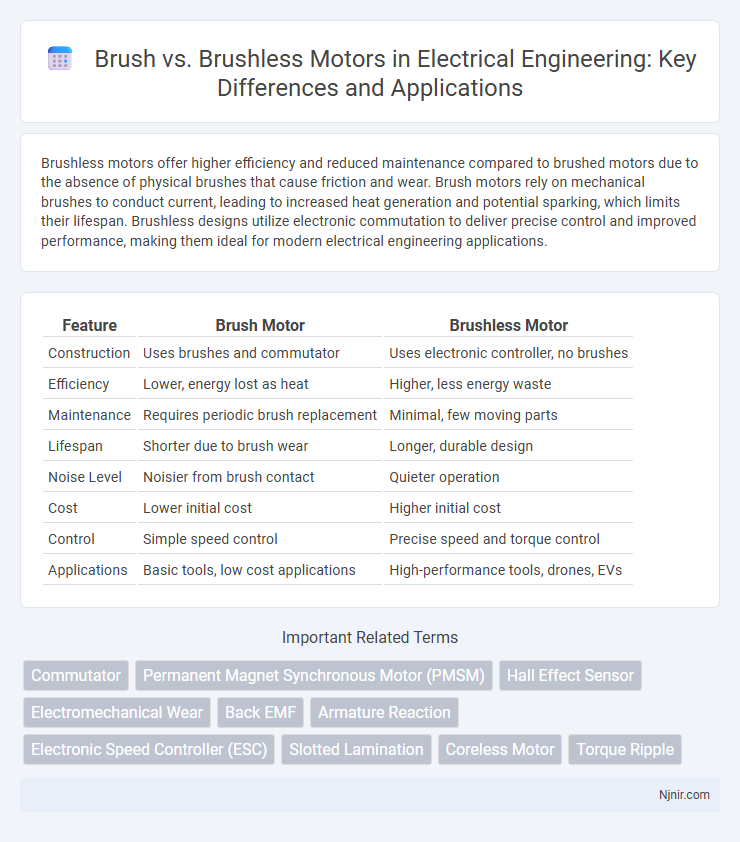

Table of Comparison

| Feature | Brush Motor | Brushless Motor |

|---|---|---|

| Construction | Uses brushes and commutator | Uses electronic controller, no brushes |

| Efficiency | Lower, energy lost as heat | Higher, less energy waste |

| Maintenance | Requires periodic brush replacement | Minimal, few moving parts |

| Lifespan | Shorter due to brush wear | Longer, durable design |

| Noise Level | Noisier from brush contact | Quieter operation |

| Cost | Lower initial cost | Higher initial cost |

| Control | Simple speed control | Precise speed and torque control |

| Applications | Basic tools, low cost applications | High-performance tools, drones, EVs |

Introduction to Brushed and Brushless Motors

Brushed motors feature carbon brushes that transfer electricity to the rotating armature, creating friction and wear that limit their lifespan and efficiency. Brushless motors use electronic controllers to switch current in the motor windings, improving performance, durability, and energy efficiency by eliminating mechanical brushes. Common in applications like power tools and drones, brushless motors offer higher torque-to-weight ratios and reduced maintenance compared to traditional brushed motors.

Fundamental Working Principles

Brush motors use carbon brushes to transfer electricity to the rotating armature, creating a magnetic field that interacts with stationary magnets to produce motion. Brushless motors eliminate brushes by using electronic controllers to switch current in the stator windings, resulting in higher efficiency and reduced mechanical wear. The fundamental difference lies in the method of commutation: mechanical in brush motors versus electronic in brushless motors.

Construction and Design Differences

Brush motors contain carbon brushes that maintain electrical contact with the rotating commutator, resulting in mechanical friction and wear; their simpler design often leads to bulkier construction and increased maintenance. Brushless motors eliminate brushes by using electronic controllers to switch current in the windings, enhancing durability and reducing size due to fewer moving parts. The brushless design integrates magnets on the rotor and windings on the stator, enabling higher efficiency, quieter operation, and longer lifespan compared to traditional brushed motors.

Efficiency and Performance Comparison

Brushless motors offer significantly higher efficiency compared to brushed motors, as they eliminate friction and voltage drops caused by brushes and commutators. This results in improved power output, longer lifespan, and reduced maintenance requirements. The superior performance of brushless motors is evident in faster speed control, smoother operation, and higher torque-to-weight ratios, making them ideal for applications demanding precision and reliability.

Maintenance Requirements and Longevity

Brushless motors require significantly less maintenance than brushed motors because they eliminate the brushes and commutator that wear out over time. This reduction in mechanical wear enhances the motor's longevity, often doubling the lifespan compared to traditional brushed motors. Maintenance demands for brushless motors are primarily limited to occasional bearing lubrication, leading to lower downtime and increased reliability in long-term use.

Cost Considerations and Market Availability

Brush motors generally offer lower upfront costs compared to brushless motors due to simpler design and manufacturing processes, making them attractive for budget-conscious buyers. Brushless motors provide higher efficiency and longer lifespan, which can reduce total ownership costs despite higher initial prices. Market availability shows brush motors are widespread in low-cost applications, while brushless motors dominate premium and industrial segments due to superior performance and reliability.

Applications in Modern Electrical Systems

Brushless motors dominate modern electrical systems due to their higher efficiency, longer lifespan, and lower maintenance compared to brushed motors. Applications include electric vehicles, drones, and industrial automation where precision control and reliability are critical. Brushed motors are still used in cost-sensitive or simpler applications like household appliances and power tools, benefiting from straightforward design and lower upfront cost.

Control Methods and Drive Circuitry

Brush motors use mechanical commutation with brushes and a commutator to switch current, resulting in simpler drive circuitry but increased wear and maintenance. Brushless motors rely on electronic commutation controlled by sensors or sensorless algorithms, enabling precise control methods such as field-oriented control (FOC) and pulse-width modulation (PWM). Advanced drive circuitry in brushless motors improves efficiency, torque control, and reduces electromagnetic interference compared to brushed motor designs.

Noise, Heat, and Reliability Factors

Brushless motors generate less noise due to the absence of brushes causing friction, resulting in quieter operation. They also produce less heat as their design minimizes energy loss and enhances efficiency, improving thermal management. Brushless motors offer superior reliability by reducing mechanical wear and eliminating brush maintenance, leading to longer lifespan and consistent performance.

Future Trends in Motor Technology

Brushless motors are increasingly dominating future motor technology trends due to their higher efficiency, reliability, and lower maintenance compared to brushed motors. Innovations in brushless motor control algorithms and materials are enabling improved performance in electric vehicles, drones, and industrial automation. The shift towards brushless technology supports the growing demand for energy-efficient, durable, and compact motor solutions in smart and sustainable applications.

Commutator

Brushless motors eliminate the commutator, reducing maintenance and improving efficiency compared to brushed motors that rely on a mechanical commutator for current switching.

Permanent Magnet Synchronous Motor (PMSM)

Permanent Magnet Synchronous Motors (PMSMs) in brushless designs offer higher efficiency, reduced maintenance, and improved torque density compared to traditional brushed motors.

Hall Effect Sensor

Brushless motors utilize Hall Effect sensors to precisely detect rotor position, enabling efficient commutation and improved performance compared to traditional brushed motors.

Electromechanical Wear

Brushless motors reduce electromechanical wear by eliminating physical brushes, resulting in longer lifespan and lower maintenance compared to brushed motors.

Back EMF

Brushless motors generate less Back EMF due to their electronic commutation system, resulting in higher efficiency and smoother operation compared to brushed motors.

Armature Reaction

Brushless motors eliminate armature reaction effects by using electronic commutation instead of physical brushes, resulting in higher efficiency and reduced maintenance compared to brushed motors.

Electronic Speed Controller (ESC)

Brushless Electronic Speed Controllers (ESCs) offer higher efficiency, precise motor control, and longer lifespan compared to brushed ESCs, which suffer from mechanical wear and reduced performance.

Slotted Lamination

Brushless motors with slotted lamination offer higher efficiency and reduced maintenance compared to brushed motors by minimizing electrical losses and enhancing magnetic flux control.

Coreless Motor

Coreless motors in brushless systems deliver higher efficiency, reduced vibration, and longer lifespan compared to traditional brushed motors with commutators.

Torque Ripple

Brushless motors exhibit significantly lower torque ripple compared to brushed motors, resulting in smoother and more efficient performance.

brush vs brushless Infographic

njnir.com

njnir.com